Rare earth complex red fluorescent material and preparation method and application thereof

A technology of rare earth complexes and luminescent materials, applied in the field of rare earth luminescent materials and rare earth complex luminescent materials, can solve the problems of insufficient luminous efficiency and thermal stability of rare earth complex luminescent materials, and achieve improved luminous efficiency and thermal stability, The effect of simple raw materials and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Rare earth complex polycrystalline powder Eu(TTA) 3 Preparation of (QPO):

[0029] 1). Weigh 0.5mmol of Eu(NO 3 ) 3 ·6H 2 O and 1.5mmol α-thienoyltrifluoroacetone were added to dissolve in 10mL of acetonitrile, and 3mL of 0.5mol / L sodium hydroxide solution was added dropwise, and stirred thoroughly to obtain a clear solution A;

[0030] 2). Weigh 0.5 mmol 2-(2-benzoxazole) quinoline, add 5 mL of acetonitrile to fully dissolve, and obtain light-colored clear solution B;

[0031] 3). Slowly add solution B to solution A, and react at room temperature for 1 hour to obtain solution C. Solution C is evaporated under reduced pressure, washed with water, and dried at 60°C to obtain a light-colored powder, which is the rare earth luminescent material Eu(TTA) 3 (QPO) in 74% yield.

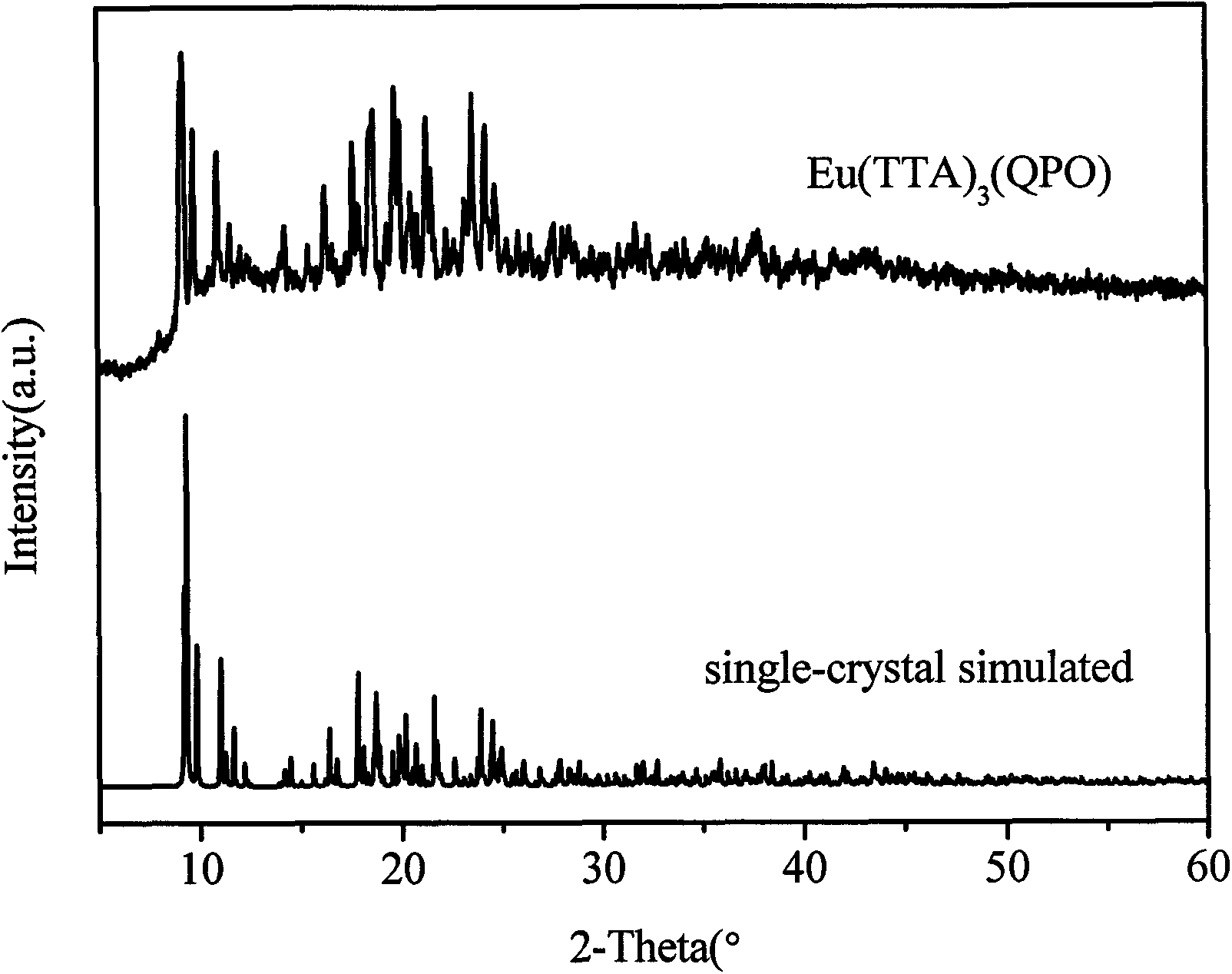

[0032] For rare earth luminescent material Eu(TTA) 3 (QPO) pure samples were subjected to a series of characterization and performance tests. The polycrystalline powder of the material of the p...

Embodiment 2

[0034] Rare earth luminescent material Eu(TTA) 3 (QPO) single crystal growth and characterization:

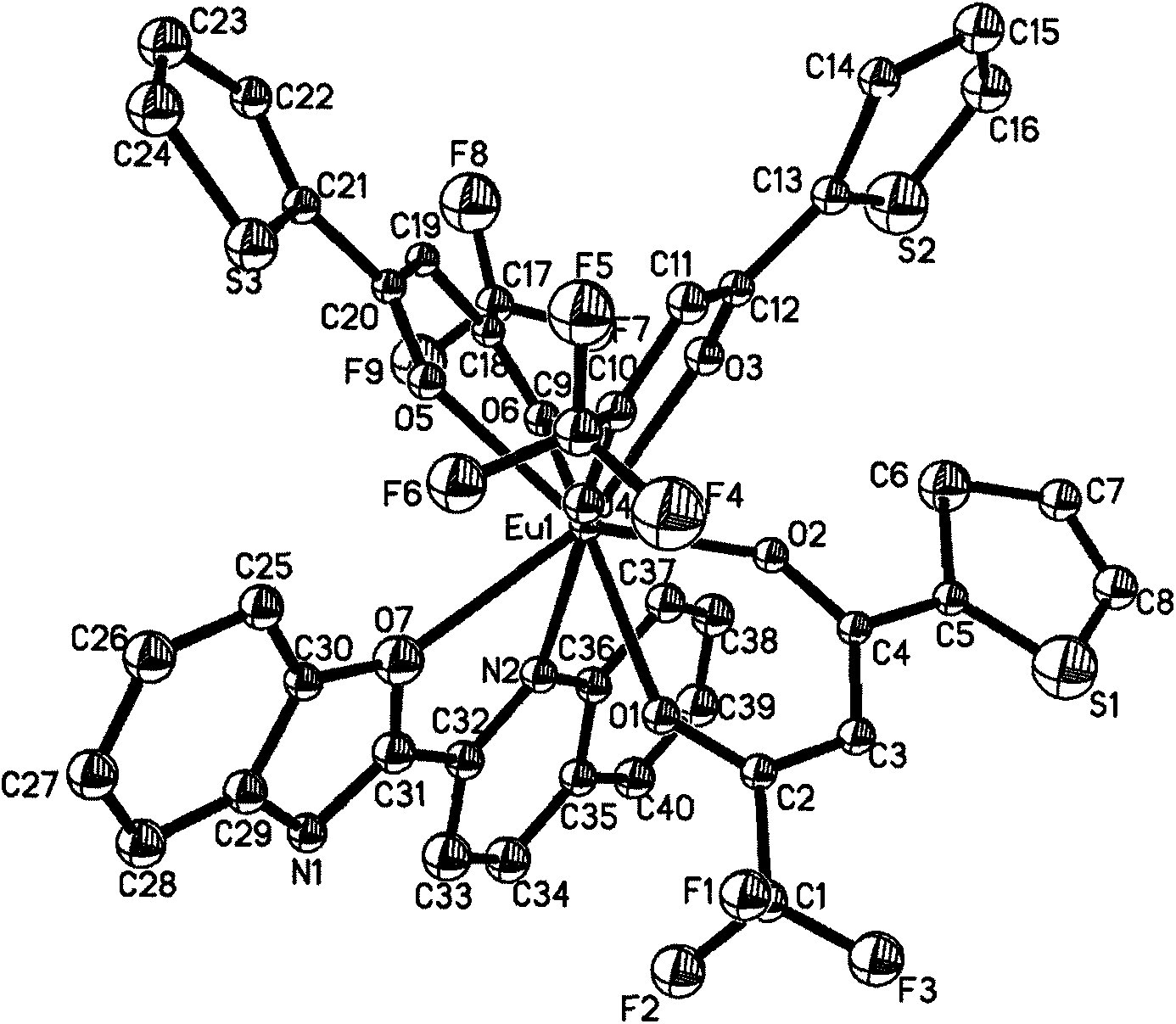

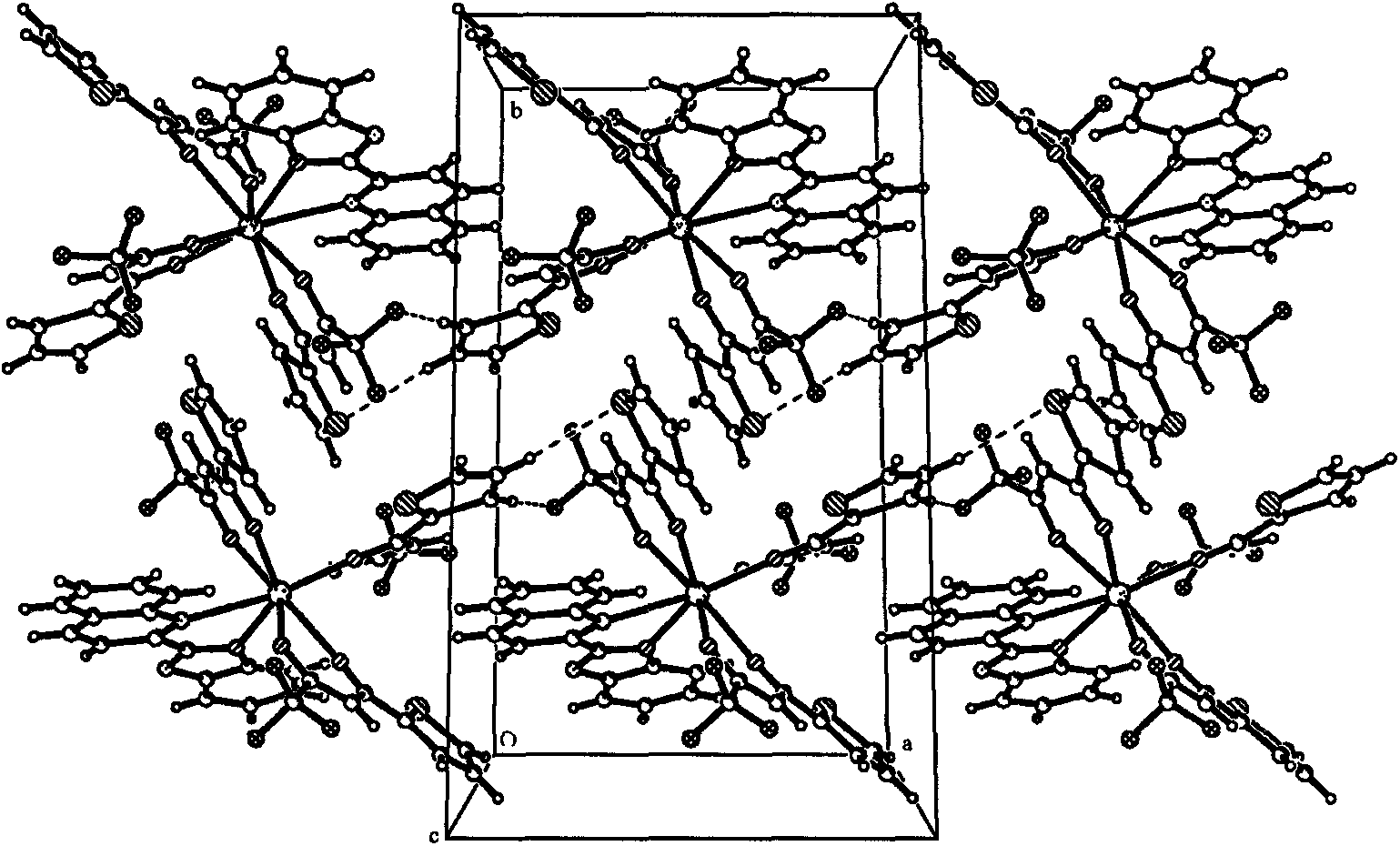

[0035] Take a small amount of Eu(TTA) 3 (QPO) pure sample powder, dissolved with dichloromethane to obtain a saturated solution S, in turn add solution S, dichloromethane and n-hexane equal volume mixed solution, n-hexane (the volume ratio of the three is 1:1.5:1) ). After standing still for several days, a yellow transparent block crystal was obtained, and a single crystal with a size of 0.39mm×0.32mm×0.28mm was picked for X-ray single crystal diffraction, and Eu(TTA) was obtained by analysis 3 (QPO) molecular structure. The molecular structure of the compound is shown in the appendix figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com