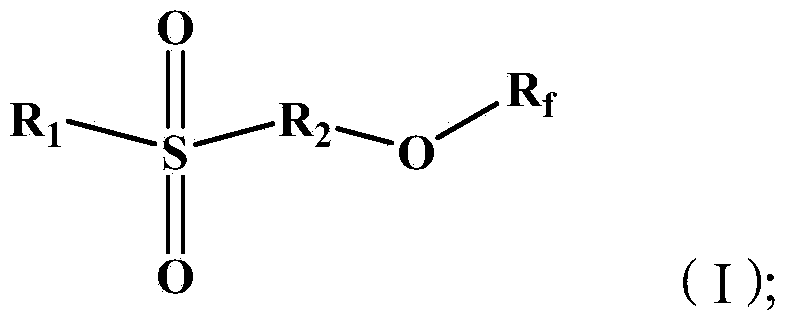

Hydrofluoroether sulfones compound and preparation method thereof as well as lithium-ion battery electrolyte

A lithium-ion battery and compound technology, applied in the field of lithium-ion batteries, can solve the problems of high melting point and high viscosity, and achieve the effects of high electrical conductivity, improved pressure resistance and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

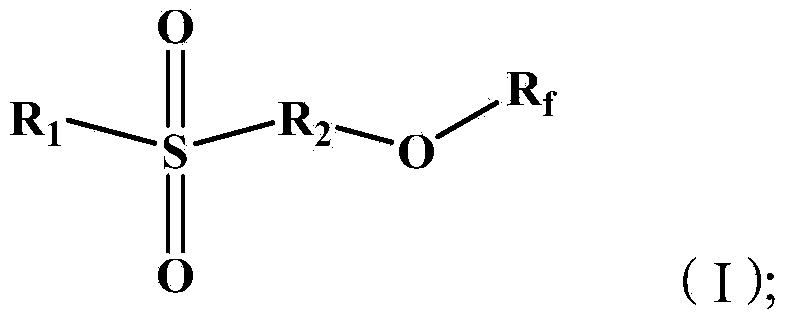

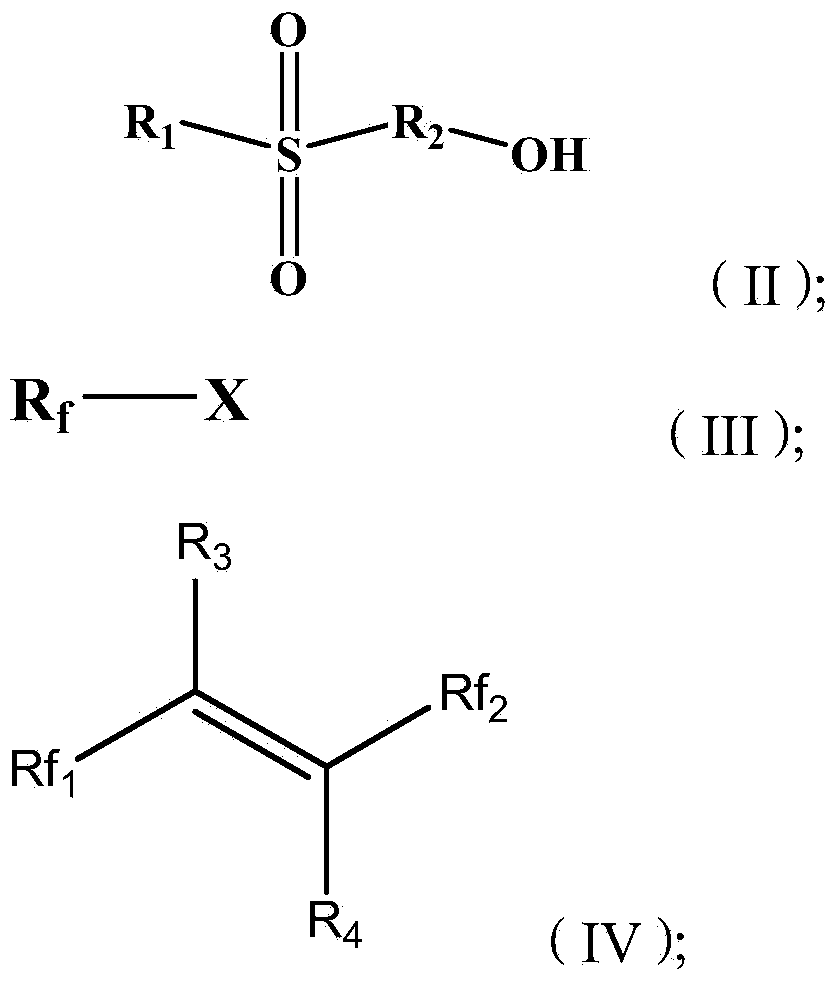

Method used

Image

Examples

Embodiment 1

[0069] 1.1 161g (2mol) Cl-CH 2 CH 2 -OH was added to a 0.5L flask, 28g (0.5mol) potassium hydroxide was added under stirring, and then the system gas was replaced with nitrogen three times, heated to 35°C, and 100.8g (2.1mol) CH 3 -SH was slowly added dropwise to the flask. During the dropping process, the temperature of the system was maintained between 30°C and 40°C with a room temperature water bath. After the dropping was completed, stirring was continued for 1 hour at room temperature, and the mixture was rectified under reduced pressure to obtain the product hydroxyethyl Methyl sulfide has a purity of 99.9% and a yield of 84%.

[0070] 1.2 Add 184g (2mol) of the hydroxyethyl methyl sulfide obtained in 1.1 to a 0.5L flask, slowly add 128g (4mol) of hydrogen peroxide dropwise under vigorous stirring, and keep the reaction by cooling water in a room temperature water bath during the dropwise addition The temperature is between 20°C and 30°C. After the dropping is completed, the...

Embodiment 2

[0078] Add 248g (2mol) of hydroxyethyl methyl sulfone obtained in 1.2 to a 0.5L autoclave, add 28g (2mol) of potassium hydroxide under stirring conditions, seal the reactor, evacuate, and replace the system gas with nitrogen three times , Then vacuumize, feed in 0.1Mpa hexafluoropropylene, heat to 60°C, intermittently feed in hexafluoropropylene, keep the pressure in the kettle at 0.3-0.4MPa, stop the reaction when the pressure in the reactor no longer changes, and use water for the mixture After washing and phase separation, add 10ml of bromine to the organic phase, stir for 2 hours at room temperature, and then add sodium thiosulfate solution to wash until it is neutral. After phase separation, rectify to obtain the formula (I-2) with a purity of 99.9% The yield of hydrofluoroether sulfone compounds is 70%.

[0079]

[0080] The hydrofluoroether sulfone compound represented by formula (I-2) obtained in Example 2 was tested by nuclear magnetic resonance, and its proton nuclear m...

Embodiment 3

[0082] Add 248g (2mol) of hydroxyethyl methyl sulfone obtained in 1.2 to a 0.5L autoclave, add 28g (2mol) of potassium hydroxide under stirring conditions, seal the reactor, evacuate, and replace the system gas with nitrogen three times , Then vacuumize, feed in 0.1Mpa tetrafluoropropylene, heat to 60℃, and intermittently feed in 200g (2mol) tetrafluoropropylene, keep the pressure in the kettle at 0.3~0.4MPa, and stop the reaction when the pressure in the reactor no longer changes , The mixture was washed with water, after phase separation, 10ml bromine was added to the organic phase, stirred at room temperature for 2h, and then sodium thiosulfate solution was added to wash until it became neutral. After phase separation, rectified to obtain the formula (I-3) with a purity of 99.9% The yield of the hydrofluoroether sulfone compound shown in) was 71%.

[0083]

[0084] The hydrofluoroether sulfone compound represented by formula (I-3) obtained in Example 3 was tested by nuclear ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com