Wide-band oxygen sensor chip and manufacturing method thereof

The technology of an oxygen sensor and its manufacturing method is applied in the field of wide-range oxygen sensor chip and its manufacturing, wide-range oxygen sensor chip and its manufacturing field, which can solve the problem that engine fuel control is not very accurate, and the degree of concentration is not known, etc. problems, achieve the effect of preventing cracking and shrinkage mismatch, improving bond strength and yield, and ensuring signal sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

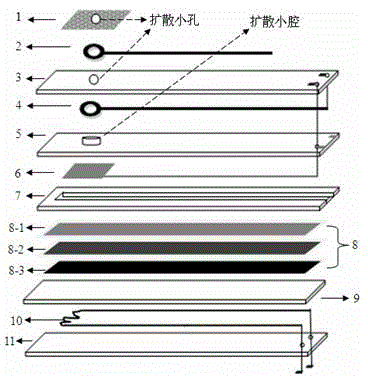

[0037] Oxygen sensor chip preparation

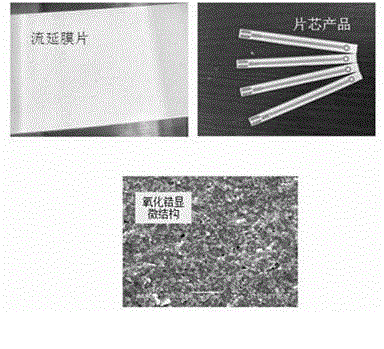

[0038] 1) Cast film preparation: Weigh 8mol% YSZ powder according to the ratio, put it into a ball mill tank, add solvent absolute ethanol, dispersant triethanolamine, binder polyvinyl butyral, plasticizer in sequence Dibutyl phthalate and polyethylene glycol were ball milled in a ball mill tank for 25 hours to make casting slurry;

[0039] 2) Using the tape casting process, use a scraper to scrape a uniform film with a thickness of 250 μm, dry it in a fully automatic casting machine at a temperature of 70°C for 3 minutes, and cut to obtain the film;

[0040] 3) Fabrication of the germ layer: use the cast diaphragm obtained in step 2), stack it to a thickness of 500 μm, compact it with a press table, and cut it into pump battery dielectric layers, reference battery dielectric layers, air chamber layers and substrate layers;

[0041] 4) Print platinum ring electrodes on the front and back of the pump battery medium layer prepared in step...

Embodiment 2

[0051] Oxygen sensor chip preparation

[0052] 1) Cast film preparation: Weigh 8mol% YSZ powder according to the ratio, put it into a ball mill tank, add solvent absolute ethanol, dispersant triethanolamine, binder polyvinyl butyral, plasticizer in sequence Dibutyl phthalate and polyethylene glycol were ball milled in a ball mill tank for 30 hours to make casting slurry;

[0053] 2) Using the casting process, use a scraper to scrape a uniform membrane with a thickness of 300 μm, dry it in a fully automatic casting machine at a temperature of 70°C for 4 minutes, and cut to obtain the membrane;

[0054] 3) Fabrication of the germ layer: use the cast diaphragm obtained in step 2), stack it to a thickness of 500 μm, compact it with a press table, and cut it into pump battery dielectric layers, reference battery dielectric layers, air chamber layers and substrate layers;

[0055] 4) Print platinum ring electrodes on the front and back of the pump battery medium layer prepared in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Insulation resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com