Novel insulated special cable and preparation method thereof

A special cable, a new type of technology, applied in the direction of insulated cables, cable/conductor manufacturing, insulated conductors, etc., can solve the problems of large specific gravity, intolerance to hydrolysis and radiation, fluorine-containing toxicity, etc., achieve light specific gravity, oxygen index 33, The effect of heat resistance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

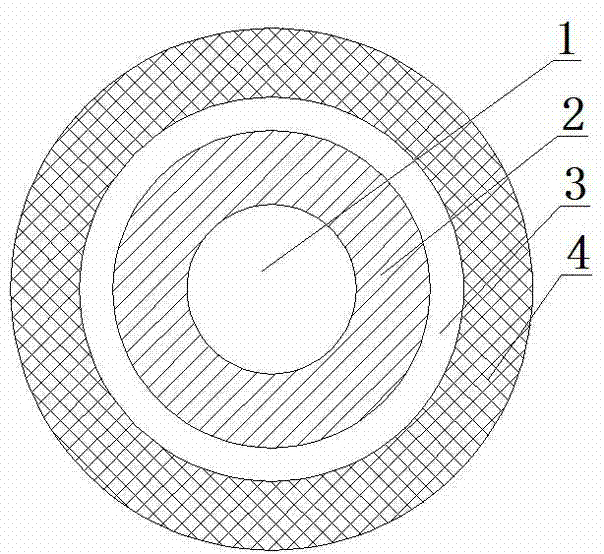

[0019] like figure 1 As shown, the insulated special cable includes a conductor 1, which is nickel-plated outside the conductor 1, and is characterized in that: the nickel-plated conductor 1 is covered with a PPEK insulating layer 2; the PPEK insulating layer 2 is wrapped with a fireproof layer 3; the fireproof layer 3 The outer braid has a wear-resistant layer 4;

[0020] The PPEK insulating layer 2 is an insulating layer whose polymer material is heterocyclic biphenyl polyether ketone.

[0021] The specific preparation method steps of the insulated special cable are as follows:

[0022] a. Use high-quality oxygen-free copper TU as the conductor, and nickel-plated after stretching;

[0023] b. PPEK thermoplastic resin, in granular form, is in a molten state through an extruder at 350°C, and is continuously extruded on the nickel-plated wire under the forming mold and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com