Method for extracting and separating ceramide in konjac flying powder

The technology of konjac fly powder and ceramide is applied in the field of extraction technology of plant active ingredients, which can solve the problems of thermal instability of active ingredients, large solvent consumption, long time consumption, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

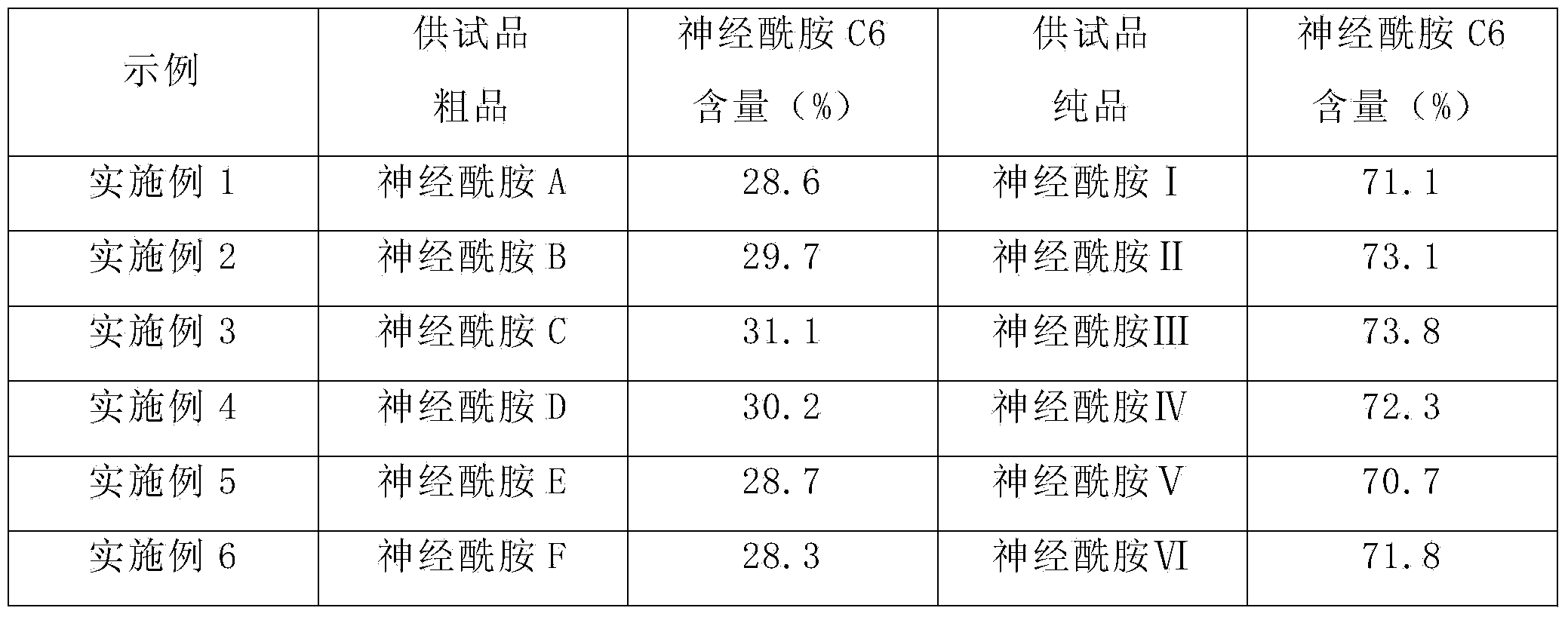

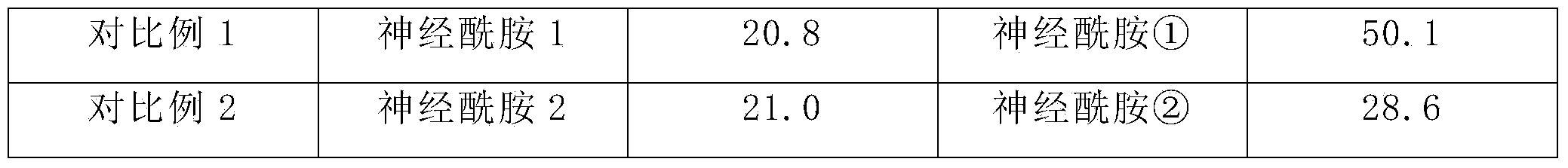

Examples

Embodiment 1

[0020] (1) Dry 20 parts by mass of konjac fly powder, add ethanol with a concentration of 95% by volume, and extract by ultrasonic shaking at 45°C for 20 minutes. Filter the extract while hot, and remove part of the solvent by rotary evaporation to obtain a paste with a density of 1.15 The amount of ethanol used is 5 times the quality of konjac fly flour;

[0021] (2) Put the paste obtained in step (1) into a supercritical extraction kettle, using CO 2 Supercritical fluid extraction and separation, extraction temperature is 35℃, extraction pressure is 15Mpa, extraction time is 0.5 hours, CO 2 The flow rate is 10L / h; the obtained supercritical CO containing extract 2 The fluid is analyzed under reduced pressure to separate the extraction product, the separation temperature is 35°C, the separation pressure is 5Mpa, and the collected extraction product is the crude ceramide A.

[0022] (3) Put the crude ceramide obtained in step (2) into the supercritical extraction kettle again, perfo...

Embodiment 2

[0024] (1) Dry 20 parts by mass of konjac fly powder, add 95% ethanol by volume percentage, and extract by ultrasonic shaking at 50°C for 25 minutes. Filter the extract while hot, and use rotary evaporation to remove part of the solvent to obtain a paste with a density of 1.15 The amount of ethanol is 6 times the quality of konjac fly flour;

[0025] (2) Put the paste obtained in step (1) into a supercritical extraction kettle, using CO 2 Supercritical fluid extraction separation, extraction temperature is 40℃, extraction pressure is 25Mpa, extraction time is 1 hour, CO 2 The flow rate is 12L / h; the obtained supercritical CO containing extract 2 The fluid is analyzed under reduced pressure to separate the extraction product, the separation temperature is 40°C, the separation pressure is 7Mpa, and the collected extraction product is the crude ceramide B.

[0026] (3) Put the crude ceramide obtained in step (2) into the supercritical extraction kettle again, perform secondary extracti...

Embodiment 3

[0028] (1) Dry 20 parts by mass of konjac fly powder, add 95% ethanol by volume, and extract by ultrasonic shaking at 55°C for 30 minutes. Filter the extract while hot, and use rotary evaporation to remove part of the solvent to obtain a paste with a density of 1.15 The amount of ethanol is 7 times the quality of konjac fly flour;

[0029] (2) Put the paste obtained in step (1) into a supercritical extraction kettle, using CO 2 Supercritical fluid extraction separation, extraction temperature is 45℃, extraction pressure is 35Mpa, extraction time is 1.5 hours, CO 2 The flow rate is 15L / h; the obtained supercritical CO containing extract 2 The fluid is analyzed under reduced pressure to separate the extraction product, the separation temperature is 45°C, and the separation pressure is 10Mpa. The collected extraction product is the crude ceramide C.

[0030] (3) Put the crude ceramide obtained in step (2) into the supercritical extraction kettle again, perform secondary extraction and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com