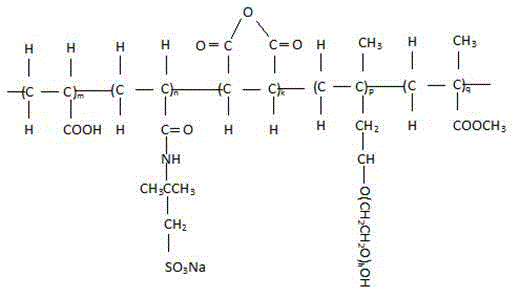

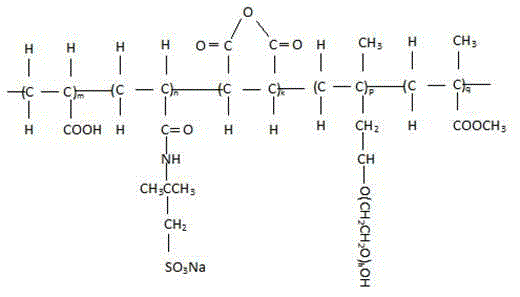

Polycarboxylate superplasticizer masterbatch capable of prolonging coagulating time of concrete and preparation method thereof

A technology of setting time and polycarboxylic acid, applied in the field of polycarboxylate superplasticizer masterbatch and its preparation, can solve the problems of waste of concrete and the rising cost of compounding pumping agent, and achieve the effect of prolonging the setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Add 300g of prenol polyoxyethylene ether, 10g of maleic anhydride, and 400g of water into a three-neck flask with a capacity of 1000ml, start stirring to fully dissolve it, and heat it up to 65°C for use;

[0032] A material configuration: Add 4g of ammonium persulfate, 8.5g of 2-acrylamide-2-methylpropanesulfonate sodium and 150g of water into a 250ml beaker, stir and mix evenly, make it fully dissolved, and set aside;

[0033] B material configuration: Add 34g of acrylic acid, 5g of isopropanol, and 6.8g of methyl methacrylate into a 50ml beaker, stir and mix evenly, make it fully dissolved, and set aside;

[0034] 2. Add material A and material B dropwise to the three-necked flask at the same time, finish dropping in 4.5 hours, and keep the temperature constant during the dropping process;

[0035] 3. After the dropwise addition is completed, keep the temperature constant and heat-preserve for 1 hour;

[0036] 4. Cool down to 45°C and discharge.

Embodiment 2

[0038] 1. Add 300g of prenol polyoxyethylene ether, 10g of maleic anhydride, and 400g of water into a three-neck flask with a capacity of 1000ml, start stirring to fully dissolve it, and heat it up to 75°C for use;

[0039] A material configuration: Add 5g sodium persulfate, 8.5g 2-acrylamide-2-methylpropanesulfonate sodium and 150g water into a 250ml beaker, stir and mix evenly, make it fully dissolved, and set aside;

[0040] B material configuration: Add 34g of acrylic acid, 5g of isopropanol, and 6.8g of methyl methacrylate into a 50ml beaker, stir and mix evenly, make it fully dissolved, and set aside;

[0041] 2. Add material A and material B dropwise to the three-necked flask at the same time, finish dropping in 4.5 hours, and keep the temperature constant during the dropping process;

[0042] 3. After the dropwise addition is completed, keep the temperature constant and heat-preserve for 1 hour;

[0043] 4. Cool down to 45°C and discharge.

Embodiment 3

[0045] 1. Add 300g of prenol polyoxyethylene ether, 10g of maleic anhydride, and 400g of water into a three-necked flask with a capacity of 1000ml, start stirring to fully dissolve it, and heat it up to 85°C for use;

[0046] A material configuration: Add 6g potassium persulfate, 8.5g 2-acrylamide-2-methylpropanesulfonate sodium and 150g water into a 250ml beaker, stir and mix evenly, make it fully dissolved, and set aside;

[0047] B material configuration: Add 34g of acrylic acid, 5g of isopropanol, and 6.8g of methyl methacrylate into a 50ml beaker, stir and mix evenly, make it fully dissolved, and set aside;

[0048] 2. Add material A and material B dropwise to the three-necked flask at the same time, finish dropping in 4.5 hours, and keep the temperature constant during the dropping process;

[0049] 3. After the dropwise addition is completed, keep the temperature constant and heat-preserve for 1 hour;

[0050] 4. Cool down to 45°C and discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com