A kind of special fertilizer for long-acting dry farming sweet potato and preparation method thereof

A sweet potato special fertilizer, long-term technology, applied in the application, fertilization device, fertilizer mixture and other directions, can solve the problems of high price of slow-release long-acting fertilizer, easy loss of ordinary fertilizer, complicated process, etc., to reduce water transpiration and cost. Low, simple preparation process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A special fertilizer for long-acting dry-farmed sweet potatoes, the specific raw materials and preparation method are as follows:

[0020] (1), prefabricated fertilizer core: 200kg of nutrient P 2 o 5 40% powdered heavy superphosphate, 480kg of K 2 Potassium sulfate with an O content of 50%, 55kg of powdered urea, and 25kg of fulvic acid are put into a stirring mixer and mixed evenly.

[0021] The spray granulation process is used for granulation, specifically: the uniformly mixed powdered triple superphosphate, potassium sulfate, powdered urea, and additives are fed into the granulation drum. Melt 100kg of urea, spray it into the fertilizer mixture in the granulation cylinder by spray granulation process, then dry it at 90°C and sieve it into a spherical granular fertilizer core with a particle size of 2.5-3.5mm. The weight ratios of nitrogen fertilizer, phosphorus fertilizer and potassium fertilizer in the fertilizer core calculated by pure nitrogen, phosphorus pen...

Embodiment 2

[0028] The special fertilizer for long-acting dry-farming sweet potato containing trace element zinc can be prepared by the following steps.

[0029] (1) Prefabricated fertilizer core: 50kg powdered urea, 110kg N-P 2 o 5 -K 2 O powdery monoammonium phosphate with a nutrient content of 12-55-0, 480kg of K 2 Potassium sulfate with an O content of 50%, 42kg of zinc sulfate with a zinc content of 24%, and 38kg of fulvic acid are mixed evenly. The above-mentioned fertilizers that have been mixed evenly are sent into the granulation drum.

[0030] Melt 140kg of urea, and use the spray granulation process to spray all the melted 140kg of urea into the fertilizer mixture in the granulation tube, and control to achieve a suitable particle size, which is a special fertilizer for sweet potatoes with a nutrient content of 11.7-7-27.9 (Also contains 1% trace element zinc). The granulation process can also adopt drum steam granulation or disc granulation. In the drying process, the dr...

Embodiment 3

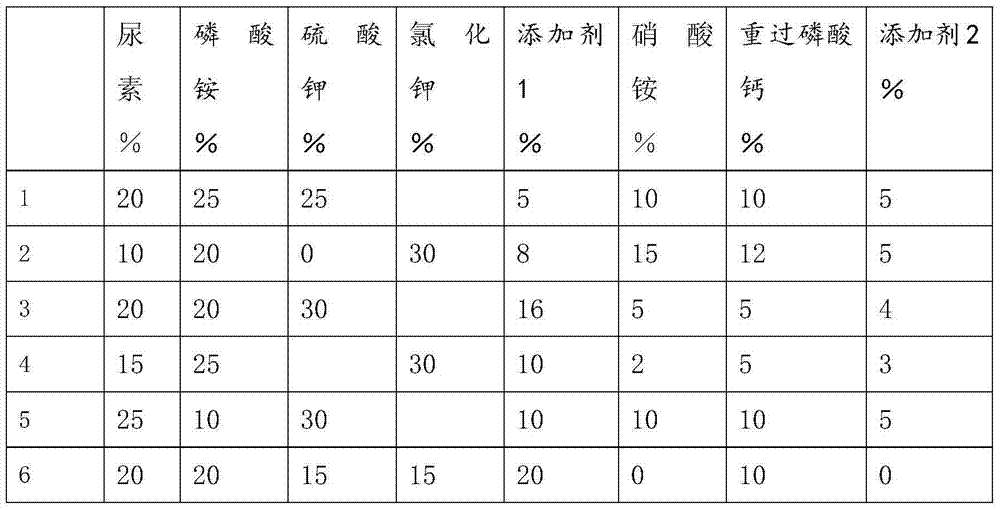

[0036] Under the situation that manufacturing process is identical with embodiment 1 and 2, adjust the kind and proportioning of material, the different fertilizer inner cores of making, as shown in table 1:

[0037] Table 1 Fertilizer core combination ratio selection

[0038]

[0039] The additive 1 is selected from one or more mixtures of fulvic acid, urease inhibitors and light calcium carbonate; the additive 2 is a compound micro-fertilizer selected from zinc sulfate, manganese sulfate, ferrous sulfate and boric acid one or a combination of several.

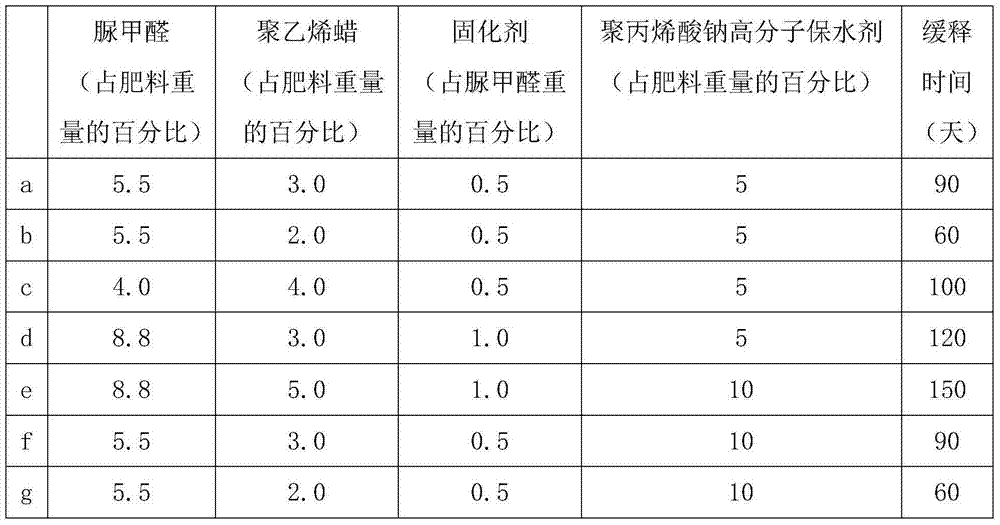

[0040] On the outside of the fertilizer core, the thickness of the coating coating and the water-retaining agent layer sprayed are different, and the material ratio of the curing agent in the coating coating is different, which can produce special fertilizers with different slow-release time and water retention capacity (see Table 2 ).

[0041] Table 2 Combination ratio selection of coating coating and water-retaining ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com