Concrete admixture suitable for fine aggregate as tunnel hole slag and preparation method of concrete admixture

A concrete admixture and fine aggregate technology, which is applied in the field of building materials, can solve problems such as poor appearance quality and poor workability, and achieve the effects of improving surface appearance, promoting recycling, and realizing high-quality sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

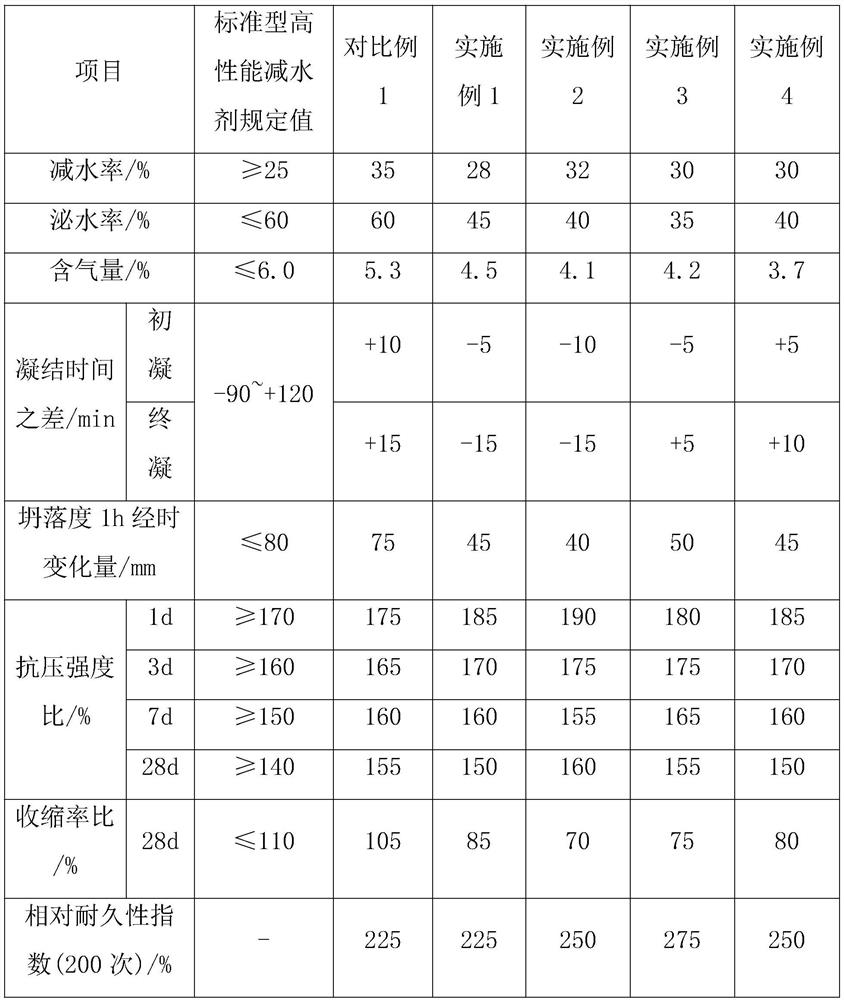

Examples

Embodiment 1

[0039]The present embodiment relates to a concrete admixture suitable for fine aggregate as tunnel slag, by weight percentage, consisting of the following raw materials: polyethylene glycol 3.5%, methacrylic acid 9.2%, acrylic acid 5.5%, ammonium persulfate 1.1%, vitamin C 0.5%, sodium hydroxide 0.4%, sodium sulfate 0.4%, hydrogen peroxide 0.8%, allyl alcohol 6.0%, polyoxyethylene ether 7.0%, mercaptoacetic acid 4%, p-benzool 1.5%, phenothiazine 4.2%, Styrene 0.8%, deionized water 55.1%, the sum of the weight percentage of raw materials is 100%.

[0040] The present embodiment relates to a concrete admixture preparation method suitable for fine aggregates as tunnel cavity slag, performed in accordance with the following steps:

[0041] Step 1: Weigh each raw material separately according to the quality ratio of the above raw materials;

[0042] Step two, the polyethylene glycol, methacrylic acid and acrylic acid in turn into three beakers, control the reaction temperature of 50 °...

Embodiment 2

[0048]Example 2 relates to a concrete admixture suitable for fine aggregates as tunnel slag, by weight percentage, consisting of the following raw materials: polyethylene glycol 4.2%, methacrylic acid 7.3%, acrylic acid 6.1%, ammonium persulfate 0.8%, vitamin C 0.7%, sodium hydroxide 0.3%, sodium sulfate 0.6%, hydrogen peroxide 0.6%, allyl alcohol 4.3%, polyoxyethylene ether 9.2%, mercaptoacetic acid 3%, p-benzenediol 2.3%, phenothiazine 3.1%, Styrene 1.1%, deionized water 56.4%. The sum of the weight percentages of raw materials is 100%. The preparation method of the present example 2 is the same as that of Example 1.

Embodiment 3

[0050] Example 3 relates to a concrete admixture suitable for fine aggregate as tunnel slag, by weight percentage, consisting of the following raw materials: polyethylene glycol 5.0%, methacrylic acid 6.1%, acrylic acid 7.4%, ammonium persulfate 0.6%, vitamin C 0.9%, sodium hydroxide 0.2%, sodium sulfate 0.8%, hydrogen peroxide 0.5%, allyl alcohol 3.5%, polyoxyethylene ether 11.4%, mercaptoacetic acid 2%, 3.0% of p-phenylphenol, phenothiazine 2.4%, Styrene 1.5%, deionized water 54.7%. The sum of the weight percentages of raw materials is 100%. The preparation method of the present embodiment 3 is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com