Method for rapidly measuring trace boron impurities in polysilicon

A polysilicon and boron impurity technology, which is applied in the direction of measuring devices, preparation of test samples, and material analysis by electromagnetic means, can solve the problems of controlling the heating temperature within 120°C, large memory effect, and large consumption of reagents, etc. To achieve the effect of solving the long time-consuming of sample dissolution, accelerating the reaction of sample dissolution and shortening the time of sample testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] (1) Weigh the polysilicon sample as the sample. The industrial silicon sample is in the form of powder or block, wherein the particle size of the powder is 4-100 mesh, the diameter of the block is 2mm-6mm, and the mass weighed is 0.2 g;

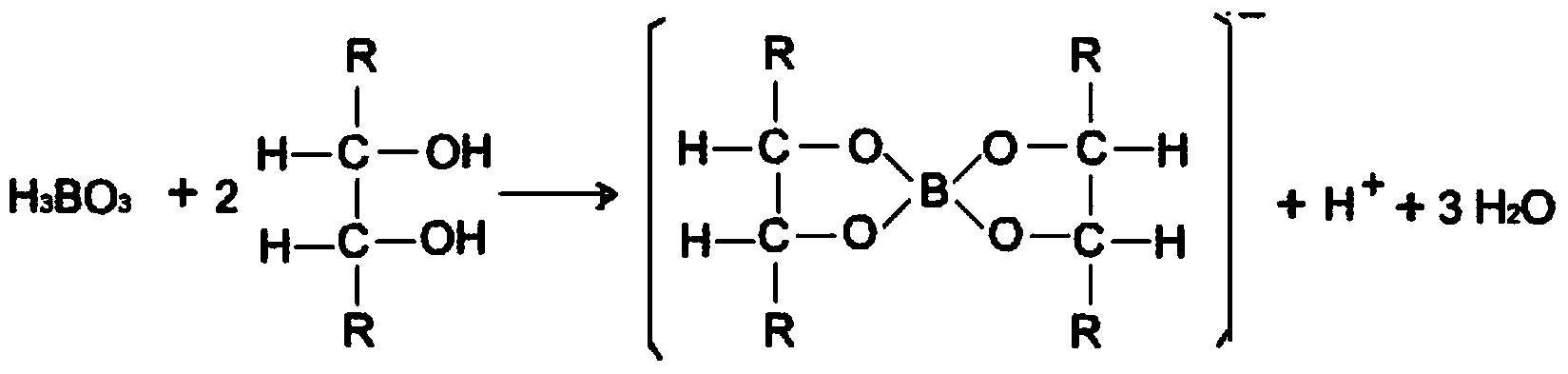

[0063] (2) Add complexing agent mannitol solution to the above sample, the concentration of the complexing agent mannitol solution is 2.5g / L, and the volume is 0.3ml;

[0064] (3) Add K to the above sample that has been added complexing agent 2 CO 3 solution to form the first solution sample, the K 2 CO 3 The solution concentration is 5g / L and the volume is 0.3ml;

[0065] (4) After adding hydrofluoric acid to the above-mentioned first solution sample, slowly drop nitric acid into it to dissolve the first solution sample. The concentration of the hydrofluoric acid is 40%, and the volume is 4ml. The concentration of the nitric acid 69%, the volume is 1ml;

[0066] (5) After the above-mentioned first solution sample is completely d...

Embodiment 2

[0072] (1) Weigh the polysilicon sample as the sample. The industrial silicon sample is in the form of powder or block, wherein the particle size of the powder is 4-100 mesh, the diameter of the block is 2mm-6mm, and the mass weighed is 0.2 g;

[0073] (2) Add complexing agent mannitol solution to the above sample, the concentration of the complexing agent mannitol solution is 2.5g / L, and the volume is 0.4ml;

[0074] (3) Add K to the above sample that has been added complexing agent 2 CO 3 solution to form the first solution sample, the K 2 CO 3 The solution concentration is 5g / L, and the volume is 0.5ml;

[0075] (4) After adding hydrofluoric acid to the above-mentioned first solution sample, slowly drop nitric acid to dissolve the first solution sample. The concentration of the hydrofluoric acid is 40%, and the volume is 5ml. The concentration of the nitric acid 70%, the volume is 1.5ml;

[0076] (5) After the above-mentioned first solution sample is completely dissol...

Embodiment 3

[0082] (1) Weigh the polysilicon sample as the sample. The industrial silicon sample is in the form of powder or block, wherein the particle size of the powder is 4-100 mesh, the diameter of the block is 2mm-6mm, and the weighed mass is 0.2 g;

[0083] (2) Add complexing agent mannitol solution to the above sample, the concentration of the complexing agent mannitol solution is 2.5g / L, and the volume is 0.5ml;

[0084] (3) Add K to the above sample that has been added complexing agent 2 CO 3 solution to form the first solution sample, the K 2 CO 3 The solution concentration is 5g / L and the volume is 0.7ml;

[0085] (4) After adding hydrofluoric acid to the first solution sample, slowly drop nitric acid to dissolve the first solution sample. The concentration of the hydrofluoric acid is 40%, and the volume is 6ml. The concentration of the nitric acid 71%, the volume is 2ml;

[0086] (5) After the above-mentioned first solution sample is completely dissolved, move the solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com