Microelectronic mechanical dual channel microwave power detection system and preparation method thereof

A micro-electromechanical and microwave power technology, which is used in electrical power measurement by thermal method, components of TV systems, generators/motors, etc., can solve problems such as small signal amplitude, increase area, improve sensitivity, and facilitate integration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

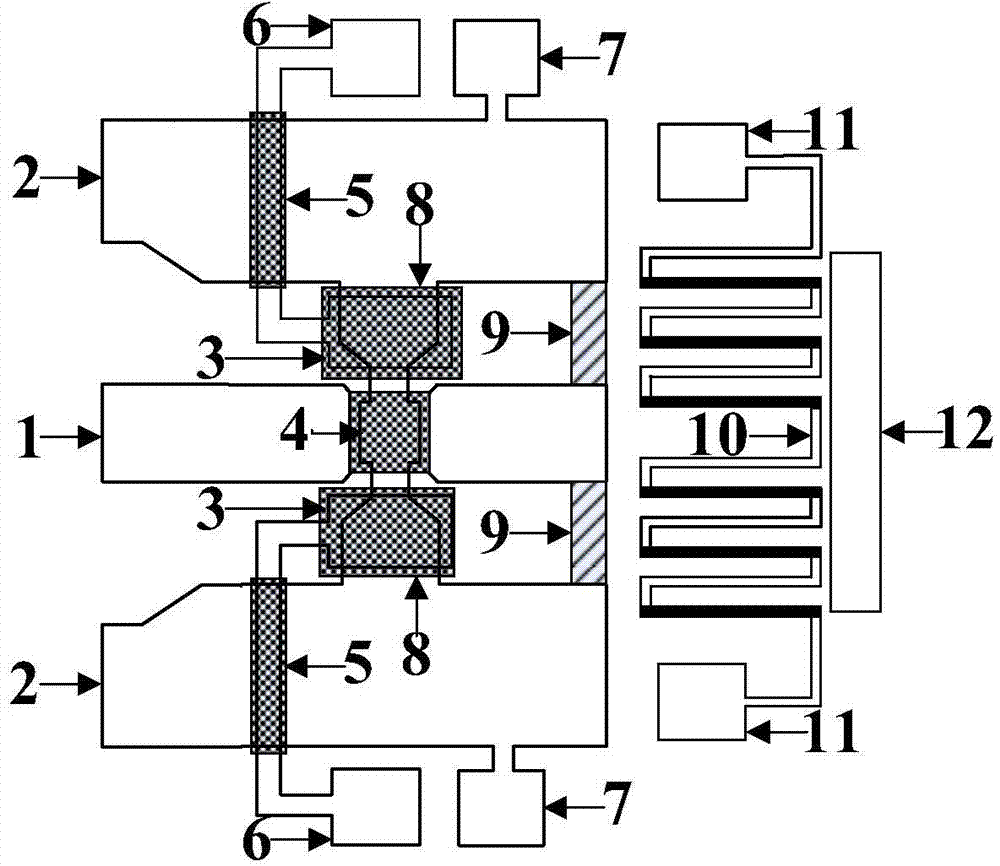

[0029] The invention will be described in further detail below in conjunction with the accompanying drawings.

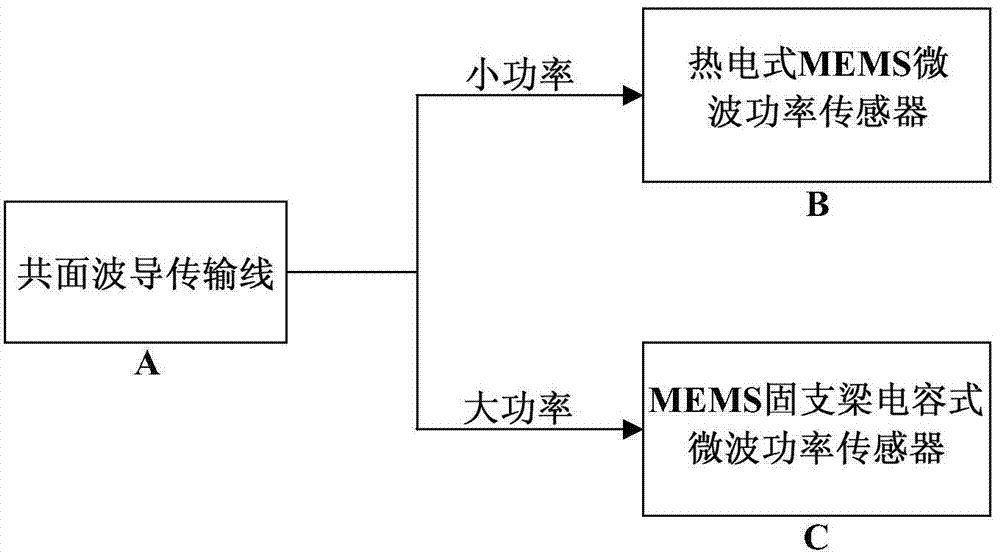

[0030] Such as figure 1 As shown, when the microwave power to be measured is small, the MEMS fixed support beam cannot be pulled down, and is connected to the thermoelectric MEMS microwave power sensor through the coplanar waveguide transmission line, and the microwave power to be measured is detected by the thermoelectric MEMS microwave power sensor; when the microwave power to be measured When it is larger, the MEMS fixed beam is pulled down and connected to the MEMS fixed beam capacitive microwave power sensor through the coplanar waveguide transmission line, and the microwave power to be measured is detected by the MEMS fixed beam capacitive microwave power sensor. Using these two detection methods can not only expand the range of microwave signal detection, but also when the microwave signal is too large, the MEMS fixed-beam capacitive microwave power sensor can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com