Method of forming a fin field effect transistor

A fin-type field effect, transistor technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as blocking source and drain surface epitaxial layers, short circuits, etc., to increase size, reduce resistance, The effect of increasing the drive current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

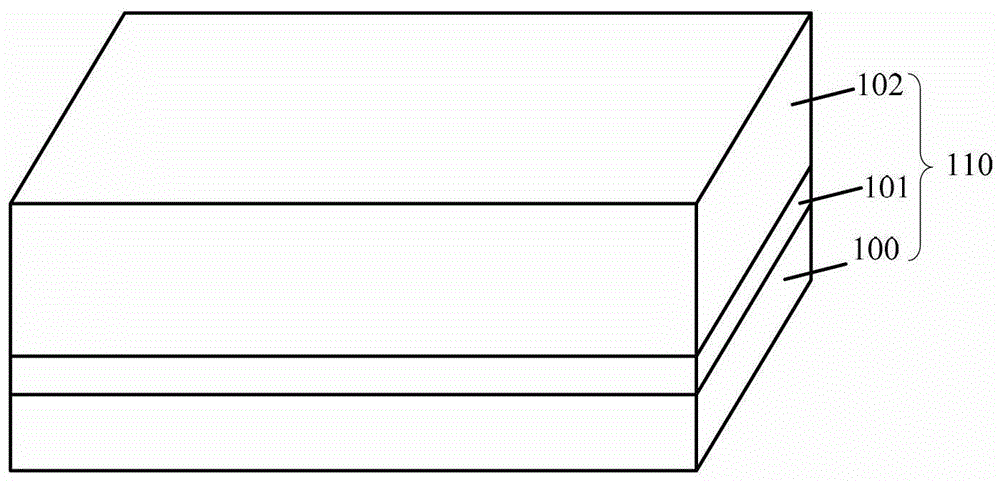

[0035] Please refer to figure 2 , providing a semiconductor substrate 110 .

[0036] The material of the semiconductor substrate 110 includes semiconductor materials such as silicon, germanium, silicon germanium, gallium arsenide, etc., and may be a bulk material or a composite structure such as silicon-on-insulator or germanium-on-insulator. Those skilled in the art can select the type of the semiconductor substrate 110 according to the semiconductor devices formed on the semiconductor substrate 110 , so the type of the semiconductor substrate should not limit the protection scope of the present invention.

[0037] In this embodiment, the material of the semiconductor substrate 110 used is silicon-on-insulator, including a silicon substrate layer 100 , a middle silicon oxide layer 101 and a single crystal silicon top layer 102 .

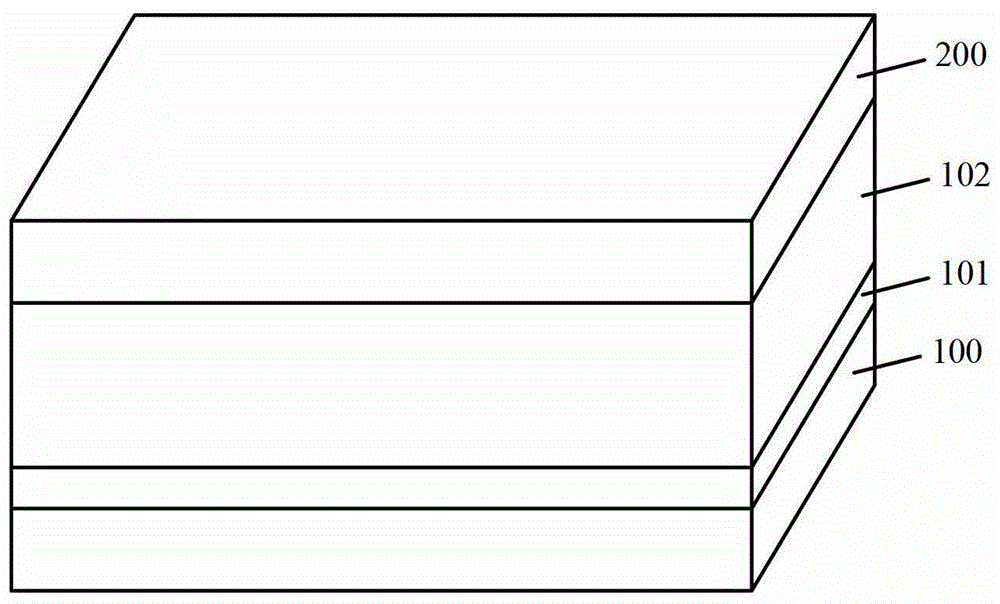

[0038] Please refer to image 3 , forming a hard mask material layer 200 on the surface of the semiconductor substrate 110 .

[0039] Specifica...

no. 2 example

[0070] This embodiment also provides another method for forming a FinFET.

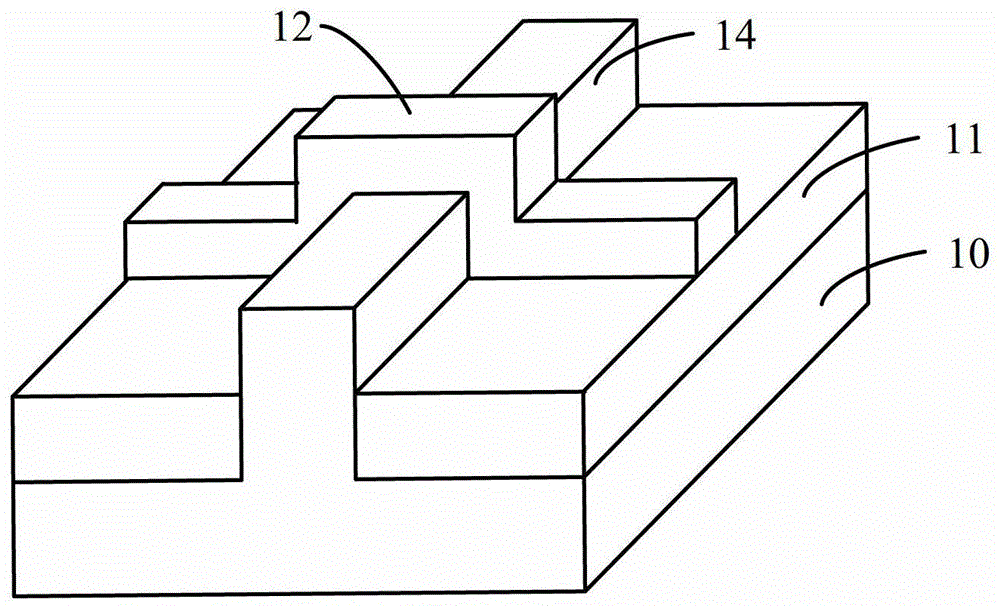

[0071] Please refer to Figure 17 , using the same method as the first embodiment, after forming the hard mask layer 201 on the surface of the substrate, etching the semiconductor substrate to form the pre-processing fins 500 .

[0072] Please refer to Figure 18 , growing an epitaxial layer 501 on the sidewall of the pre-processing fin, the pre-processing fin 500 and the epitaxial layer 501 on both sides thereof form a fin 510 .

[0073] Specifically, in this embodiment, the material of the epitaxial layer 501 is silicon. In other embodiments of the present invention, the material of the epitaxial layer 501 may also be silicon germanium or silicon carbide. The epitaxial layer 501 can be a single-layer silicon, silicon germanium or silicon carbide structure, or a multi-layer structure formed of multiple layers of different materials. For example, a layer of germanium is first grown on the sidewall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com