Large-scale preparation method for graphene quantum dots

A large-scale preparation technology of graphene quantum dots, applied in the direction of graphene, chemical instruments and methods, luminescent materials, etc., can solve the problems of complex steps, complex processes, low yield, etc., achieve large reaction volume, simple process, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

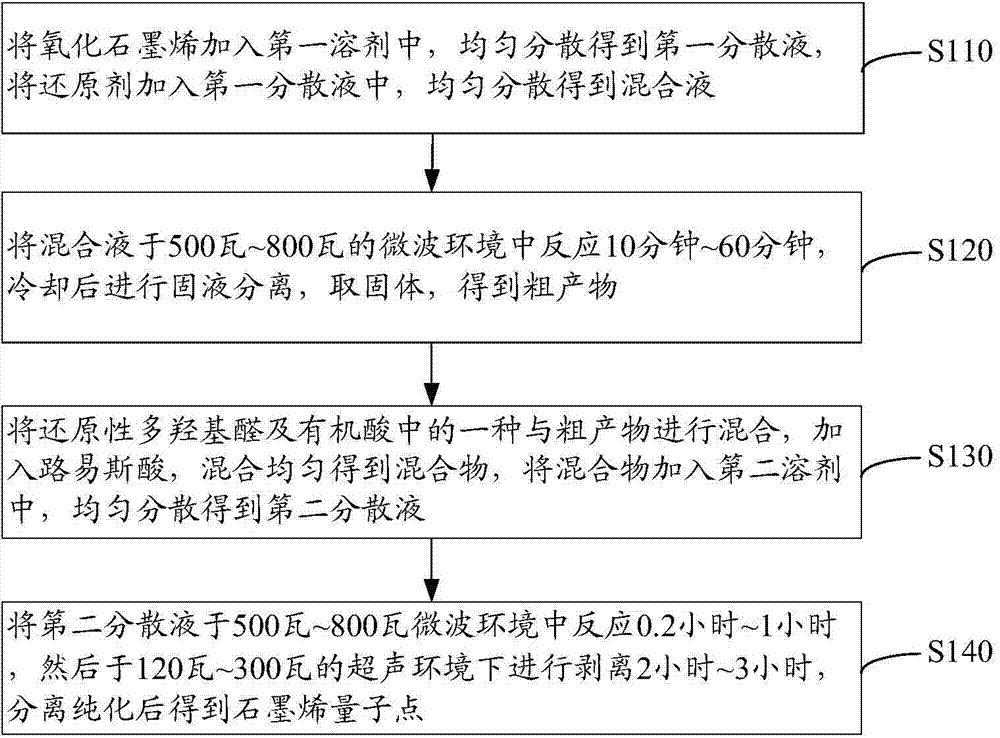

[0033] see figure 1 , a method for large-scale preparation of graphene quantum dots in an embodiment, comprising the following steps S110 to S140.

[0034] Step S110: adding graphene oxide into the first solvent, uniformly dispersing to obtain a first dispersion liquid, adding a reducing agent to the first dispersion liquid, and uniformly dispersing to obtain a mixed liquid.

[0035] Graphene oxide is preferably monolayer graphene oxide prepared by a modified Hummers' chemical method.

[0036] The first solvent is at least one selected from water, dimethoxyethane, polyvinyl alcohol aqueous solution, glycerol, diethylene glycol and N-methylpyrrolidone. The boiling points of these solvents are relatively high, and the high-boiling-point solvents can provide a sufficiently high ambient temperature for the deoxygenation and reduction of graphene oxide, and the above-mentioned high-boiling-point solvents have no adverse reaction with graphene oxide.

[0037] Preferably, the first...

Embodiment 1

[0079] Preparation of graphene quantum dots

[0080] 1. Provide single-layer graphene oxide prepared by improving Hummers' chemical method, disperse single-layer graphene oxide in dimethoxyethane, and uniformly disperse to obtain the first monolayer graphene oxide concentration of 2mg / mL Dispersion liquid, adding oxalic acid to the first dispersion liquid, uniformly dispersed to obtain a mixed liquid; wherein, the mass ratio of single-layer graphene oxide to oxalic acid is 1:3;

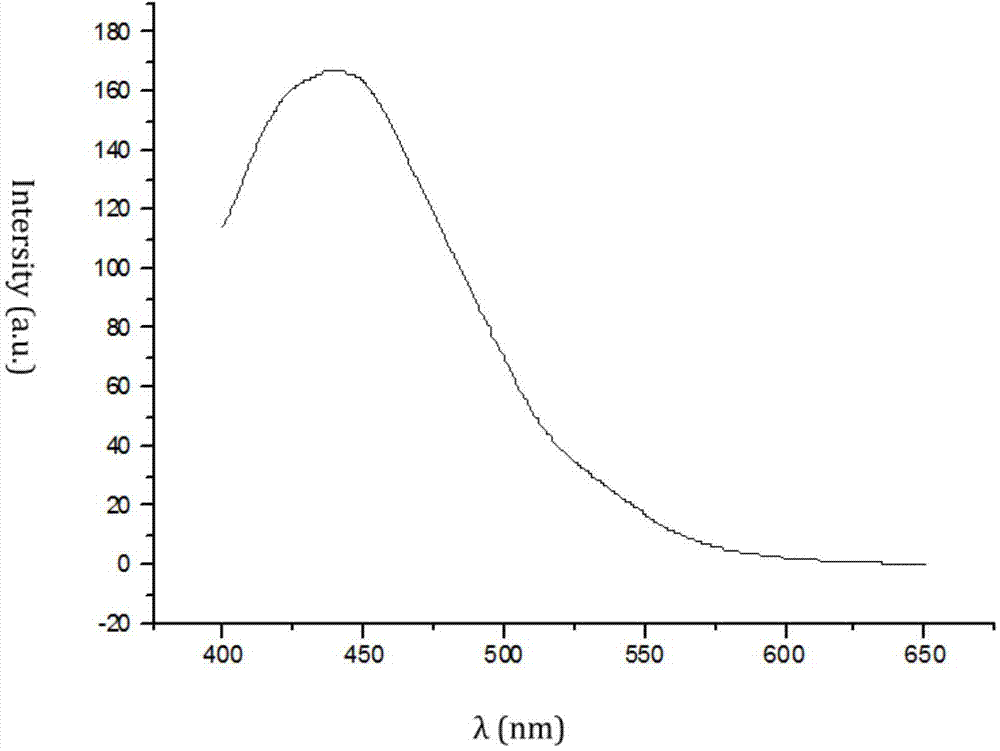

[0081]2. The mixture was ultrasonically dispersed in a 120W ultrasonic environment for 4 hours, then placed in a closed reaction container, and reacted in a 500W microwave environment for 30 minutes; take out and add dimethoxyethane, and the added dimethoxy The volume of ethane is 15% of the volume of the initial dimethoxyethane in the first dispersion liquid; continue to react in the microwave environment of 500W for 10min, after the reaction finishes, wait for the reaction liquid to cool down, add t...

Embodiment 2

[0086] Preparation of graphene quantum dots

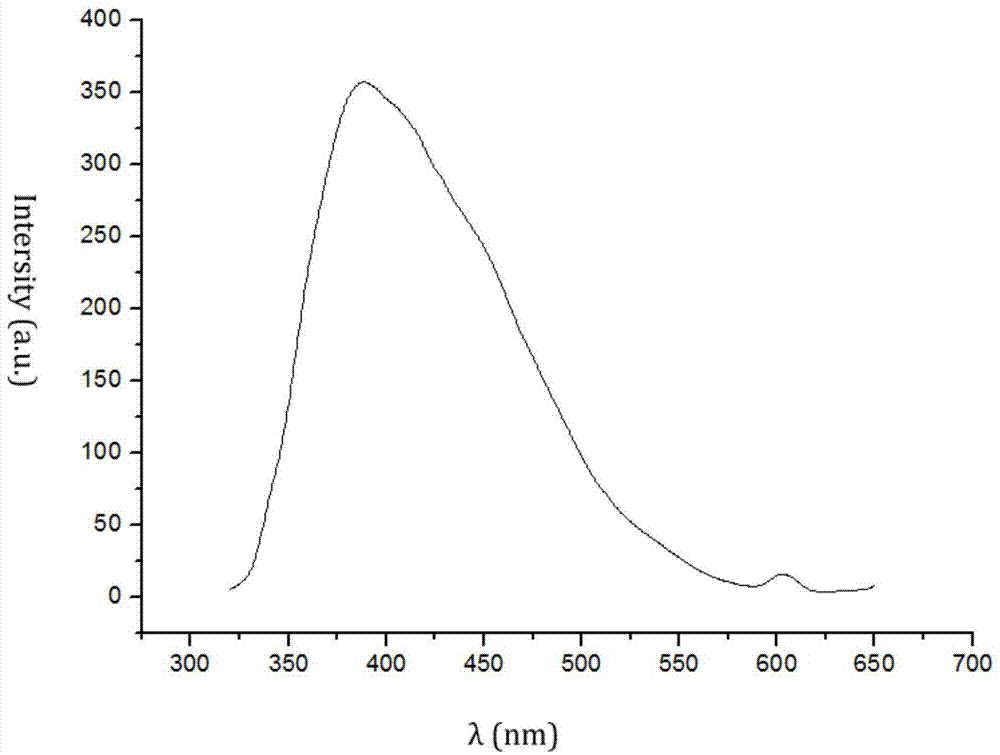

[0087] 1. Provide single-layer graphene oxide prepared by improving Hummers’ chemical method, disperse single-layer graphene oxide in a mixed solvent of triethylene glycol and N-methylpyrrolidone with a volume ratio of 1:1, and disperse evenly Obtaining the concentration of monolayer graphene oxide is the first dispersion liquid of 6mg / mL, sodium oxalate is added in the first dispersion liquid, evenly dispersed to obtain mixed solution; Wherein, the mass ratio of monolayer graphene oxide and sodium oxalate is 1: 8;

[0088] 2. Ultrasonically disperse the mixed solution for 1 hour in a 150W ultrasonic environment, put it into a closed reaction container, and react in a 700W microwave environment for 20 minutes; take out and add diethylene glycol and N at a volume ratio of 1:1 -The mixed solvent of methylpyrrolidone, the volume ratio of the mixed solvent of diethylene glycol and N-methylpyrrolidone added is that the volume ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Emission wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com