Method for detecting p-nitrophenol by using PDDA (Poly Diallyldimethylammonium) functionalized graphene modified glassy carbon electrode

A technology of p-nitrophenol and glassy carbon electrodes, which is applied in the direction of material electrochemical variables, etc., can solve the problems of time-consuming equipment, high operating costs, restrictions on rapid and accurate measurement, and complicated operations, and achieve excellent specific surface area, simple operation, and detection The effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation method of PDDA functionalized graphene (PDDA-G)

[0041] Graphene oxide (GO) is firstly prepared for later use: it is prepared by the Hummer method.

[0042] 2.5 g K at room temperature 2 S 2 o 8 and 2.5 g P 2 o 5 Add to 12mL of concentrated sulfuric acid, stir well. Then add 1 gram of graphite powder and stir for 30 minutes to make the mixture uniform. Then the temperature was slowly raised to 80° C. for 4 hours. Then cool down to room temperature, wash repeatedly with secondary water until neutral, filter and dry at 60°C for 24 hours to obtain the preoxidized product. Then weigh 1 gram of the pre-oxidized product and add it to 36 mL of concentrated sulfuric acid that had been cooled to 0°C in advance, and stir for 30 minutes to make it evenly mixed. Then slowly add 5 g KMnO 4 Keep the temperature below 10°C. Stir for 30 minutes to mix well. The temperature was raised to 35°C, and the reaction was carried out for 8 hours. Then add 360mL of sec...

Embodiment 2

[0046] Method for modifying glassy carbon electrodes with PDDA functionalized graphene

[0047] 1) Take 50 mL of 1mg·mL -1 Graphene oxide solution, sonicated for 4h. Add 1 mL of 20% PDDA solution into 50 mL of secondary water, mix well, then add the graphene oxide solution into the PDDA solution under magnetic stirring, continue stirring for 30 min, add 1.5 mL of hydrazine hydrate (80%), and stir well Then put it in a hydrothermal kettle and react at 100°C for 3h, after cooling, centrifuge and wash with secondary water, and vacuum dry at 60°C to obtain PDDA functionalized graphene. The PDDA-functionalized graphene was dispersed in water to form a 1 mg / ml PDDA-functionalized graphene suspension.

[0048] 2) The glassy carbon electrode was polished to a mirror surface with 0.3 μm and 0.05 μm Al2O3 suspension in turn, and then ultrasonically cleaned with 95% ethanol and double distilled water in turn to obtain the treated glassy carbon electrode ;

[0049] 3) Dry the glassy...

Embodiment 3

[0051] A method for detecting p-nitrophenol

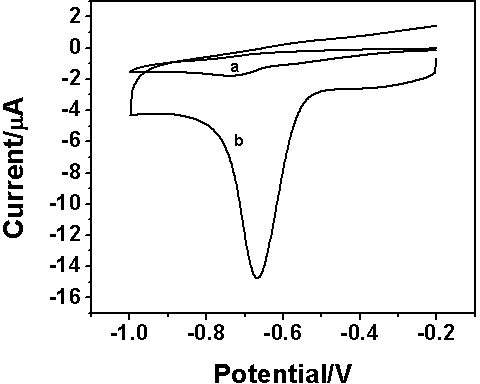

[0052] 1) The PDDA-functionalized graphene-modified electrode was placed in a phosphate buffer solution containing p-nitrophenol at pH 7, with a platinum wire electrode as the counter electrode and an Ag / AgCl electrode as the reference electrode, and PDDA functionalized The graphene-modified electrode and the bare electrode were used as working electrodes. from figure 2 It can be seen that compared with the bare electrode (a), the PDDA-functionalized graphene-modified electrode (b) has a good catalytic effect on the detection of p-nitrophenol, greatly improving The reduction potential of p-nitrophenol was determined.

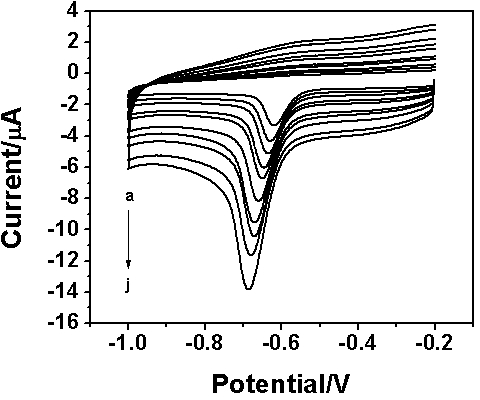

[0053] 2) The graphene-modified electrode functionalized by PDDA contained 1×10 -4 mol L -1 0.2mol L of p-nitrophenol -1 Cyclic voltammetry curves of different scan rates in phosphate buffer at pH 7 ( image 3 ) and the linear relationship between scan rate and peak current ( Figure 4 ) It can be seen th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com