A kind of industrialized preparation method of wc-12co cemented carbide with ultrahigh bending strength

A technology of bending strength and cemented carbide, which is applied in the field of cemented carbide, can solve problems such as the difficulty in preparing cemented carbide bulk materials, reduce the probability of micro-crack nucleation and expansion, and achieve high precision of composition control. The effect of reducing the influence of flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

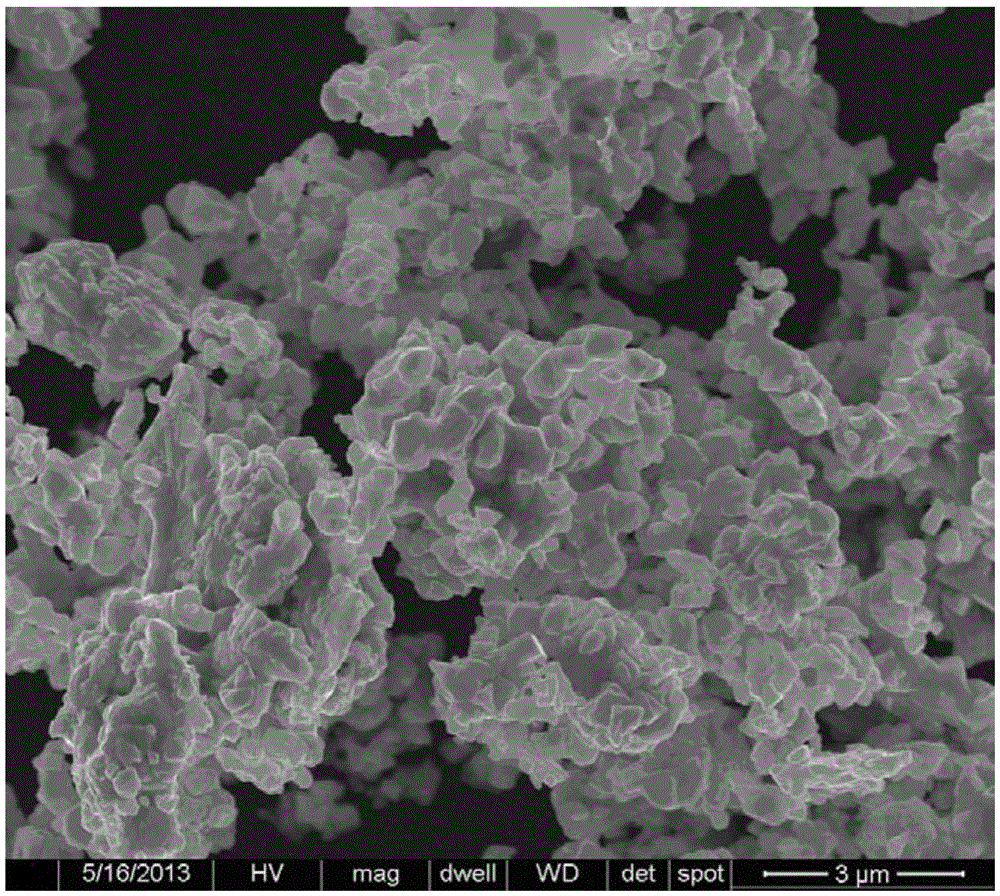

[0020] with WO 2.9 、Co 3 o 4 and carbon black as raw materials, according to the relationship between the composition of the cemented carbide and the relative magnetic saturation value, the carbon content in the raw material powder is regulated, so that the relative magnetic saturation value of the prepared cemented carbide bulk material is 83%, The above three raw material powders are mixed by ball milling, and the mixed powder is cold-pressed into a compact and sent to a vacuum furnace. The following process parameters are used to prepare WC-12Co composite powder in the vacuum furnace: heating rate 4°C / min, reaction temperature 950°C , the holding time is 3 hours;

[0021] For Cr with micron particle size 3 C 2 The powder is pretreated by ball milling, using absolute ethanol as the grinding medium, the mass ratio of the grinding ball to the powder is 3:1, the volume ratio of the grinding medium to the material is 1:1, and the ball milling time is 100 hours;

[0022] The...

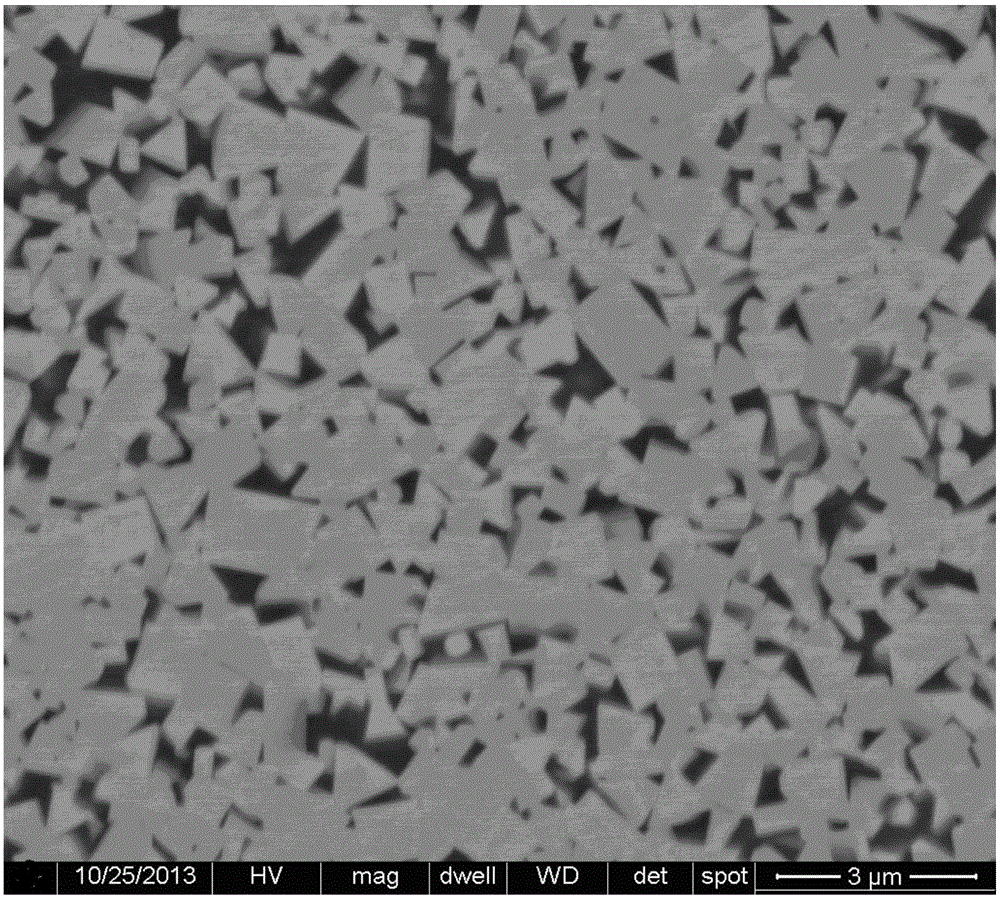

Embodiment 2

[0026] with WO 2.9 、Co 3 o 4 and carbon black as raw materials, the carbon content in the raw material powder is regulated according to the relationship between the composition of the cemented carbide and the relative magnetic saturation value, so that the relative magnetic saturation value of the prepared cemented carbide bulk material is 85%, The above three raw material powders are mixed by ball milling, and the mixed powder is cold-pressed into a compact and sent to a vacuum furnace. The following process parameters are used to prepare WC-12Co composite powder in the vacuum furnace: heating rate 10°C / min, reaction temperature 1100°C , the holding time is 2 hours;

[0027] For Cr with micron particle size 3 C 2 The powder is pretreated by ball milling, using absolute ethanol as the grinding medium, the mass ratio of the grinding ball to the powder is 5:1, the volume ratio of the grinding medium to the material is 1:1, and the ball milling time is 80 hours;

[0028] The...

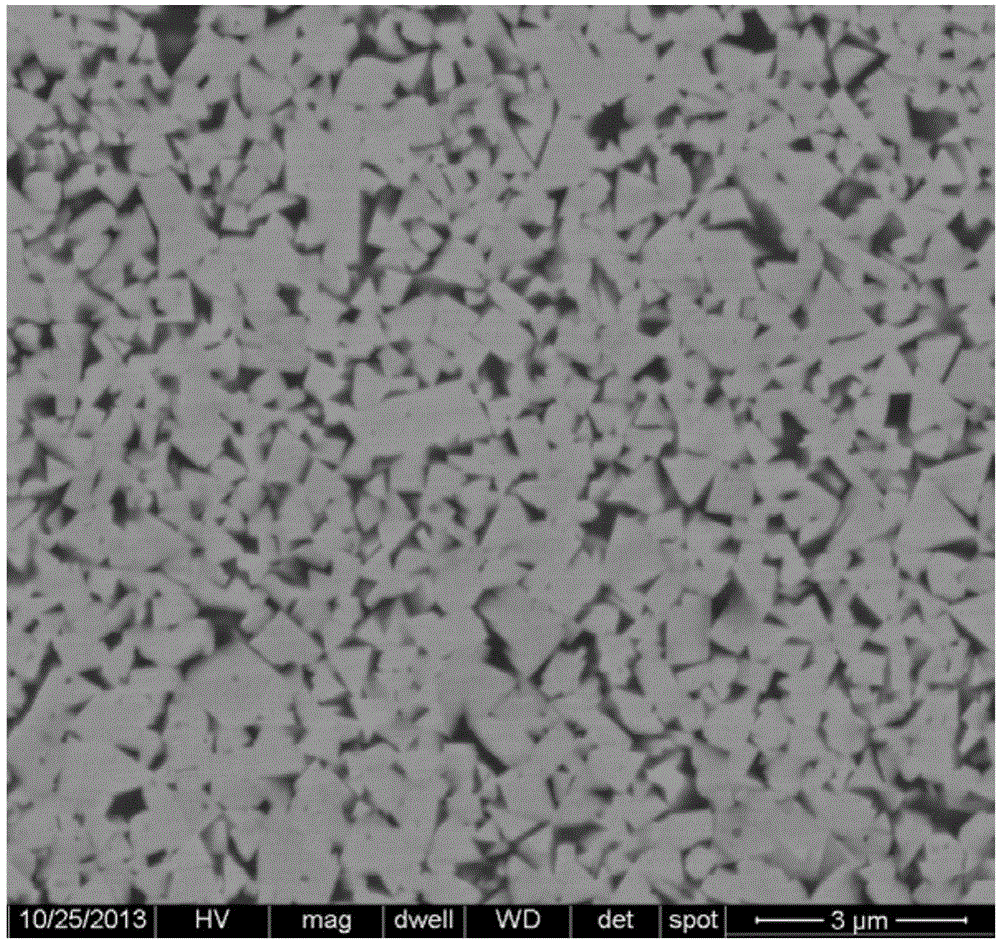

Embodiment 3

[0032] with WO 2.9 、Co 3 o 4 and carbon black as raw materials, according to the relationship between the composition of the cemented carbide and the relative magnetic saturation value, the carbon content in the raw material powder is regulated, so that the relative magnetic saturation value of the prepared cemented carbide bulk material is 84%, The above three raw material powders are mixed by ball milling, and the mixed powder is cold-pressed into a compact and sent to a vacuum furnace. The following process parameters are used to prepare WC-12Co composite powder in the vacuum furnace: heating rate 7°C / min, reaction temperature 1050°C , the holding time is 3 hours;

[0033] The VC powder with a particle size of 1.0-2.0 microns was ball milled and mixed with the prepared WC-12Co composite powder. The amount of VC powder added was 0.3wt.%. Anhydrous ethanol was used as the grinding medium, and the mass ratio of the ball to the powder was 4:1, the volume ratio of grinding me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com