Method for preparing sintered bricks from pressure filtration residues

A technology for filter press residue and sintered bricks, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as the ineffective utilization of filter press residues, eliminate secondary pollution, enhance strength, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

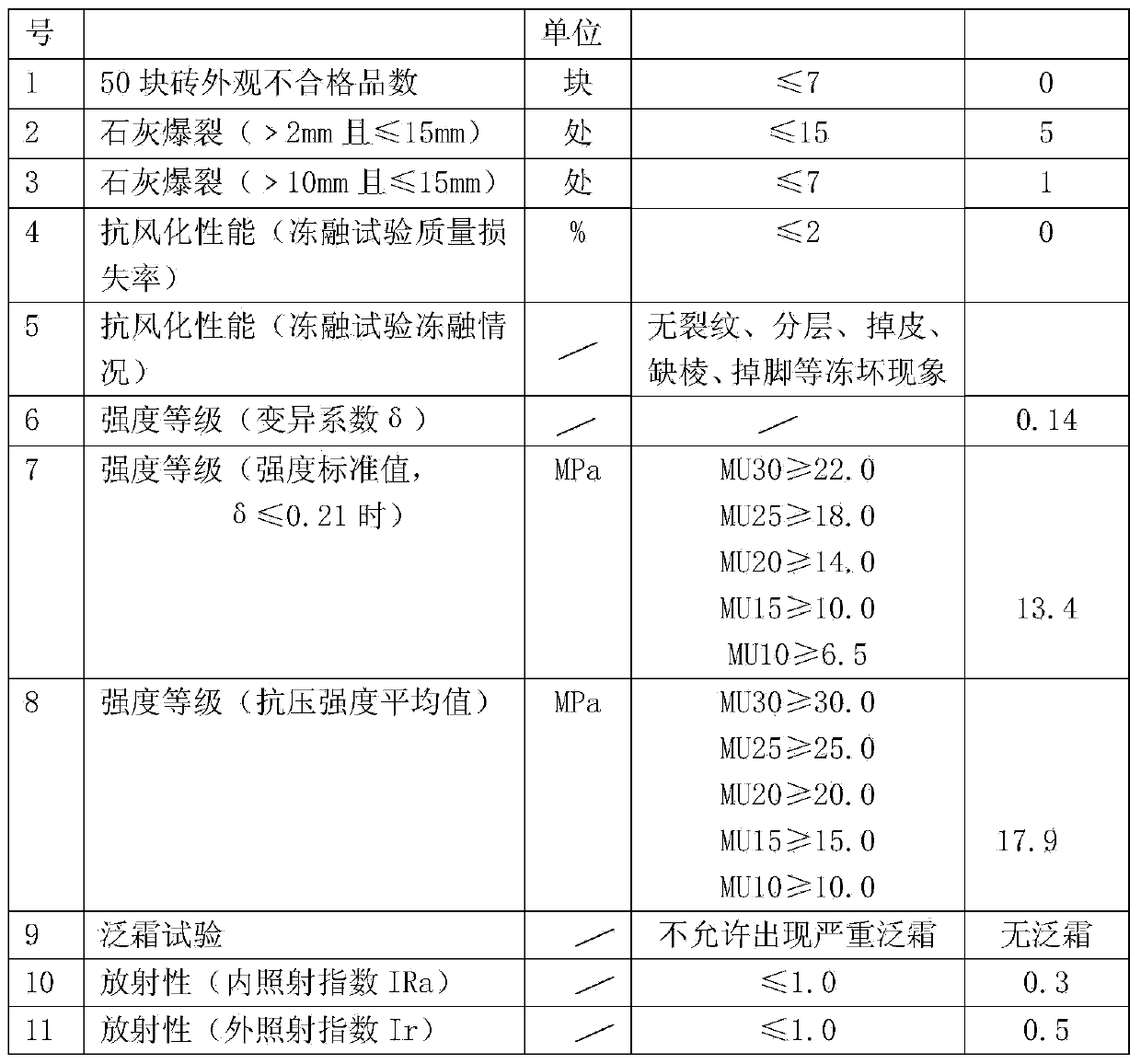

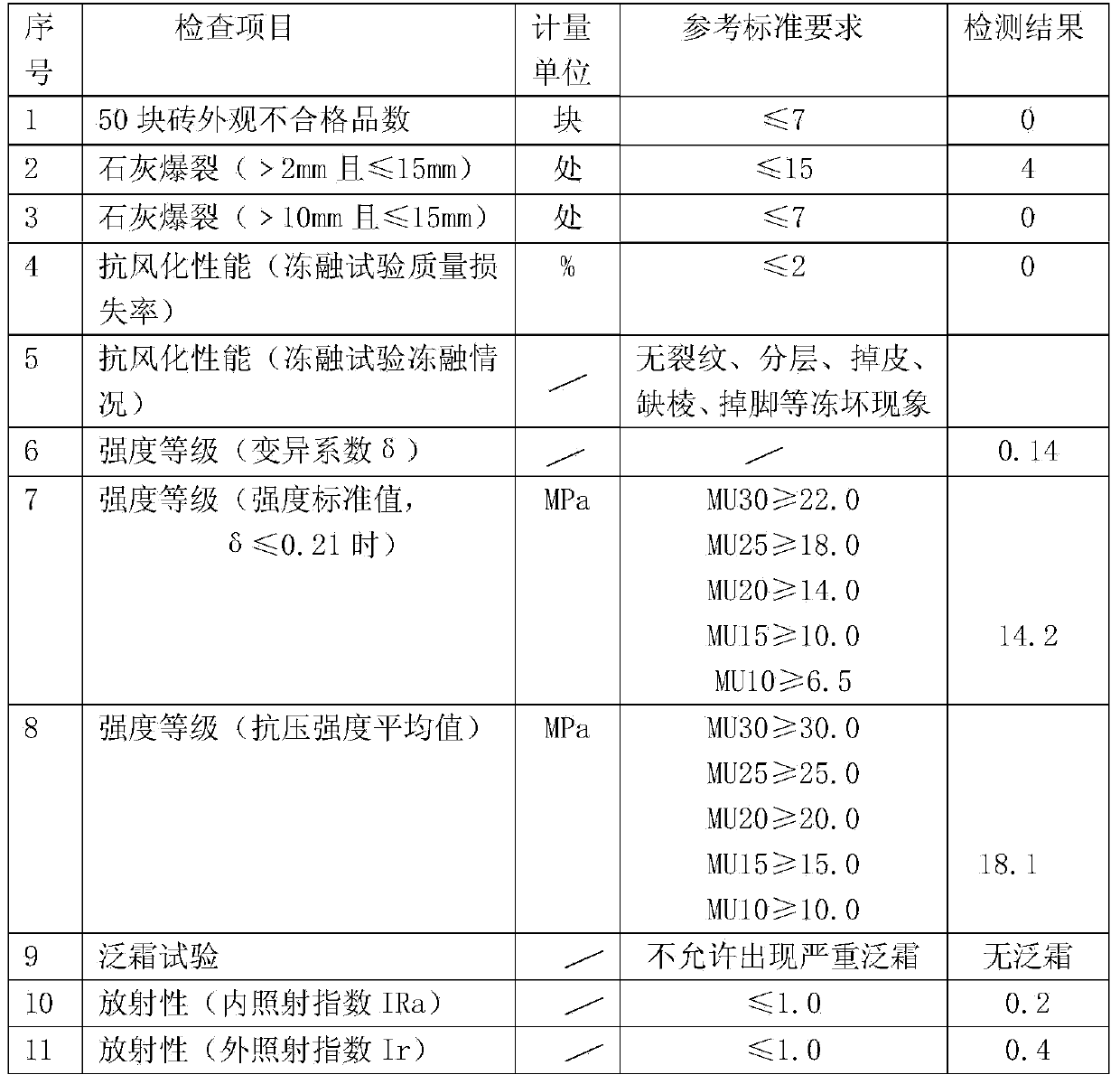

Embodiment 1

[0022] During the electrolysis of manganese dioxide, manganese carbonate ore is used for leaching and liquid preparation, and the press filter residue produced by crushing and water is directly transported to the soaking and mixing tank according to the solid-liquid ratio of 1:2. Crush the bauxite tailings and coal gangue to 60 mesh respectively, mix evenly according to the ratio of bauxite tailings and coal gangue = 75:25, and set aside. Press the filter residue into the immersion mixing tank: barium carbonate=100:0.5, add barium carbonate, stir and soak for 24 hours. Use 15% ammonium bicarbonate aqueous solution to adjust the pH value to 8, stir for 1 hour, pump into a filter press for solid-liquid separation, and set aside the solid residue. (The liquid is transported to the evaporation concentrator to control the distillate volume ratio; mixed concentrated liquid: distilled water = 2:8. The water returns to soak the press filter residue, and the concentrated liquid contain...

Embodiment 2

[0027] When manganese metal is electrolyzed, manganese oxide ore is used for leaching and liquid preparation, and the press filter residue produced by crushing and water is directly transported to the soaking and mixing tank according to the solid-liquid ratio of 1:2. Crush the bauxite tailings and coal to 60 mesh respectively, mix them evenly according to the ratio of bauxite tailings: coal = 85:15, and set aside. Add barium carbonate to the immersion and mixing tank by pressing filter residue in proportion: barium carbonate = 100:1, stir and soak for 24 hours. Use 15% ammonium bicarbonate aqueous solution to adjust the pH value to 8, stir for 1 hour and pump into a filter press for solid-liquid separation, and the solid residue is set aside. (The liquid is transported to the evaporation concentrator to control the distillate volume ratio; mixed concentrated liquid: distilled water = 2:8. The water returns to soak the press filter residue, and the concentrated liquid containi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com