Method for preparing europium-doped hydroxyapatite nanorod

A hydroxyapatite and nanorod technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve harsh conditions, complex preparation process of europium-doped hydroxyapatite, material crystallinity, fluorescence intensity and dispersion. It is difficult to achieve good uniformity and other problems, so as to achieve the effects of low equipment requirements, good dispersion and luminescence performance, and controllable morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 1.7597g of europium oxide, then add 30ml of dilute nitric acid with a concentration of 4mol / L, stir for 30 minutes under heating conditions, and after completely dissolving, prepare a 0.2mol / L europium nitrate solution.

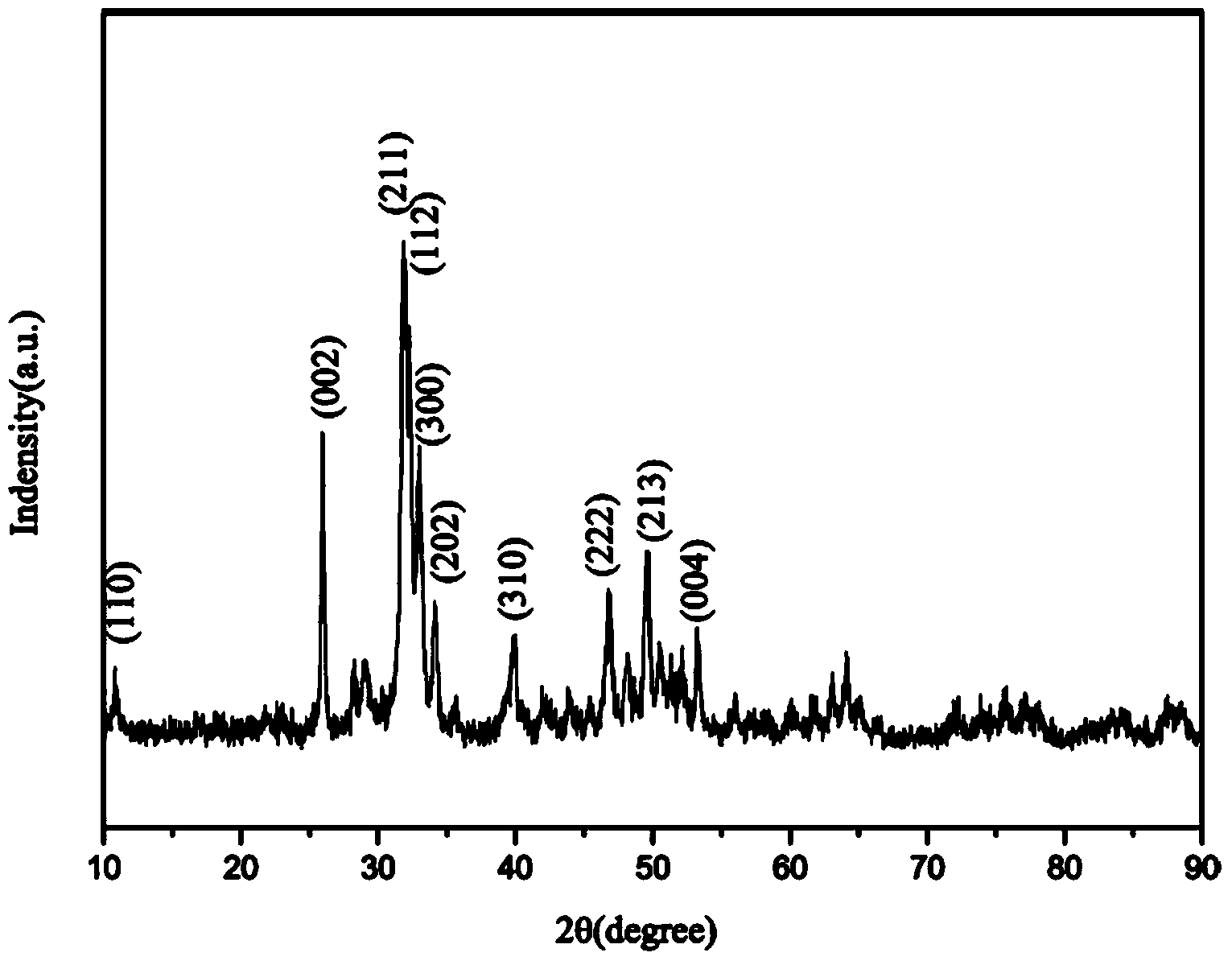

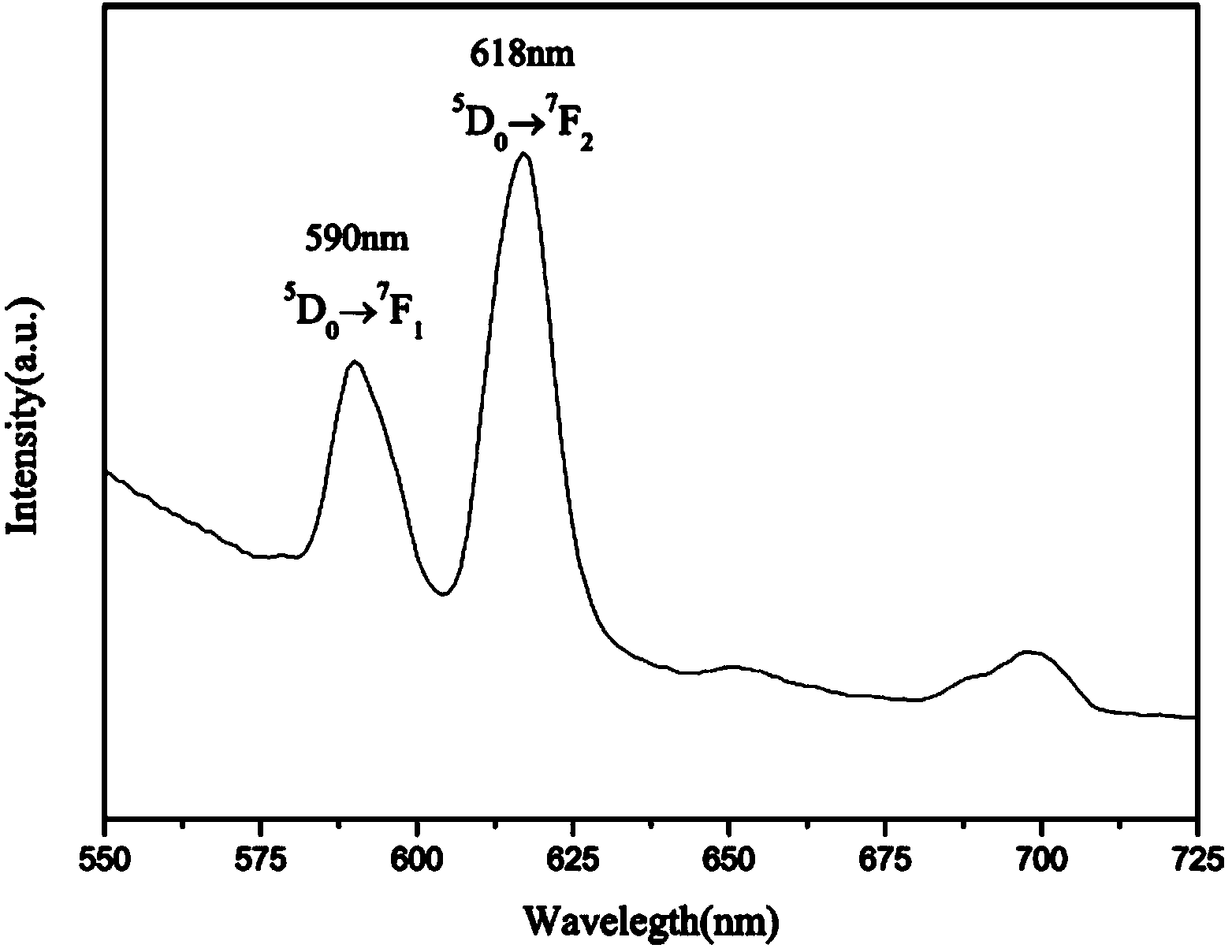

[0019] Weigh 1.584g of diammonium hydrogen phosphate and 1g of cetyltrimethylammonium bromide into the beaker, measure 50ml of distilled water into the beaker and dissolve, adjust the pH value to 12 with 1mol / L NaOH solution , is solution 1. Weigh 2.109g of anhydrous calcium chloride and add it to another beaker, add 25ml of distilled water to dissolve it, and use a pipette to measure 5ml of the prepared europium nitrate solution and add it to the beaker, which is solution 2. Then the solution 2 was slowly added dropwise to the continuously stirring solution 1, the mixed solution was heated to 100° C., and reacted for 6 hours. After the reaction was completed, the suspension was left to stand for 3 hours, and then the precipitate was washed 8 ti...

Embodiment 2

[0024] Weigh 1.7597g of europium oxide, then add 30ml of dilute nitric acid with a concentration of 4mol / L, stir for 30 minutes under heating conditions, and after completely dissolving, prepare a 0.2mol / L europium nitrate solution.

[0025] Weigh 1.584g of diammonium hydrogen phosphate and 1g of cetyltrimethylammonium bromide into the beaker, measure 50ml of distilled water into the beaker and dissolve, adjust the pH value to 12 with 1mol / L NaOH solution , is solution 1. Weigh 2.198g of anhydrous calcium chloride and add it to another beaker, add 25ml of distilled water to dissolve it, take 1ml of the prepared europium nitrate solution with a pipette and add it to the beaker, which is solution 2. Then the solution 2 was slowly added dropwise to the continuously stirring solution 1, the mixed solution was heated to 100° C., and reacted for 6 hours. After the reaction was completed, the suspension was left to stand for 3 hours, and then the precipitate was washed 5 times with ...

Embodiment 3

[0027] Weigh 1.7597g of europium oxide, then add 30ml of dilute nitric acid with a concentration of 4mol / L, stir for 30 minutes under heating conditions, and after completely dissolving, prepare a 0.2mol / L europium nitrate solution.

[0028] Weigh 1.584g of diammonium hydrogen phosphate and 1g of cetyltrimethylammonium bromide into the beaker, measure 50ml of distilled water into the beaker and dissolve, adjust the pH value to 12 with 1mol / L NaOH solution , is solution 1. Weigh 1.998g of anhydrous calcium chloride and add it to another beaker, add 25ml of distilled water to dissolve it, and use a pipette to measure 10ml of the prepared europium nitrate solution and add it to the beaker to form solution 2. Then the solution 2 was slowly added dropwise to the continuously stirring solution 1, the mixed solution was heated to 100° C., and reacted for 6 hours. After the reaction was completed, the suspension was left to stand for 3 hours, and then the precipitate was washed 10 ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com