Method for curing loose coral sand by utilizing microorganisms

A technology of coral sand and microorganisms, applied in the field of chemistry, can solve problems such as no one cares about, and achieve the effects of solving high transportation costs, improving reproductive capacity, and being convenient to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Acclimatization, cultivation and preservation of bacteria

[0029] The culture medium was prepared, the composition of the culture medium was shown in Table 1, and the solvent was water.

[0030] Table 1 Medium composition

[0031] Element

Yeast extract

Sodium chloride

Nickel chloride (hexahydrate)

Manganese chloride (tetrahydrate)

content

20g / L

20g / L

10 / 20 / 30 / 35g / L

23.8mg / L

13.9mg / L

[0032] Inoculate Bacillus pasteurii into the medium prepared according to Table 1 (in which the sodium chloride content is 10g / L), and culture at 25±2°C for 24h; then inoculate until the sodium chloride is 20g / L medium for 24 hours, and then in the medium with a sodium chloride concentration of 30g / L and 35g / L for 24 hours, until the activity of the bacterial liquid is >2mM·min under the condition of a sodium chloride concentration of 35g / L -1 , that is, stop the acclimatization culture; then centrifuge the bacteria...

Embodiment 2

[0035] Solidification of coral sand

[0036] Coral sand is a special type of rock-soil medium developed in tropical marine environments. It is mainly composed of coral debris and other marine biological debris, with high calcium carbonate content. The SEM scanning photos of coral sand are as follows: figure 1 shown.

[0037] The solidification method of coral sand: the calcium chloride solution that concentration is 2mol / L and the urea solution of 2mol / L are mixed in equal volume, then the bacterium liquid that embodiment 1 makes and the mixed solution containing calcium chloride and urea press 1 : 2 volume ratio mixed to get a mixed solution, and then inject the mixed solution into the coral sand from the upper part, the injection amount is equivalent to 1.5 times of the pore volume of the coral sand, and naturally discharge the liquid from the lower part, and control the outflow rate to 2-10mL / min, injected once a day for 3-6 consecutive days. Due to the consideration of ...

Embodiment 3

[0040] strength test

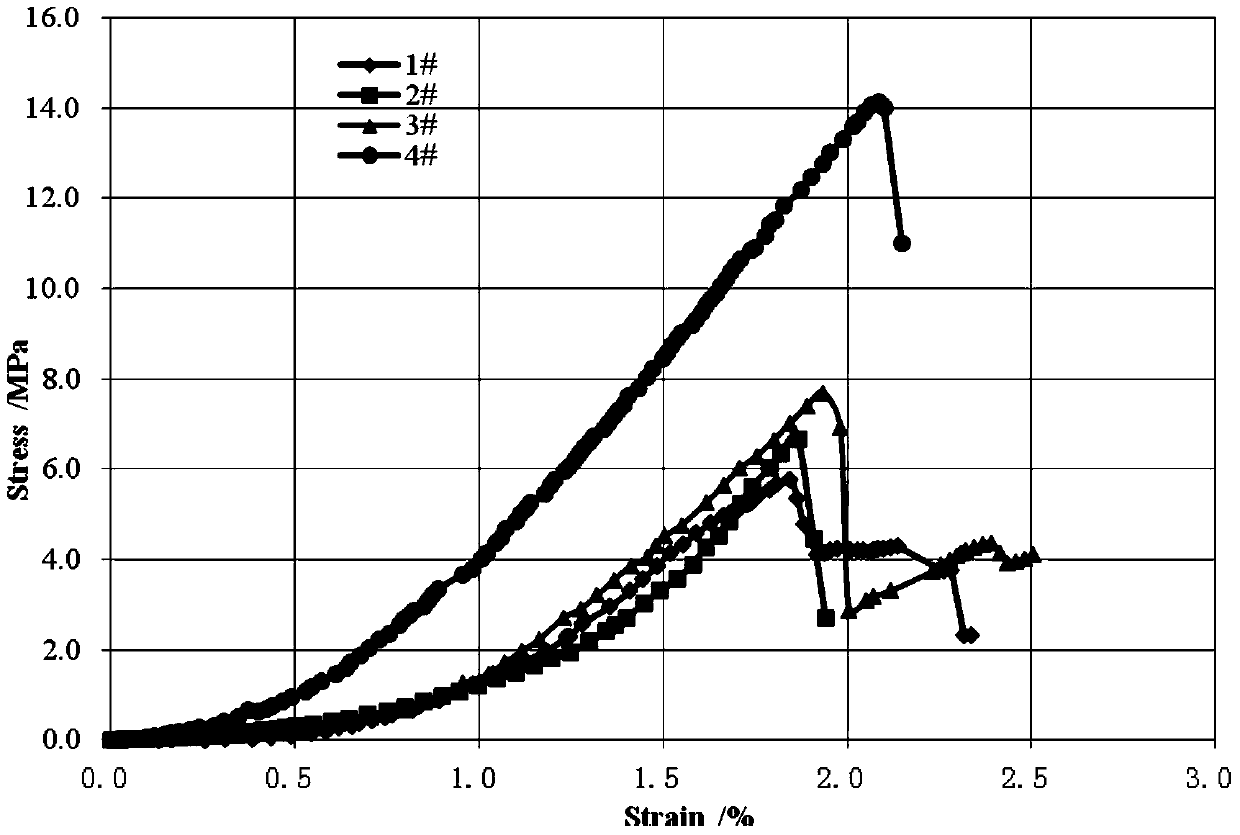

[0041] The unconfined compressive strength test was carried out on the cured coral sand column. Before the test, the surface of the sand column was smoothed, and dried in an oven at 50°C for 48 hours, and then the test was carried out. The stress-strain curve measured by the unconfined compressive strength test is as follows: image 3 As shown, the failure mode is as Figure 4 As shown, the test results are shown in Table 2. It can be seen from Table 2 that the unconfined compressive strength of the solidified coral sand column can reach up to about 14MPa.

[0042] Table 2. Compressive strength of coral sand column samples

[0043] sand column

diameter / cm

Height / cm

Compressive strength / MPa

Way of destruction

1

5.141

8.385

5.76

Fracturing damage

2

5.145

7.763

6.68

Fracturing damage

3

5.115

8.505

7.70

Fracturing damage

4

5.120

8.815

14.14

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com