Alkylate treatment method

A treatment method, an alkylation technology, applied in organic chemistry, adsorption purification/separation, etc., can solve problems such as separation system corrosion, achieve low equipment investment, solve corrosion, and simple and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

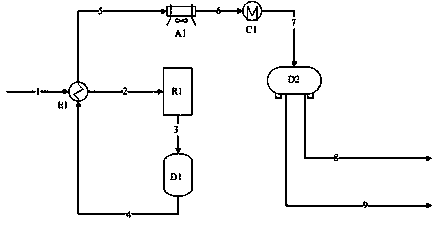

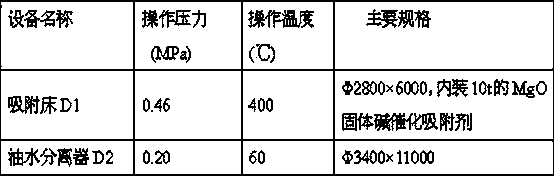

[0021] The specific implementation is as figure 1 and figure 2 The device flow shown. The raw material 1 is sent into the reaction system after exchanging heat with the reaction product gas 4 first, and the obtained alkylation product 3 contains impurities such as formic acid and acetic acid, and the alkylation product 3 first enters the adsorption bed D1 (this adsorption bed can be an independent adsorption bed, It can also be filled with adsorbent in the reactor), after being deacidified by high-temperature catalytic reaction, it is sent to the subsequent cooling system, and after being cooled to 60°C by the inlet and outlet heat exchanger E1, air cooler A1, and water cooler C1, it enters the oil-water separation tank D2 , the oil phase 8 separated by the oil-water separation tank D2 is sent to the subsequent aromatics separation system, and the water phase 9 separated by the oil-water separation tank D2 is sent to the subsequent sewage treatment system.

[0022] Table 1 ...

Embodiment 2

[0025] The specific implementation is as figure 1 and figure 2 The device flow shown.

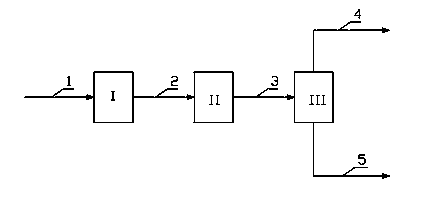

[0026] figure 1 In the process flow of an alkylation product treatment method shown, the gas phase reaction product 1 first enters the high-temperature deacidification system I to remove organic acids, and the deacidified reaction product 2 is sent to the reaction product cooling system II to be cooled to the liquid phase , the liquid phase reaction product 3 is sent to the oil-water separator III, the oil phase 4 separated in the oil-water separator III is sent to the subsequent separation system, and the separated water phase 5 is sent to the subsequent sewage treatment system.

[0027] figure 2 The industrial device process of an alkylation product treatment method is shown. The raw material 1 is first exchanged with the reaction product gas 4 and then sent to the reaction system. The obtained alkylation product 3 contains impurities such as formic acid and acetic acid. The alkylat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com