Method for preparing aglycone and secondary glucoside through various glycoside hydolysis assisted by macroporous adsorption resin

A technology of pore adsorption and secondary glycosides, applied to secondary glycosides and aglycones, can solve the problems of high cost, lack of industrialization, and limited usage, and achieve the effect of increasing yield and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

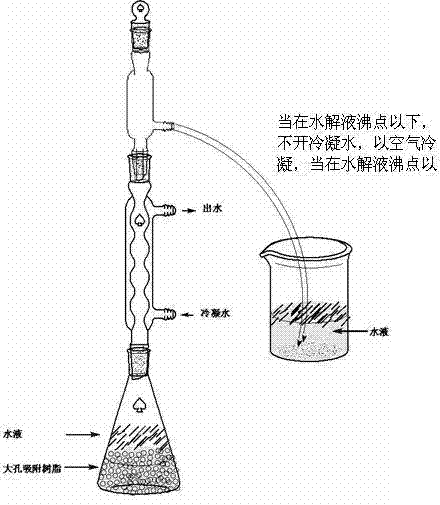

preparation example Construction

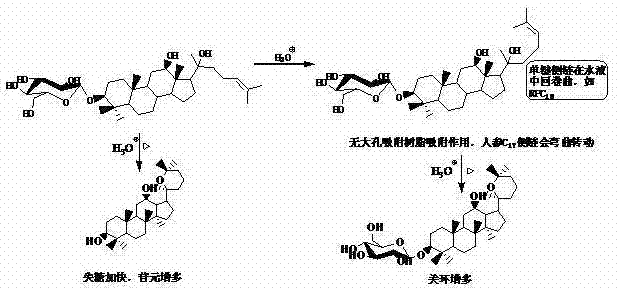

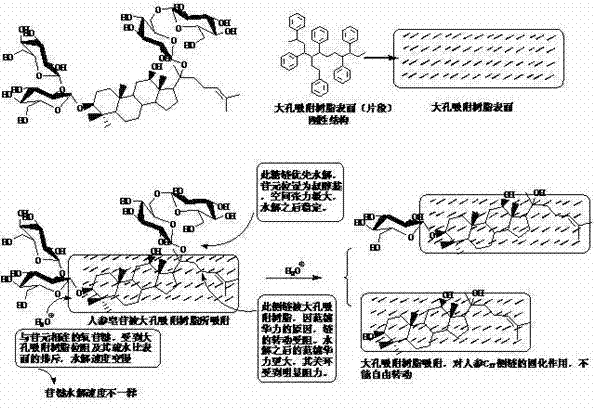

[0028] Due to the glycoside compounds involved, there are many types and a large number. Therefore, each glycoside compound cannot be illustrated, but in order to further understand the present invention, the role played by the macroporous adsorption resin in the hydrolysis process of glycosides is classified and described, and the examples are as follows:

[0029] The first category: for easily oxidized aglycone, the macroporous adsorption resin can absorb, disperse and settle to prevent its oxidation.

[0030] Example 1:

Embodiment 1

[0032] Example 2:

Embodiment 2

[0034] Example 3:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com