Method for enriching noble metals from high-sulfur material

A technology for precious metals and materials, which is applied in the enrichment of low-grade precious metals and the enrichment of precious metals from high-sulfur materials. It can solve the problems of increasing the complexity of the enrichment process and achieve high recovery rate of precious metals, high enrichment ratio and easy investment. The effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

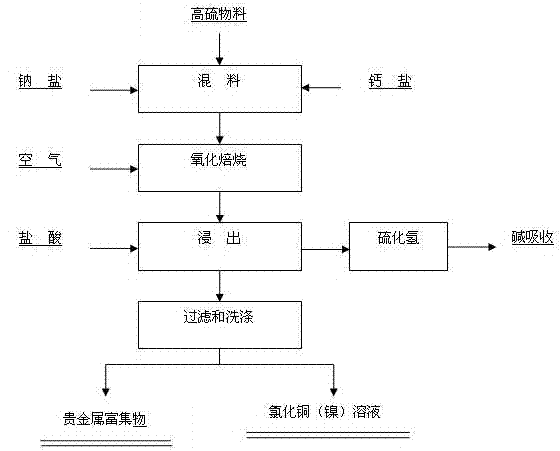

[0027] Example 1, refer to the accompanying drawings, weigh 10kg of high-sulfur materials (containing Ni12.01%, Cu2.27%, S52.1%, Au60.87g / t, Ag120.11g / t, Pt101.23g / t, Pd92 .78g / t), add sodium carbonate as 20% by weight of high-sulfur material, lime as 10% by weight of high-sulfur material, mix and grind in a ball mill for 1 hour, after mixing, put it in a rotary kiln for oxidative roasting to fix sulfur, The roasting time is 3 hours, the roasting temperature is 700°C; after the roasting, hydrochloric acid is used for leaching, the concentration of hydrochloric acid is 25%, the volume is 50L, the leaching time is 4 hours, and the leaching temperature is 70°C; sodium salt and lime are added to the leaching solution, and the weight is 12kg. After filtering and washing, the precious metal enrichment is obtained, the precious metal enrichment ratio reaches 15.21 times, the precious metal content in the leach solution is less than 0.0004g / L, the precious metal yield is greater than 9...

Embodiment 2

[0028] Example 2, refer to the accompanying drawings, weigh 15kg of high-sulfur materials (containing Ni12.01%, Cu2.27%, S52.1%, Au60.87g / t, Ag120.11g / t, Pt101.23g / t, Pd92 .78g / t), add sodium hydroxide to the weight ratio of high-sulfur material 25%, calcium sulfate to the weight ratio of high-sulfur material 20%, mix and grind in a ball mill for 2 hours, after mixing, put it in a rotary kiln for oxidation roasting and solidification Sulfur, roasting time 6h, roasting temperature 800°C; leaching with hydrochloric acid after roasting, hydrochloric acid concentration 30%, leaching time 4h, leaching temperature 85°C, liquid-solid ratio 6:1; add sodium salt and lime to the leached liquid , the weight is 15kg, after filtering and washing, the precious metal enrichment is obtained, the precious metal enrichment multiple reaches 15.87 times, the precious metal content in the leach solution is <0.0005g / L, the precious metal yield is greater than 99.3%, and the precious metal is not dis...

Embodiment 3

[0029] Example 3, referring to the accompanying drawings, weighed 25kg of high-sulfur materials (containing Ni12.01%, Cu2.27%, S52.1%, Au60.87g / t, Ag120.11g / t, Pt101.23g / t, Pd92 .78g / t), add sodium sulfate to the weight ratio of high-sulfur material 24%, calcium hydroxide to the weight ratio of high-sulfur material 15%, mix and grind in the ball mill for 3 hours, after mixing, put it in the rotary kiln for oxidative roasting and solidification Sulfur, roasting time 5h, roasting temperature 750°C; leaching with hydrochloric acid after roasting, hydrochloric acid concentration 15%, leaching time 5h, leaching temperature 75°C, liquid-solid ratio 7:1; add sodium salt and lime to the leached liquid , the weight is 18kg, after filtering and washing, the precious metal enrichment is obtained, the precious metal enrichment multiple reaches 16.01 times, the precious metal content in the leach solution is <0.0005g / L, the precious metal yield is greater than 99.2%, and the precious metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com