A kind of preparation method of high-purity cesium sulfate

A cesium sulfate, high-purity technology, applied in chemical instruments and methods, rubidium/cesium/francium compounds, alkali metal compounds, etc., can solve problems such as easy decomposition of carbonic acid, safety accidents, increased costs, etc., to achieve loose process control, The effect of reducing operating requirements and improving product quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

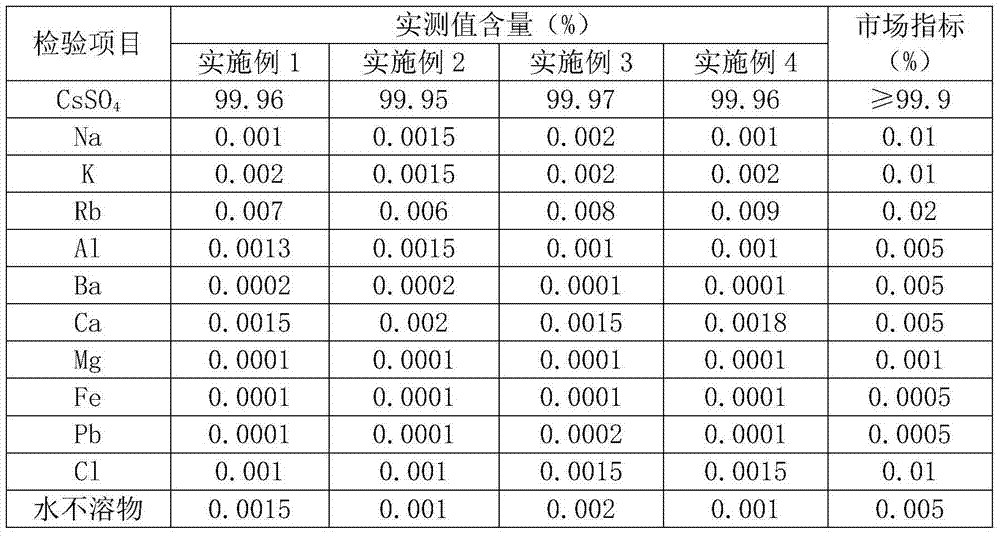

Examples

Embodiment 1

[0026] A kind of preparation method of high-purity cesium sulfate, its step is as follows:

[0027] 1. Acid leaching cesium garnet: put cesium garnet powder into 35wt% sulfuric acid for acid leaching, the liquid-solid mass ratio is 3:1, the reaction temperature is 130°C, the reaction time is 4h, and then keep above 90°C and filter to obtain acid leaching liquid;

[0028] 2. Naturally cool the pickling solution to room temperature to sink alum, centrifuge, separate the mother liquor and discharge it after neutralization treatment, add pure water to the separated cesium alum crystals for two recrystallizations, and the liquid-solid mass ratio of each recrystallization is 8: 1. After adding pure water to dissolve each time, heat, evaporate and concentrate to a temperature of 110°C, the volume is one-third of the original volume, and then naturally cool to room temperature to crystallize, and the recrystallized mother liquor returns to step 1;

[0029] 3. Dissolve the refined ces...

Embodiment 2

[0035] A kind of preparation method of high-purity cesium sulfate, its step is as follows:

[0036] 1. Acid leaching cesium garnet: put cesium garnet powder into 35wt% sulfuric acid for acid leaching, the liquid-solid mass ratio is 3:1, the reaction temperature is 130°C, the reaction time is 4h, and then keep above 90°C and filter to obtain acid leaching liquid;

[0037] 2. Naturally cool the pickling solution to room temperature to sink alum, centrifuge, separate the mother liquor and discharge it after neutralization treatment, add pure water to the separated cesium alum crystals for two recrystallizations, and the liquid-solid mass ratio of each recrystallization is 8: 1. After adding pure water to dissolve each time, heat, evaporate and concentrate to a temperature of 115°C, and the volume is one-third of the original volume, then naturally cool to room temperature to crystallize, and return the recrystallized mother liquor to step 1;

[0038] 3. Dissolve the refined cesi...

Embodiment 3

[0044] A kind of preparation method of high-purity cesium sulfate, its step is as follows:

[0045] 1. Acid leaching cesium garnet: put cesium garnet powder into 35wt% sulfuric acid for acid leaching, the liquid-solid mass ratio is 3:1, the reaction temperature is 130°C, the reaction time is 4h, and then keep above 90°C and filter to obtain acid leaching liquid;

[0046] 2. Naturally cool the pickling solution to room temperature to sink alum, centrifuge, separate the mother liquor and discharge it after neutralization treatment, add pure water to the separated cesium alum crystals for two recrystallizations, and the liquid-solid mass ratio of each recrystallization is 8: 1. After adding pure water to dissolve each time, heat, evaporate and concentrate until the temperature is 120°C, the volume is one-third of the original volume, and then naturally cool to room temperature to crystallize, and the recrystallized mother liquor returns to step 1;

[0047] 3. Dissolve the refine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com