Preparation of anionic modified nature macromolecule polymer flocculant

An anionic flocculant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, water/sewage treatment, etc. High conversion rate, good effect, less dosage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

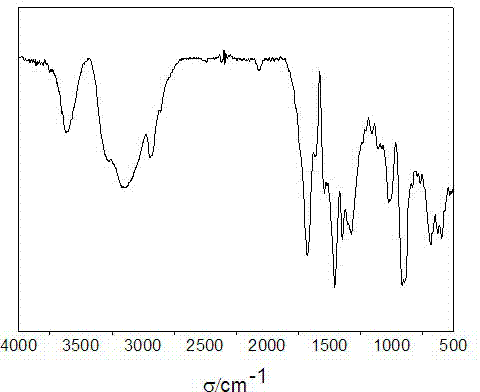

Image

Examples

Embodiment Construction

[0020] 1. Preparation of anionic modified natural polymer flocculant:

[0021] Take 20-30% starch (may or potato starch) and disperse it in 50-100% distilled water, add NaCl, stir and mix evenly, adjust the pH to 10, add epichlorohydrin, and react at 30°C for 3 hours to obtain the modified product. permanent starch.

[0022] Disperse 2-4g of modified starch in 60-90g of distilled water, stir and disperse for 10 minutes, then heat up to 95°C under constant stirring in the heating and cooling equipment, keep warm and gelatinize for 20min, then cool down to 35°C and pass nitrogen gas for 20- After 30 minutes, add 7-9g of acrylamide, continue to pass nitrogen gas for 15 minutes, add the initiator ammonium persulfate (added at 5%), and the system will initiate polymerization after 20-30 minutes. The reaction was carried out at 45°C for 4 hours.

[0023] After completion, the reaction system mixture was precipitated with acetone and washed with ethanol, and the crude product was v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com