Method of preparing metal organic frame compound by using ultrasonic waves

A metal-organic framework and compound technology, which is applied in the preparation of organic compounds, zinc organic compounds, and 2/12 group organic compounds without C-metal bonds, etc., to achieve mild reaction conditions, lower reaction temperature, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

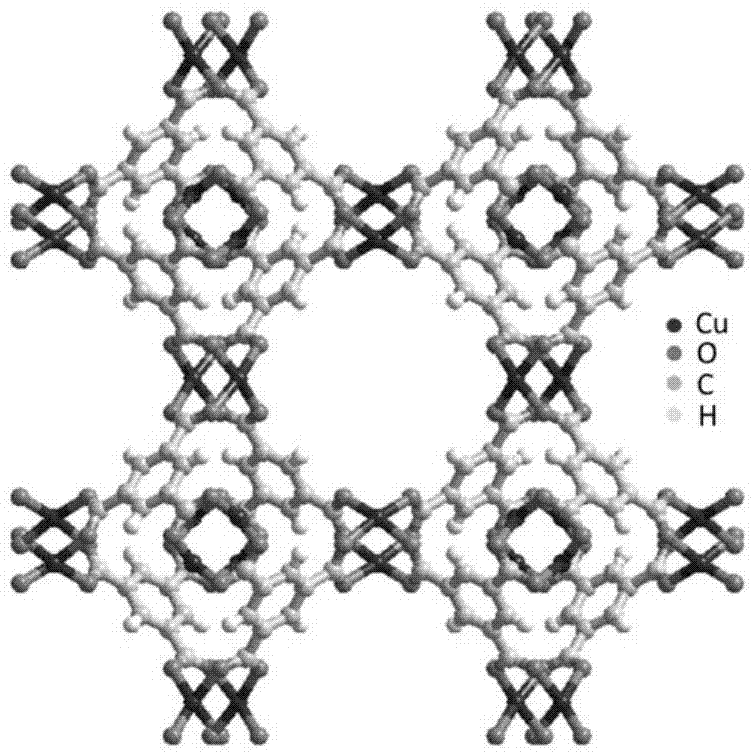

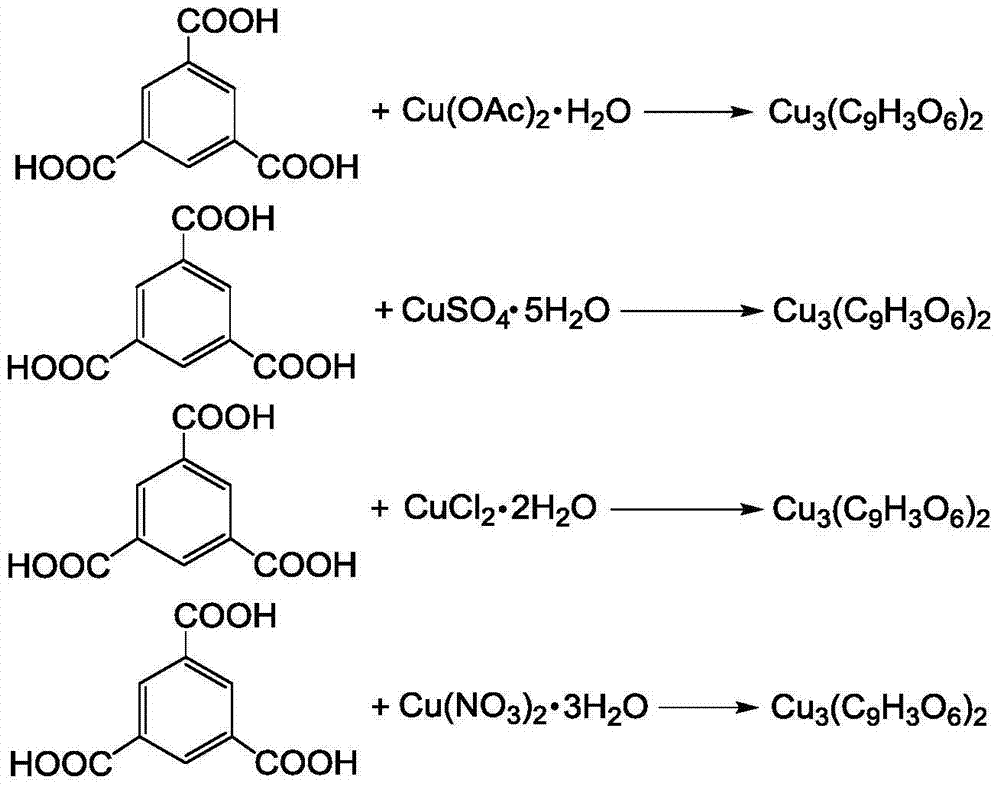

[0028] Copper acetate provided metal ions to synthesize metal organic framework compound MOF-199.

[0029] Under ultrasonication, copper acetate monohydrate (1.72g, 8.62mmol) was dissolved in a mixed solvent of water (16mL) and DMF (8mL), trimesic acid (1.00g, 4.76mmol) was dissolved in ethanol (16mL) and In the mixed solvent of DMF (8mL), mix the two solutions, stir for 10min, add triethylamine (1.0mL), stir evenly, and intermittently sonicate at the ultrasonic frequency of 400-800W for 30min (ultrasound for 2s, stop for 3s) , The reaction temperature is 20°C to 50°C. After suction filtration, the obtained product was replaced twice with water, three times with DMF, and soaked in a certain amount of DMF for 12 hours; suction filtered, replaced with dichloromethane three times, and the product was soaked in dichloromethane for 12 hours; The sample was dried under vacuum for 24 hours to obtain the metal organic framework compound MOF-199 (1.43 g, yield 99.1%).

[0030] The pr...

Embodiment 2

[0032] Copper sulfate provided metal ions to synthesize metal organic framework compound MOF-199.

[0033] Dissolve copper sulfate pentahydrate (2.12g, 8.48mmol) in a mixed solvent of water, DMF and ethanol (24mL, the volume ratio of water, DMF and ethanol is 1:1:1) under the action of ultrasonic waves, trimesic acid (1.00mg, 4.76mmol) was dissolved in the same mixed solvent (20mL, the volume ratio of water, DMF, and ethanol was 1:1:1), after mixing the two solutions, add triethylamine (0.8mL), stir Evenly, continue to intermittently sonicate at a frequency of 400-800W for 20min (set the ultrasonic conditions, sonicate for 2s, stop for 3s), and the reaction temperature is 20°C-50°C. After suction filtration, the obtained product was replaced twice with water, three times with DMF, and soaked in a certain amount of DMF for 12 hours; suction filtered, replaced with dichloromethane three times, and the product was soaked in dichloromethane for 12 hours; The sample was dried unde...

Embodiment 3

[0036] Copper chloride provided metal ions to synthesize metal organic framework compound MOF-199.

[0037] Copper chloride dihydrate (1.44g, 8.45mmol) was dissolved in a mixed solvent of water (16mL) and DMF (8mL), trimesic acid (1.00g, 4.76mmol) was dissolved in ethanol (16mL) and DMF (8mL ) in a mixed solvent, mix the two solutions, stir for 1min, add triethylamine (1.0mL), stir evenly, and intermittently sonicate at an ultrasonic frequency of 100-400W for 60min (ultrasound for 3s, stop for 2s), the reaction temperature 20℃~50℃. After suction filtration, the obtained product was replaced twice with water, three times with DMF, and soaked in a certain amount of DMF for 12 hours; suction filtered, replaced with dichloromethane three times, and the product was soaked in dichloromethane for 12 hours; The sample was dried under vacuum for 24 hours to obtain a relatively pure MOF-199 metal organic framework (1.35 g, yield 93.6%).

[0038]The prepared samples were analyzed by po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com