Low-odor and low-emission acrylonitrile-butadiene-styrene (ABS) composition and preparation method thereof

A low-emission, low-odor technology, applied in the field of low-odor, low-emission ABS composition and its preparation, can solve the problems of limiting product color, material toughness, etc., to achieve improved compatibility, low cost, and effective odor removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

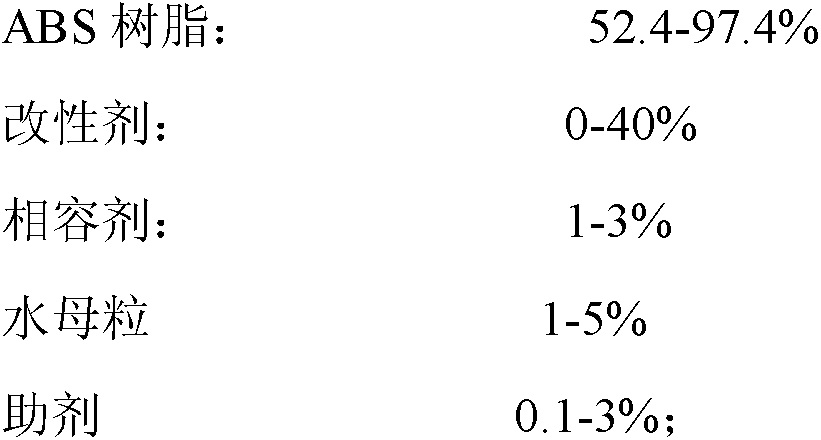

Method used

Image

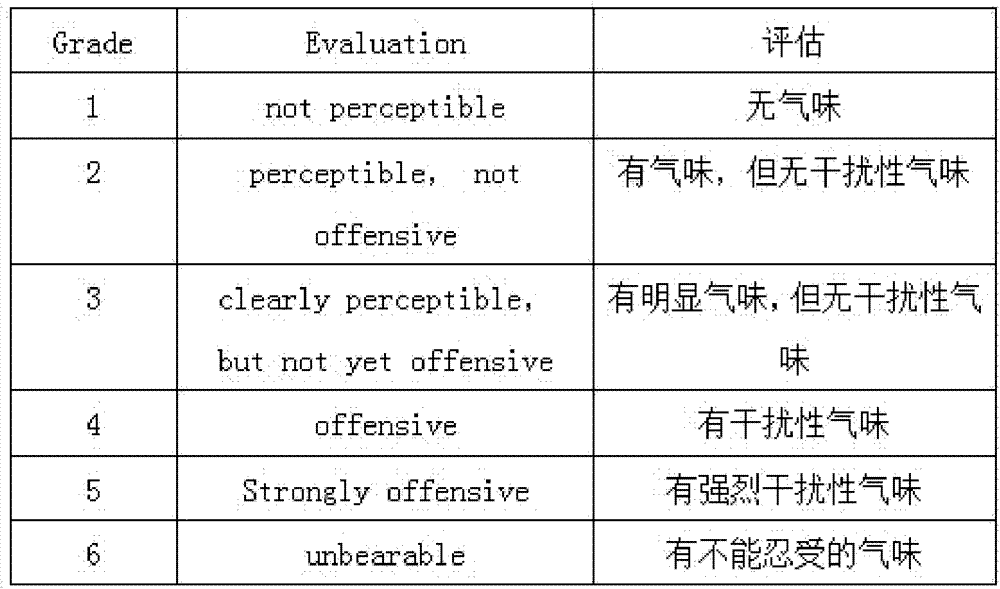

Examples

preparation example Construction

[0038] Preparation of jellyfish pellets:

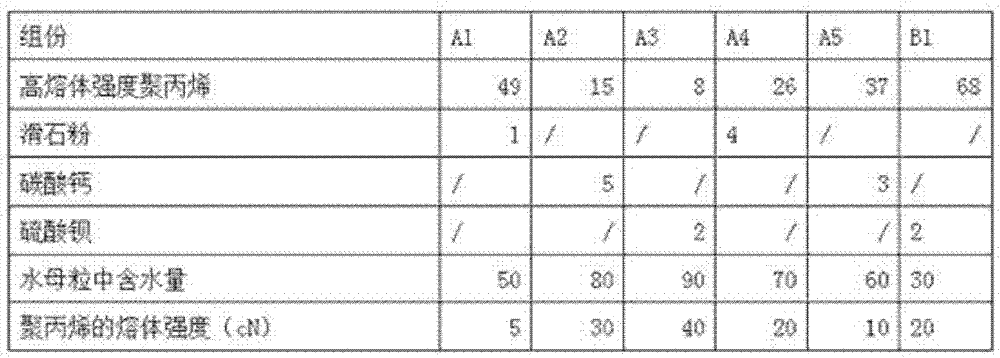

[0039] High melt strength polypropylene with different melt strength and mineral filler (talcum powder, calcium carbonate or barium sulfate) are fully mixed according to the proportion shown in Table 1, extruded strip polypropylene in the extruder, and then Shred it into polypropylene pre-expanded granules; use water as a foaming agent to foam the polypropylene pre-expanded granules to prepare expanded polypropylene with high melt strength; Polypropylene and water were mixed in a high-speed mixer for 5-10 minutes. By controlling the mixing time, jellyfish particles with the water content shown in Table 1 were prepared and released for use.

[0040] Each component content (weight percent) of table 1 jellyfish grain

[0041]

Embodiment 1

[0043] A low odor, low emission ABS composition, its raw material formula is as shown in table 3, and its preparation method may further comprise the steps:

[0044] Weigh each component according to the weight percentage, mix in the high mixer for 1-3min; mix evenly to obtain the premix; put the premix in the main feeding port of the twin-screw extruder, Add jellyfish pellets, melt extrude, then granulate and cool to obtain ABS composition. Determination of its odor and volatile content, the specific data are listed in Table 4.

[0045] Among them, the ABS resin is selected from 121H of LG Chem, and the compatibilizer PP-g-MAH is selected from ST-9 of Nanjing Sutai Polymer Technology Co., Ltd.

Embodiment 2

[0047] A low smell, low emission ABS composition, its raw material formula is as shown in table 3, and its preparation method is with embodiment 1:

[0048] Among them, the ABS resin is selected from Takahashi's ABS8434, the compatibilizer PP-g-MAH is selected from ST-9 of Nanjing Plastic Technology Polymer Technology Co., Ltd., and the modifier is a maleimide heat-resistant modifier. MS-NB selected from DENKA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com