Method for deep denitrification of metaphase landfill leachate through single-stage SBR (Styrene Butadiene Rubber) post denitrification treatment

A landfill leachate and post-denitrification technology, which is applied in the field of start-up and stabilization of landfill leachate biological denitrification treatment, can solve the problems of increasing operating costs and effluent discharge that cannot meet the standard discharge, so as to reduce operating costs and reduce aeration , The effect of simple reaction device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

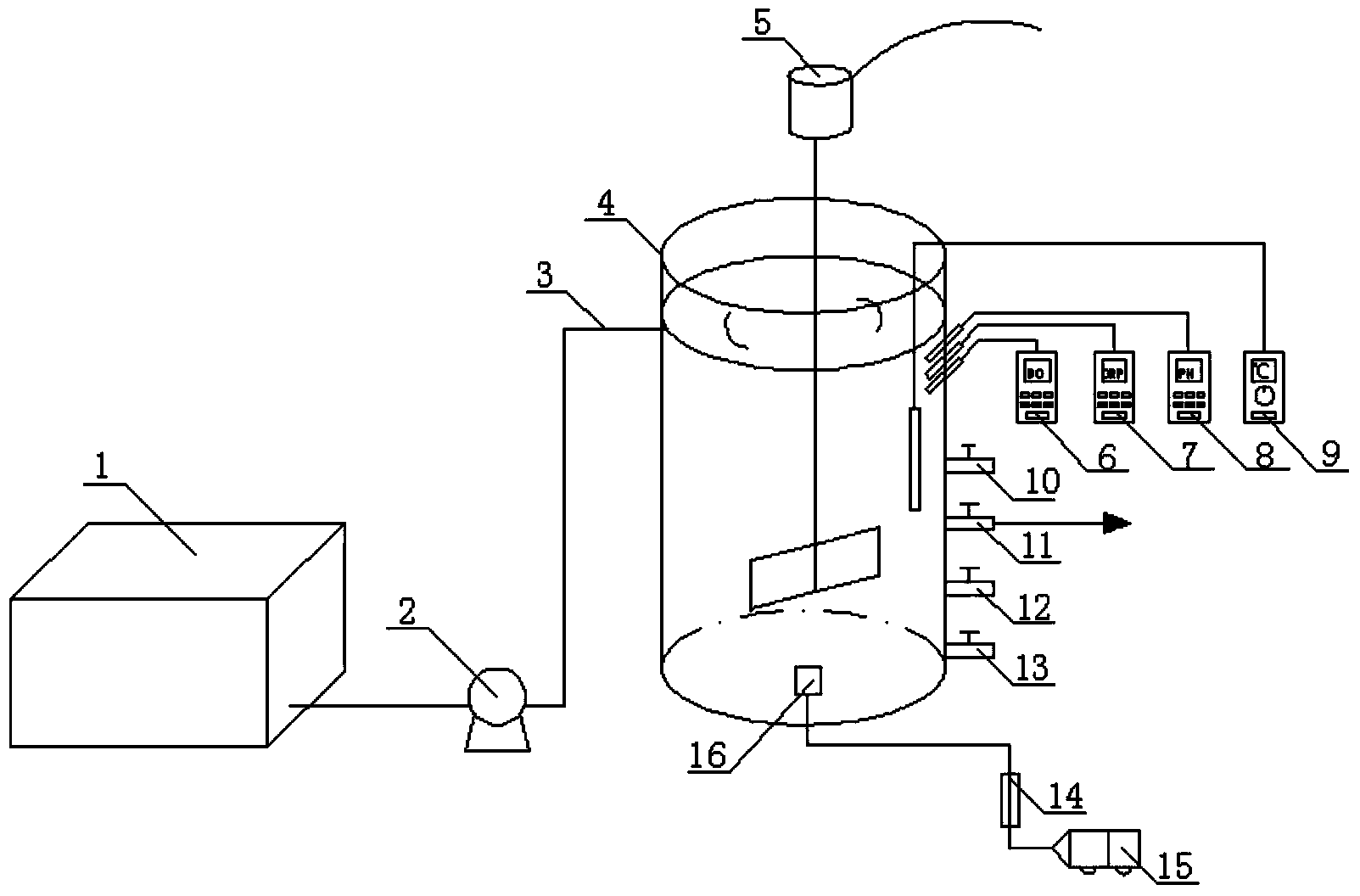

[0019] Such as figure 1 Shown is a single-stage SBR post-denitrification device used for deep denitrification of landfill leachate in the middle stage, including: water tank 1, water inlet pump 2, water inlet pipe 3, sequencing batch reactor (SBR) 4, mechanical agitation Device 5, Dissolved Oxygen Meter 6, ORP Meter 7, PH Meter 8, Temperature Control System 9, Sampling Ports 10 and 12, Drain Valve 11, Sludge Valve 13, Gas Flow Meter 14, Air Compression Pump 15, Aeration Head 16, etc.; water tank 1, water inlet pump 2, water inlet pipe 3 are connected in sequence, and the bottom of SBR reactor 4 is equipped with aeration head 16, and agitator 5 is used for mechanical stirring. Meter 14 and air compressor pump 15 are connected, dissolved oxygen measuring instrument 6, ORP measuring instrume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com