Carbocoal-based photo-catalytic oxidation fuel gas desulfurization and denitration agent and preparation method thereof

A technology of photocatalytic oxidation and denitration agent, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high energy consumption, high price, serious catalyst wear, etc. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

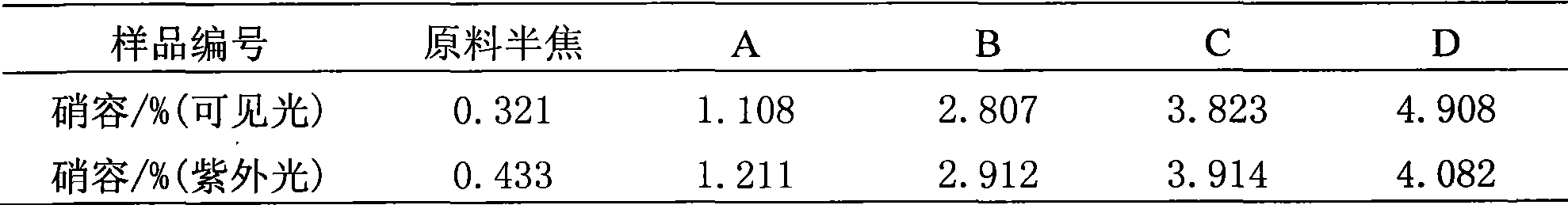

[0031] 100g of 4-10 mesh particles obtained after sieving semi-coke and 5.0% H 2 o 2 The solution was mixed with a liquid-solid ratio of 1.5, placed in a 500ml round-bottomed flask, kept in an ultrasonic environment at 80°C for 2h, and dried at 110°C for 2h; then mixed with 45% HNO 3 After mixing at a liquid-solid ratio of 2, treat at 80°C for 2 hours, wash with water until neutral, and then dry at 110°C for 2 hours; then mix the semi-finished semi-coke catalyst obtained in the above steps with 5.0% ammonia water at a liquid-solid ratio of 2 , treated at 40°C for 2 hours, washed with water until neutral and then dried at 110°C for 2 hours; then, the semi-finished semi-coke catalyst obtained in the above steps was divided into 4 parts on average, 1 part was marked as A, and the other 3 parts were added to 30ml tetrabutyl titanate Dissolve the ester in 100ml of absolute ethanol and stir at 35°C for 2 hours, place it for 6 hours, dry at 110°C for 4 hours, and roast at 350°C for ...

example 6~7

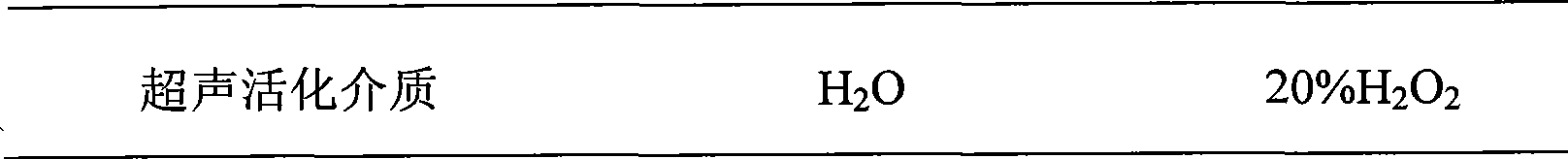

[0036] After sieving the semi-coke, 100g of 10-40 mesh particles were mixed with distilled water, 20.0% H 2 0 2 The solution was mixed at a liquid-solid ratio of 1.5, placed in a 500ml round bottom flask, kept in an ultrasonic environment of 150-300w for 2h, and dried at 110°C for 2h; then mixed with 40.0% H 2 SO 4 The solution was mixed according to the liquid-solid ratio of 3.0, treated at 80°C for 2h, washed with water until neutral and then dried at 110°C for 2h; 2 CO 3 The solution is mixed according to the liquid-solid ratio of 3.0, treated at 100°C for 1h, washed with water until neutral, and then dried at 110°C for 2h; then the semi-finished semi-coke catalyst obtained in the above steps is dissolved in 30ml of tetrabutyl titanate in 100ml of absolute ethanol After stirring at 40°C for 2h, soak in the solution obtained for 6h, and dry at 110°C for 6h to prepare the precursor of modified semi-coke photocatalytic adsorption desulfurization and denitrification agent. ...

example 8~13

[0042] After sieving the semi-coke, 100g of particles of 10-40 mesh and 15.0% H 2 o 2 The solution was mixed with a liquid-solid ratio of 1.5, placed in a 500ml round bottom flask, kept in a 150-300w ultrasonic environment for 2h, and dried at 110°C for 2h; then mixed with 40.0% HNO 3 Solution, 20.0% HNO 3Mix with 20.0% HCl mixed solution at a solid-to-liquid ratio of 2.0, react at 80°C for 2h, wash with water until neutral and then dry at 110°C for 2h, the semi-finished semi-coke catalysts obtained are respectively marked as G and H; KOH, 10.0% NaOH and 10.0% KOH mixed solution, a certain concentration of MDEA solution are mixed at a liquid-solid ratio of 1.5, kept at 100°C for 1h, washed with water to neutral 110°C and dried for 2h, after that, at 3-25% water vapor content and Under the condition of 2-15% oxygen content, activated at a temperature of 500-700°C, the semi-finished products of semi-coke catalysts are respectively recorded as G-K, G-K-Na, G-M, H-K, H-K-Na, H-M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com