Transverse alternative heating and vertical coke exhaust coke oven

A technology of alternating heating and coke ovens, applied in the vertical coke discharge type coke oven and the horizontal alternate heating field, can solve the problem that the coke oven production capacity is not effectively released, hinders the material system to use natural gravity to discharge coke, and the energy loss is not fundamental. Solve problems such as increasing the length, height and quantity of the carbonization chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

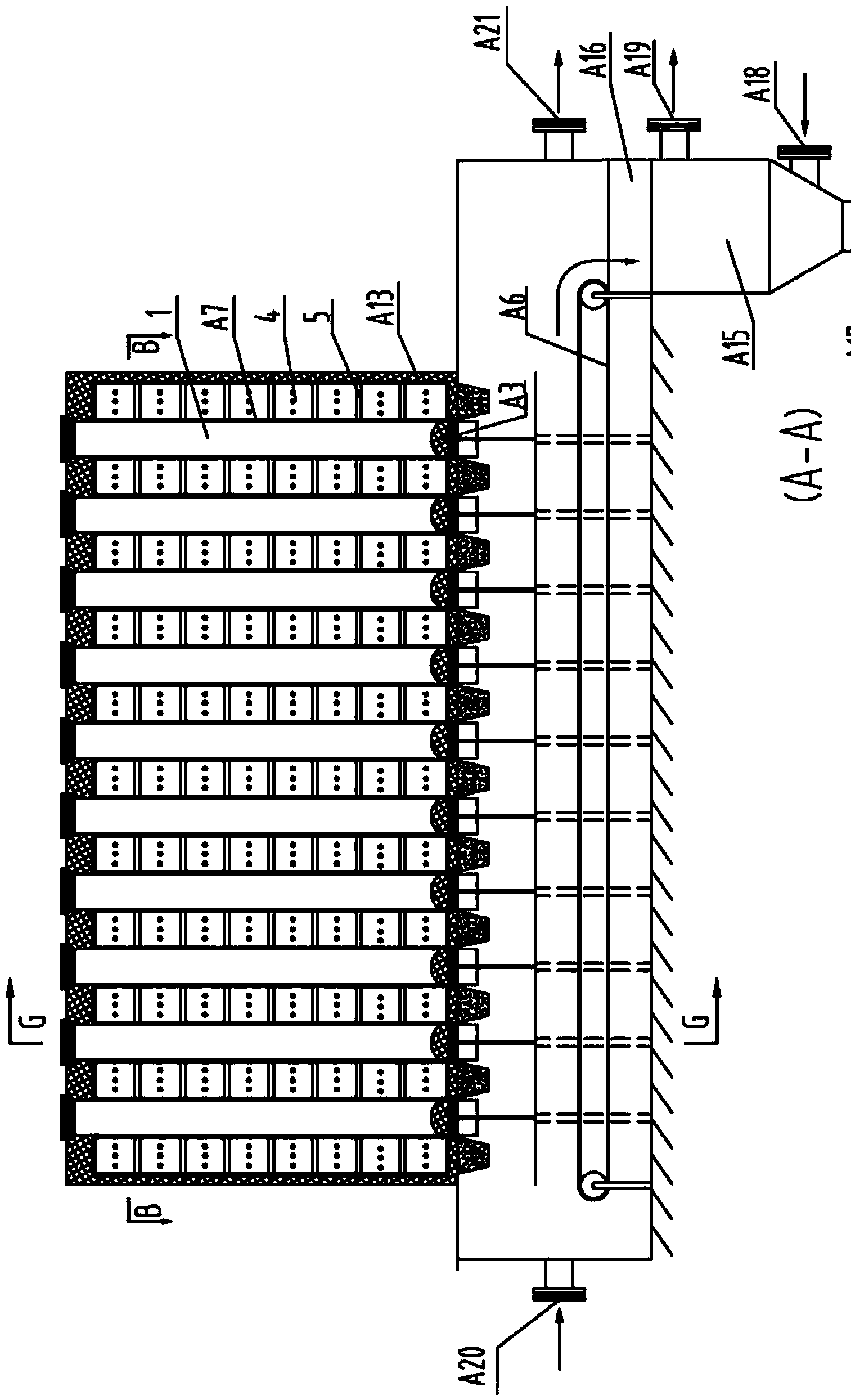

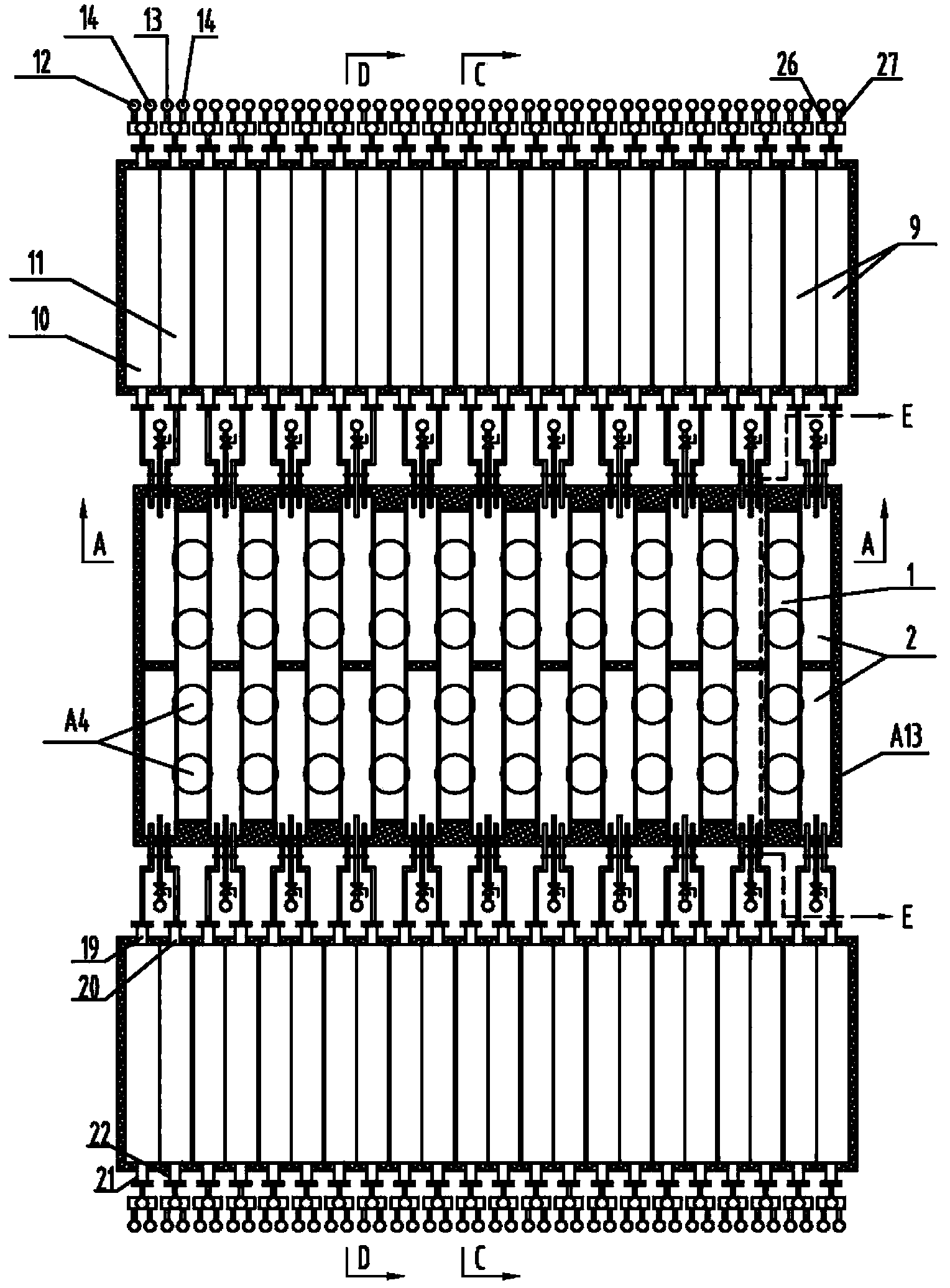

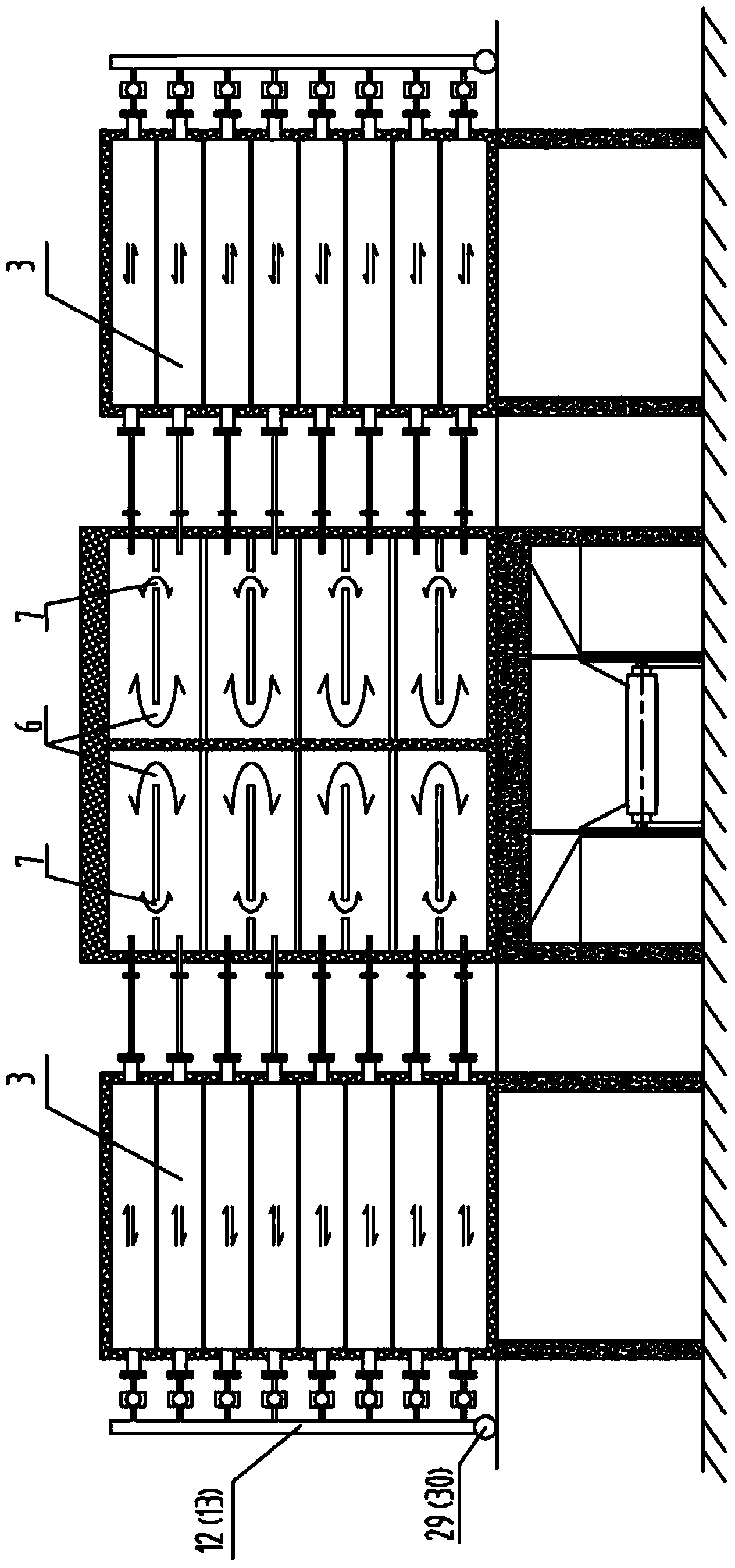

[0046] The present invention is described in detail as follows in conjunction with accompanying drawing:

[0047] Such as Figure 1-7 As shown: horizontal alternate heating, vertical coke discharge type coke oven, including a plurality of carbonization chambers 1 with coal charging holes A2 with hole covers A2 on the top, a plurality of combustion chambers 2, and placed on both sides of each combustion chamber 2 The regenerator 3, the carbonization chamber 1 and the combustion chamber 2 are arranged at intervals, and each carbonization chamber 1 is provided with a combustion chamber 2 at the front and rear;

[0048] It is characterized in that the four sides of the carbonization chamber 1 are all made of silica bricks, and the bottom of the carbonization chamber A1 is provided with an automatic furnace door A3,

[0049] Below the carbonization chamber 1 and the combustion chamber 2, an airtight coke treatment chamber A12 is provided,

[0050] In the coke treatment chamber A12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com