Preparation method of nano-silica reinforced meta-aramid paper

A nano-silica and aramid paper technology, applied in the field of papermaking, can solve the problems of paper becoming brittle, increasing paper porosity, performance differences, etc., to improve the compressive strength, avoid negative effects, and the steps are simple and easy to implement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

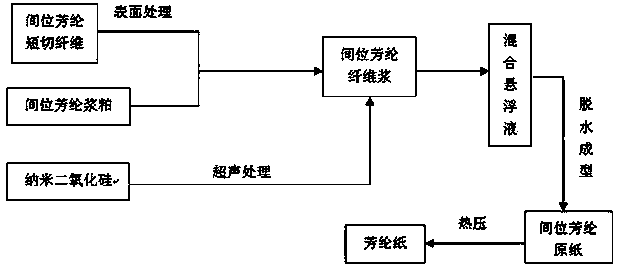

[0033] A preparation method for nano-silica reinforced meta-aramid paper, comprising the following steps:

[0034] 1) Take 20-50 parts of meta-aramid chopped fibers with a length of 2-8mm and add them to the aqueous surfactant solution for surface pretreatment; the pretreatment operation is as follows: the molar concentration is 1.0×10 -3 -3.0×10 -3 mol / L surfactant solution, at a temperature of 30-90°C, treat the surface of meta-aramid chopped fibers for 20-60min. The purpose of pretreatment is to remove the solvent, coagulant and other organic solvents used in the spinning process of meta-aramid chopped fibers, improve the hydrophilicity of meta-aramid chopped fibers, and facilitate the production of meta-aramid chopped fibers dispersion in water.

[0035] Wherein the surfactant is one or more of sodium dodecylbenzenesulfonate, sodium dodecylsulfonate and polyethylene glycol.

[0036] 2) Take 50-80 parts of the meta-aramid pulp, mix the meta-aramid pulp with the meta-aram...

Embodiment 1

[0042] A preparation method for nano-silica reinforced meta-aramid paper, comprising the following steps:

[0043] 1) Prepare a sodium dodecylbenzenesulfonate solution at 50°C with a molar concentration of 1.0×10 -3 mol / L, add a certain amount of meta-aramid chopped fibers, and treat at constant temperature for 20 minutes;

[0044] 2) After mixing the meta-aramid chopped fibers with a length of 5 mm and the meta-aramid pulp at a mass ratio of 3:7 treated with sodium dodecylbenzene sulfonate solution, they were deflagged in a fiber deflaker, and then Add 3 mL of polyethylene oxide solution with a mass fraction of 0.01% during the deflaking process to improve the dispersion of meta-aramid chopped fibers, and obtain meta-aramid fiber pulp after the treatment is completed;

[0045] 3) Weigh nano-silica containing 5% of the total mass of meta-aramid chopped fibers and meta-aramid pulp, and make a suspension of nano-silica and deionized water at a mass ratio of 2:100, and use Add ...

Embodiment 2

[0049] A preparation method for nano-silica reinforced meta-aramid paper, comprising the following steps:

[0050] 1) Prepare a sodium dodecylbenzenesulfonate solution at 60°C with a molar concentration of 2.0×10 -3 mol / L, add a certain amount of meta-aramid chopped fibers, and treat at constant temperature for 40 minutes;

[0051] 2) After mixing the meta-aramid chopped fibers with a length of 6mm treated with sodium dodecylbenzenesulfonate solution and meta-aramid pulp at a mass ratio of 4:6, they were deflagged in a fiber deflattering machine, and then Add 4 mL of polyethylene oxide solution with a mass fraction of 0.02% during the deflaking process to obtain meta-aramid fiber pulp;

[0052] 3) Weigh nano-silica containing 10% of the mass sum of meta-aramid chopped fibers and meta-aramid pulp, make a suspension of nano-silica and deionized water at a mass ratio of 3:100, and use Ultrasound for 10 minutes and then add to the meta-aramid fiber slurry obtained above to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com