Preparation method of Ag2E nano wire

A nanowire and compound technology, applied in the field of material chemistry, can solve the problems of high reaction temperature, a large amount of organic solvents, and high energy consumption, and achieve the effects of simple process, easy availability of raw materials, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

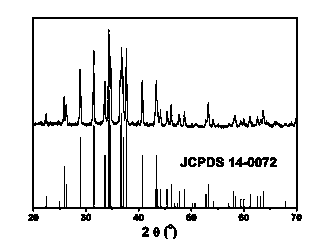

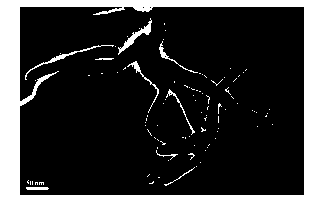

[0022] Synthesis of silver sulfide nanowires at room temperature:

[0023] Add 100ml of deionized water into the beaker, put it into the stirring magnet and stir, weigh 2 mmol of silver nitrate and 2.8g of KOH into the beaker, then weigh 10 mmol of thioglycolic acid into the beaker, and keep stirring until the solution becomes transparent and clear ; then add 1 mmol thioacetamide and 4 mmol b-naphthalenesulfonic acid, stirring continuously; finally add 16 mmol KBH 4 , to be added to all KBH 4 After dissolving, remove the stirring magnet. Seal the mouth of the beaker with plastic wrap to prevent dust from entering, and let it stand at room temperature for 24 hours. The resulting precipitate was washed with deionized water and then centrifuged, and the centrifuged precipitate was redispersed in deionized water, centrifuged again until the pH value of the filtrate was 7, and finally washed with absolute ethanol. The centrifugal sedimentation speed is 3000 rpm. The filtered po...

Embodiment 2、3

[0026] Repeat Example 1, but replace b-naphthalenesulfonic acid with a-naphthalenesulfonic acid and 1,5-dinaphthalenesulfonic acid respectively, to obtain silver sulfide nanowire powder. The yields were 68.4% and 66.7%, respectively.

Embodiment 4

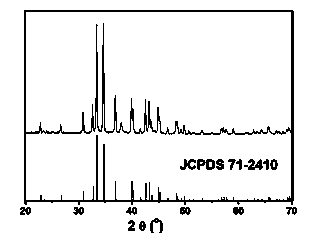

[0028] Synthesis of silver selenide nanowires at room temperature:

[0029] Add 100ml of deionized water into the beaker, put it into the stirring magnet and stir, weigh 2 mmol of silver nitrate and 2g of NaOH into the beaker, then weigh 6 mmol of mercaptopropionic acid into the beaker, and keep stirring until the solution becomes transparent and clear ; then add 1 mmol selenium dioxide and 6 mmol b-naphthalenesulfonic acid, stirring continuously; finally add 12 mmol NaBH 4 , to be added all NaBH 4 After dissolving, remove the stirring magnet. Seal the mouth of the beaker with plastic wrap to prevent dust from entering, and let it stand at room temperature for 24 hours. The resulting precipitate was washed with deionized water and then centrifuged, and the centrifuged precipitate was redispersed in deionized water, centrifuged again until the pH value of the filtrate was 7, and finally washed with absolute ethanol. The centrifugal sedimentation speed is 3000 rpm. The f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com