Method for producing silicon fertilizer through rice hulls

A technology of rice husk and silicon fertilizer, applied in the field of agricultural science, can solve problems that have not been mentioned by scholars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

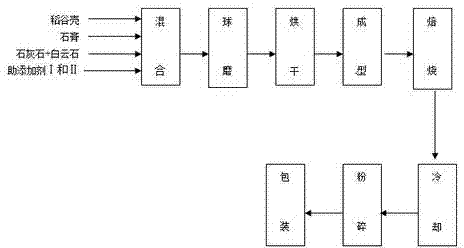

Method used

Image

Examples

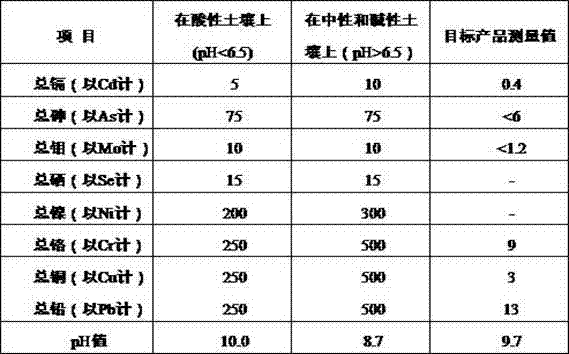

Embodiment 1

[0029] A fertilizer company in Shenzhen is a large-scale joint-stock enterprise that produces compound fertilizers. Using this process to produce silicon fertilizer, the raw material compatibility (by mass percentage) used is: rice husk 55%, gypsum 27%, limestone + dolomite 14.5% (the mass ratio of limestone to dolomite is 2.5:1), Additives I and II are added in an amount of 3.5%, among which additive I is potassium feldspar + muscovite (mass ratio 1:1); additive II is mirabilite + salt (mass ratio 1:1), additives I and II The mass ratio between them is also 1:1. The technological process is as follows: fully mix the above mineral raw materials, and perform ball milling until the particle size is below 0.074mm; then dry the mixed material until the moisture content is less than 5%; the dried powder is formed into a particle size of about 2cm pellets, and enter the activation kiln for calcination, the temperature is controlled at 1100°C, and the calcination time is 65 minutes....

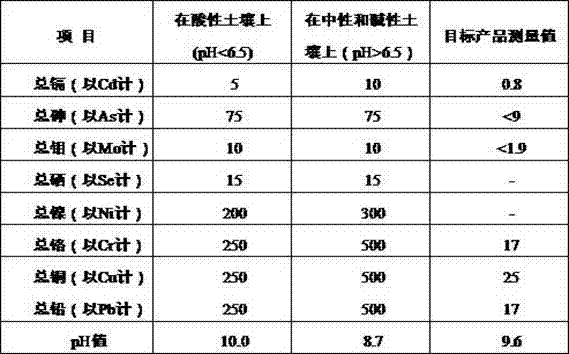

Embodiment 2

[0033] A fertilizer company in Shanxi adopts this process to produce silicon fertilizer. The material compatibility (in terms of mass percentage) is: rice husk 57%, gypsum 31%, limestone + dolomite 10% (the mass ratio of limestone to dolomite is 2.3:1) , the amount of auxiliary additives I and II is 2%, of which auxiliary additive I is illite + potassium chloride (mass ratio 1:1); auxiliary additive II is table salt + sodium fluoride (mass ratio 1:1), auxiliary The mass ratio between additives I and II is 1:2. The process flow is as follows: fully mix the above mineral raw materials, and perform ball milling until the particle size is below 0.090mm; then dry the mixed material until the moisture content is less than 6%; the dried powder is molded and processed into a particle size of about 1.5cm The pellets are put into the activation kiln for calcination, the temperature is controlled at 1070°C, and the calcination time is 80 minutes. The roasted pellets are cooled and crush...

Embodiment 3

[0037] A fertilizer company in Guangdong is a large private enterprise that produces soil conditioners. Using this process to produce silicon fertilizer, the production cost has dropped by nearly 54%. The raw material compatibility (in terms of mass percentage) used is: rice husk 51%, gypsum 25%, limestone + dolomite 20.5% (including limestone and dolomite) The mass ratio is 2.7:1), and the addition amount of auxiliary additives I and II is 3.5%, among which auxiliary additive I is illite + muscovite (mass ratio 1:1); auxiliary additive II is mirabilite + sodium fluoride (mass ratio 1 : 1), the mass ratio between auxiliary additives I and II is also 1:2.05. The process flow is as follows: fully mix the above-mentioned mineral raw materials, and perform ball milling until the particle size is below 0.074mm; then dry the mixed material until the moisture content is less than 4%; the dried powder is molded and processed into a particle size of about 2.2cm The pellets are put int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com