High-yield natural astaxanthin fermentation method

A technology of natural astaxanthin and fermentation method, which is applied in the field of microbial fermentation production, can solve the problems of low astaxanthin production, achieve the effects of increasing dissolved oxygen, promoting oxygen transfer, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

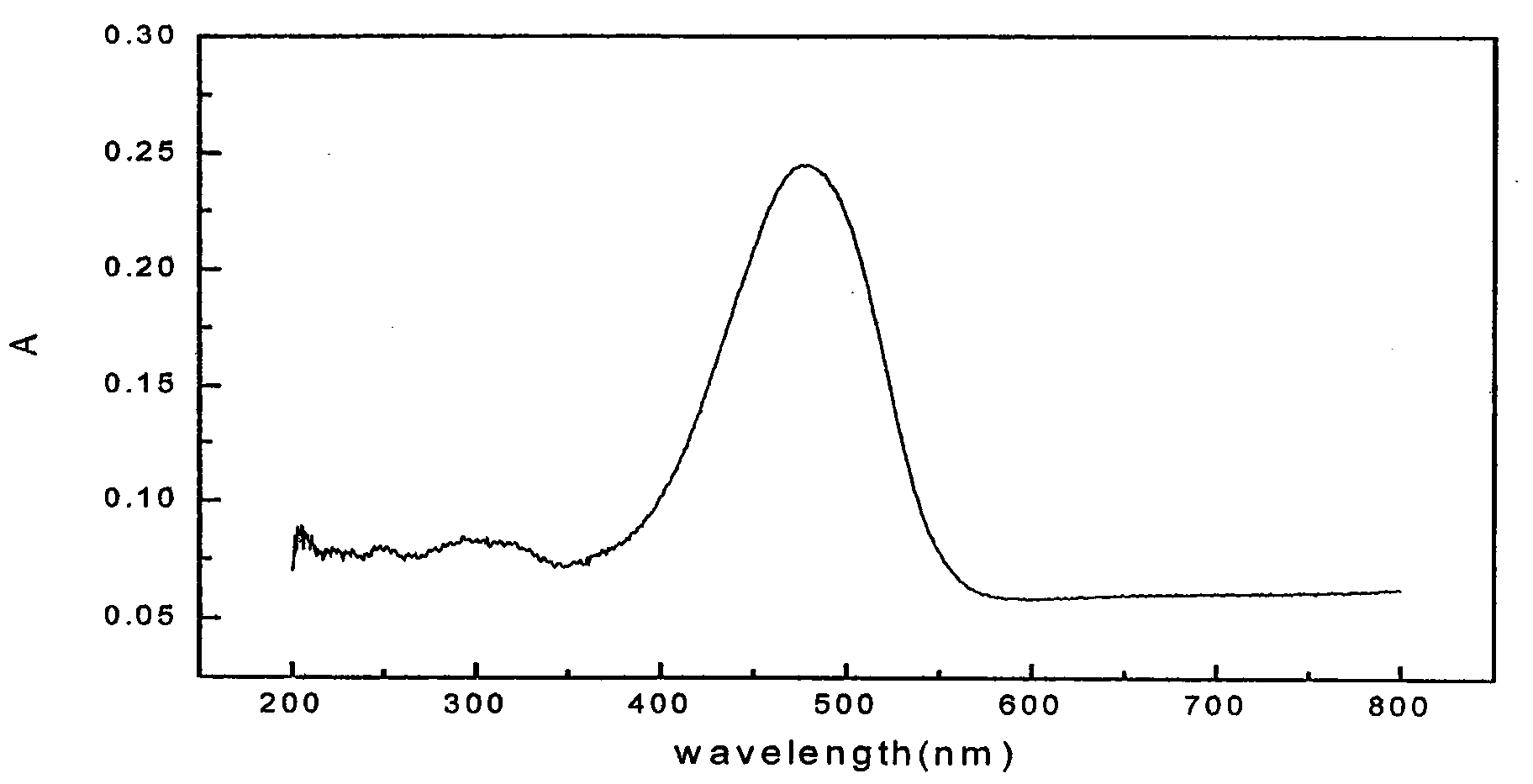

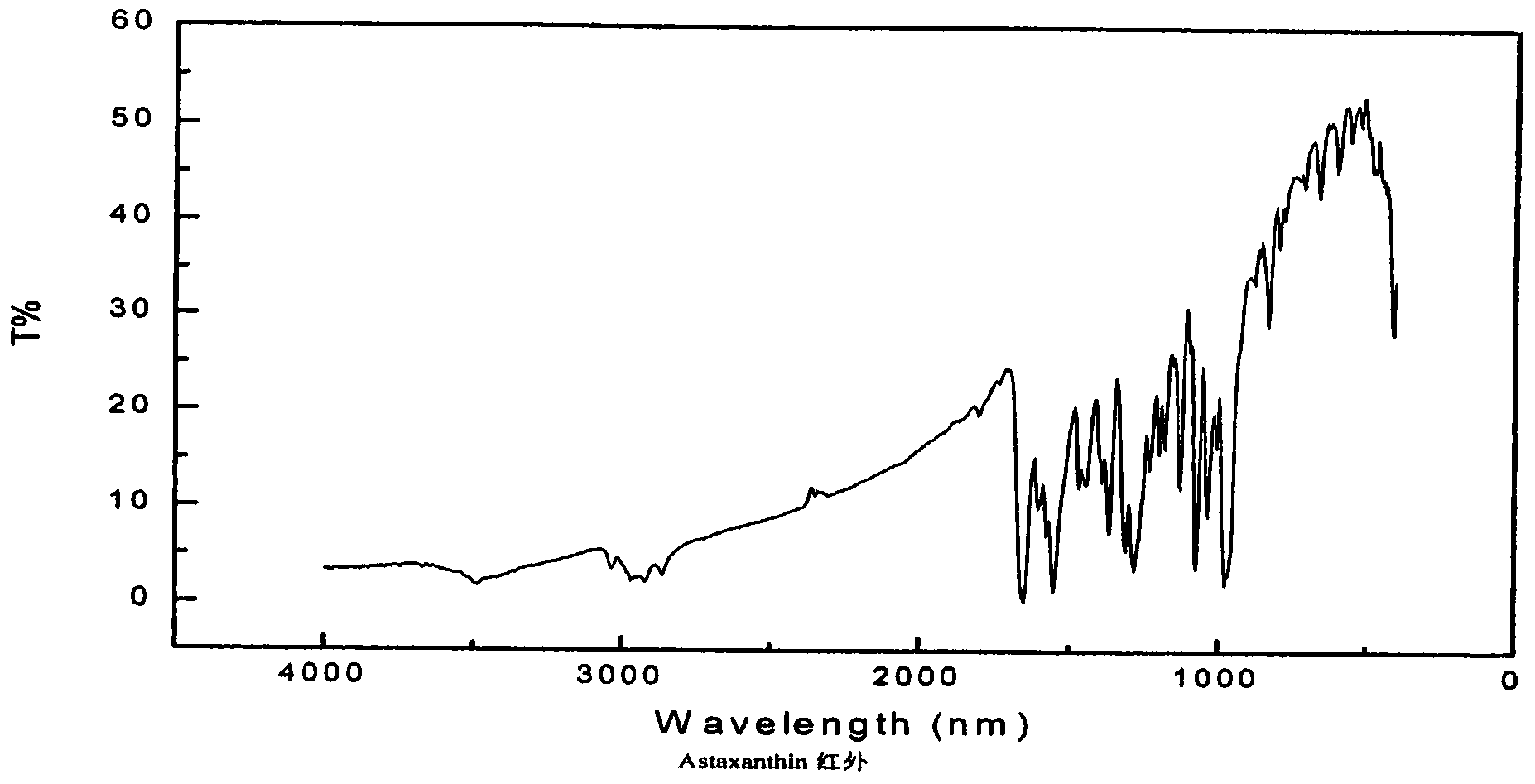

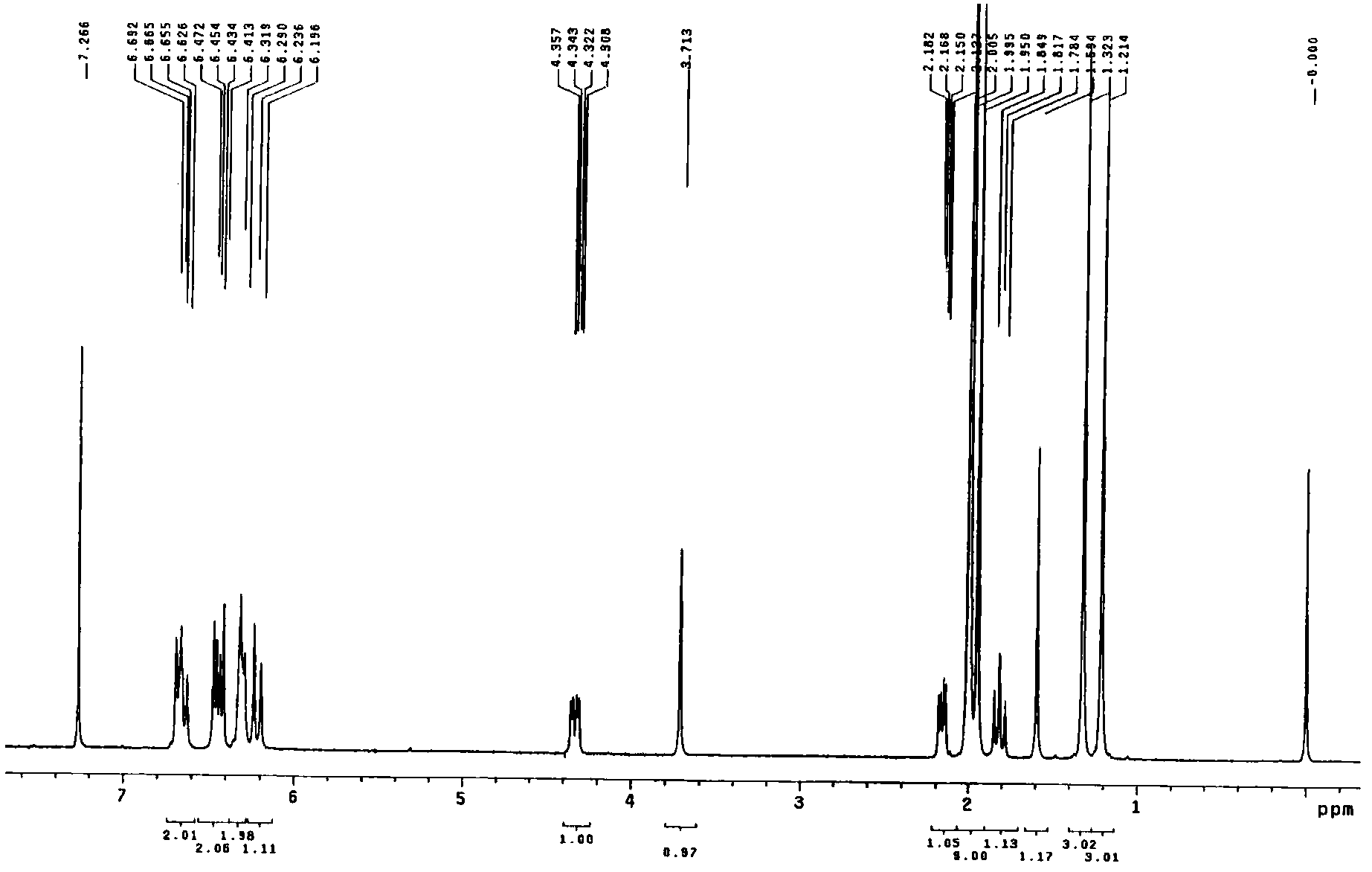

Image

Examples

Embodiment 1

[0056] The optimization of embodiment 1 astaxanthin fermentation conditions

[0057] 1. Optimization of oxygen carrier

[0058] (1) Inoculate the activated slant strain into a 250mL Erlenmeyer flask containing 30mL liquid YM medium, culture at 22±1°C, 180r / min for 20h; then inoculate 10% of the inoculum into a 100mL shake flask for fermentation In a 1000mL Erlenmeyer flask with base, culture at 22±1°C, 180r / min for 20h.

[0059] (2) The volume of the fermenter is 10 L, and the filling volume is 6 L. At the same time, oxygen carriers are added to the fermentation medium, and the fermentation is sterilized at 121° C. for 20 minutes. After cooling, inoculate the seed culture solution into the fermentation medium according to 10% inoculum amount for fermentation and cultivation. The cultivation temperature is 22±1°C, and the fermentation pH is controlled to be 5.0±0.5 by feeding 2mol / L NaOH and 2mol / L HCl, and the ventilation rate is 1.2 vvm, by adjusting the stirring speed to c...

Embodiment 2

[0105] The application of embodiment 2 natural astaxanthin

[0106] 1. Feed additives containing astaxanthin on egg production and hatching rate of snake snapping turtles and on the survival and growth of young turtles

[0107] (1)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com