Medical sacculus and preparation method thereof

A balloon and medical technology, which is applied in the field of medical devices, can solve the problems of high cost, drug shedding, and high requirements for the proficiency and professional level of processing personnel, so as to improve the specific surface area and roughness, and the preparation method is simple and reliable. Effects of Adhesion and Drug Loading Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

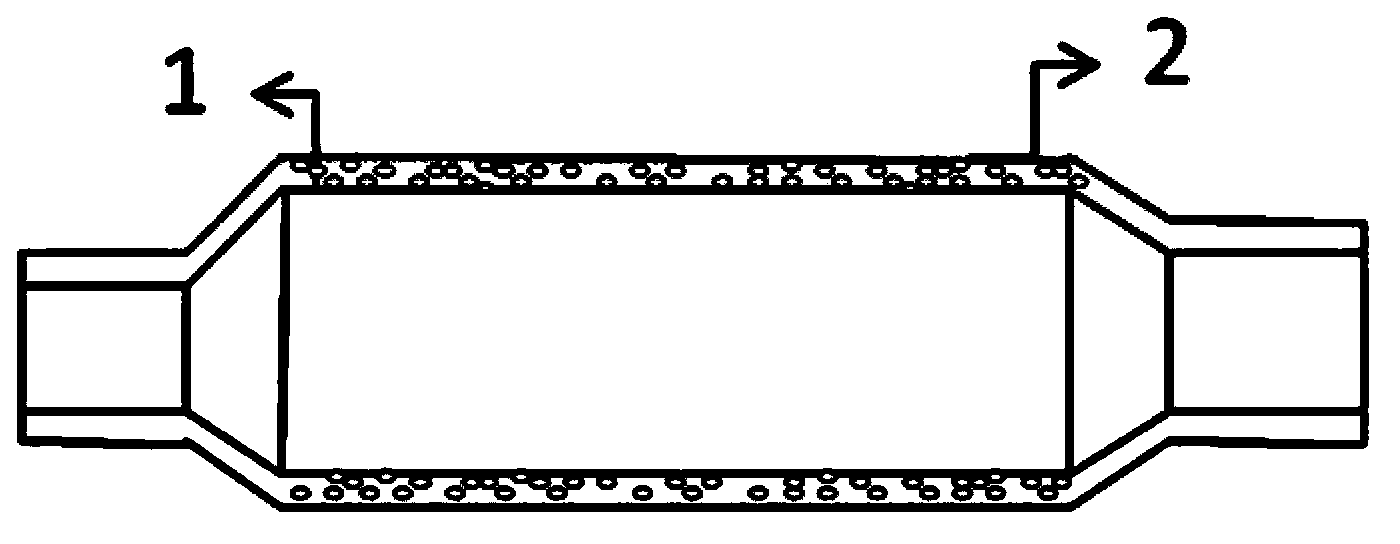

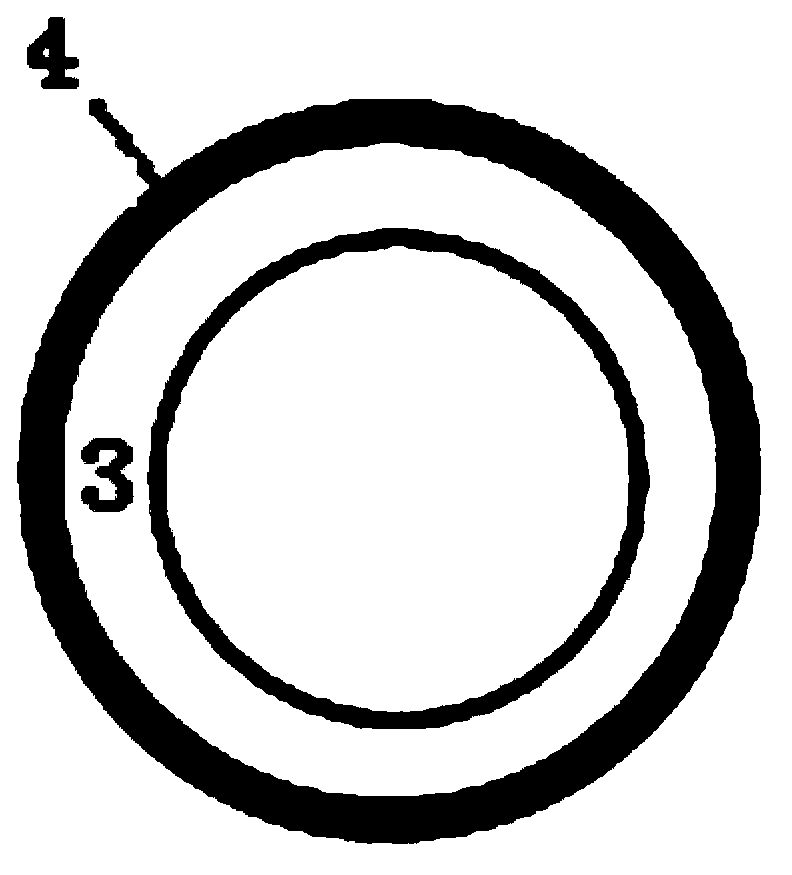

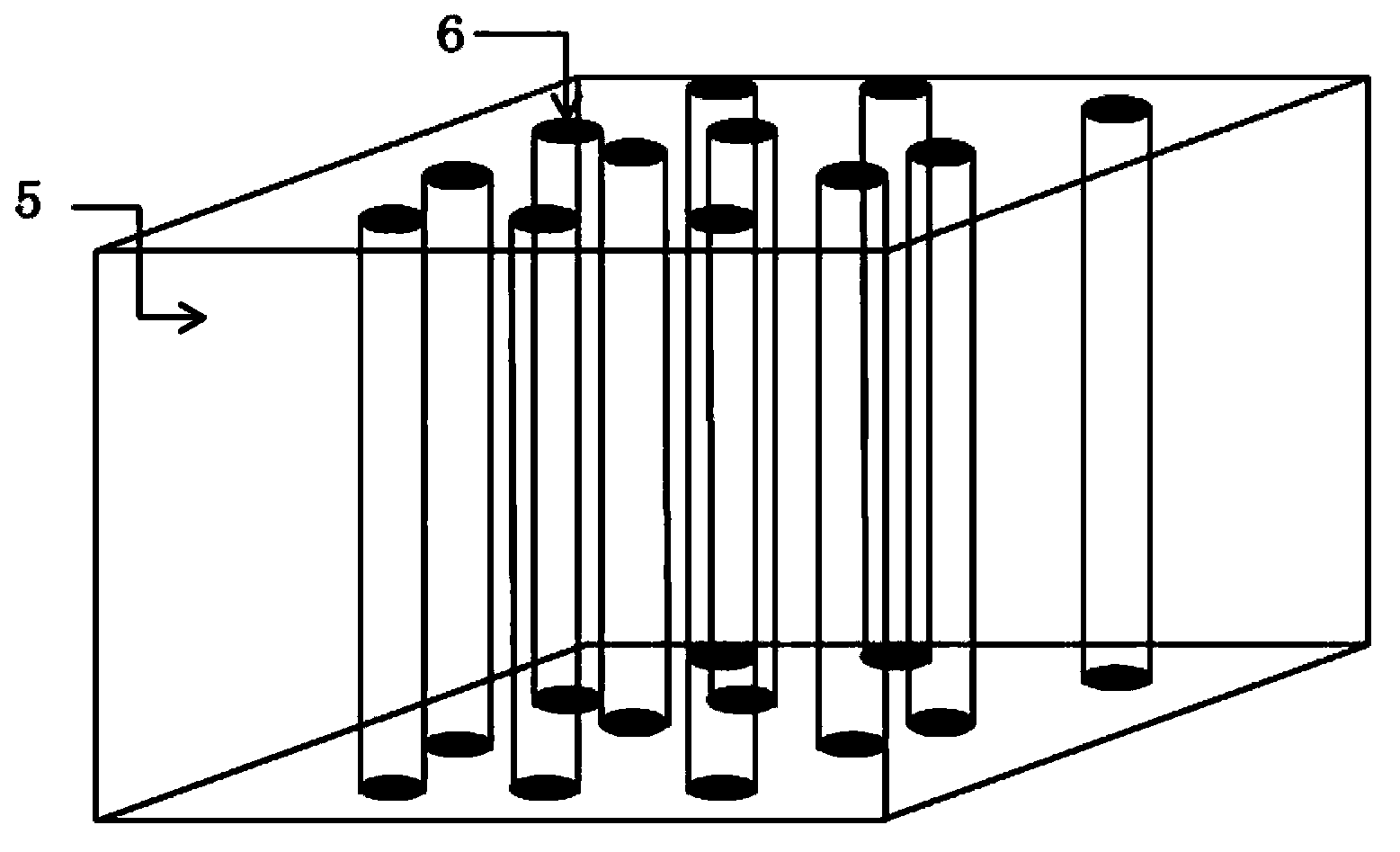

[0031] Pebax 6333 material and PEO material were melt-blended at 230°C through a twin-screw extruder at a volume ratio of 30:70 to prepare Pebax / PEO blended material. The pure Pebax7233 material and the Pebax / PEO blended material were prepared through a co-extrusion process to prepare a double-layer tube, and the outer diameter of the prepared tube was 0.040 inches, and the inner diameter was 0.022 inches. The inner layer of the pipe is Pebax7233 material, and the outer layer is Pebax / PEO blend material, wherein the outer layer has a cross-sectional area of 15%. The above pipe was stretched at a stretching ratio of 4.0 at 60°C. Insert the stretched tubing into the balloon mold of the balloon molding machine, form a balloon body with an outer diameter of 3.0mm at 90°C and a molding pressure of 490psi, and immediately heat-fix at 105°C for 30s and then water-cool. The prepared balloon body is ultrasonically oscillated in deionized water for 2 hours to dissolve the water-solub...

example 2

[0033] Nylon 12 / PVA blended material was prepared by melt blending nylon 12 material and PVA material at a volume ratio of 70:30 through a twin-screw extruder at 250 °C. The nylon 12 material and the nylon 12 / PVA blended material were prepared through a co-extrusion process to prepare a double-layer pipe, and the outer diameter of the prepared pipe was 0.028 inches, and the inner diameter was 0.015 inches. The inner layer of the pipe is nylon 12 material, and the outer layer is nylon 12 / PVA blend material, wherein the outer layer has a cross-sectional area of 30%. The above pipe was stretched at a stretching ratio of 3.5 at 60°C. Insert the stretched tubing into the balloon mold of the balloon forming machine, form a balloon body with an outer diameter of 2.0 mm at 90°C and a molding pressure of 500 psi, and immediately heat-fix at 110°C for 1 min and then water-cool. The prepared balloon body is ultrasonically oscillated in deionized water for 2 hours to dissolve the water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com