Weather-resistant PC (Polycarbonate) material and preparation method thereof

A technology of antioxidant and chlorinated polyethylene, which is applied in the field of weather-resistant PC materials and their preparation, can solve problems such as limiting the scope of use, and achieve the effects of good processability and mechanical properties, good compatibility, and good oil resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Dry the bisphenol A polycarbonate at 120° C. for 6 hours to obtain a dried bisphenol A polycarbonate.

[0026] (1) Weigh 66 kg of dry bisphenol A polycarbonate, 10 kg of chlorinated polyethylene, 10 kg of polyisobutylene, 10 kg of polyethylene, 8 kg of maleic anhydride grafted polypropylene, 8 kg of dibutyl hydroxytoluene and Diphenyl phosphite 2kg;

[0027] (2) Add the raw materials weighed in step (1) into the high mixer, control the mixing temperature at 80°C, and the mixing time is 5 minutes, add the mixed materials into the twin-screw extruder, pass Twin-screw extruder extrusion, granulation;

[0028] The temperature of each zone of the screw is: 130°C in the first zone, 150°C in the second zone, 180°C in the third zone, 210°C in the fourth zone, and 220°C in the fifth zone.

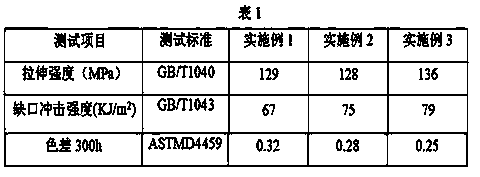

[0029] The performance test results of the prepared materials are shown in Table 1.

Embodiment 2

[0031] Dry the bisphenol A polycarbonate at 130° C. for 6 hours to obtain a dried bisphenol A polycarbonate.

[0032] (1) Weigh 80 kg of dry bisphenol A polycarbonate, 20 kg of chlorinated polyethylene, 15 kg of polyisobutylene, 10 kg of polyethylene, 10 kg of maleic anhydride grafted polypropylene, 5 kg of dibutyl hydroxytoluene and Diphenyl phosphate 3 kg;

[0033] (2) Add the raw materials weighed in step (1) into the high mixer, control the mixing temperature at 100°C, and the mixing time is 3 minutes, add the mixed materials into the twin-screw extruder, pass Twin-screw extruder extrusion, granulation;

[0034] The temperature of each zone of the screw is: 130°C in the first zone, 150°C in the second zone, 180°C in the third zone, 210°C in the fourth zone, and 220°C in the fifth zone.

[0035] The performance test results of the prepared materials are shown in Table 1.

Embodiment 3

[0037] Dry the bisphenol A polycarbonate at 120° C. for 6 hours to obtain a dried bisphenol A polycarbonate.

[0038] (1) Weigh 70 kg of dry bisphenol A polycarbonate, 15 kg of chlorinated polyethylene, 10 kg of polyisobutylene, 8 kg of polyethylene, 10 kg of maleic anhydride grafted polypropylene, 5 kg of dibutyl hydroxytoluene and Diphenyl phosphite 2kg;

[0039] (2) Add the raw materials weighed in step (1) into the high mixer, the mixing temperature is controlled at 90°C, and the mixing time is 3 minutes, and the mixed materials are added to the twin-screw extruder, passed through Twin-screw extruder extrusion, granulation;

[0040] The temperature of each zone of the screw is: 140°C in the first zone, 170°C in the second zone, 200°C in the third zone, 220°C in the fourth zone, and 220°C in the fifth zone.

[0041] The performance test results of the prepared materials are shown in Table 1.

[0042] Table 1

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com