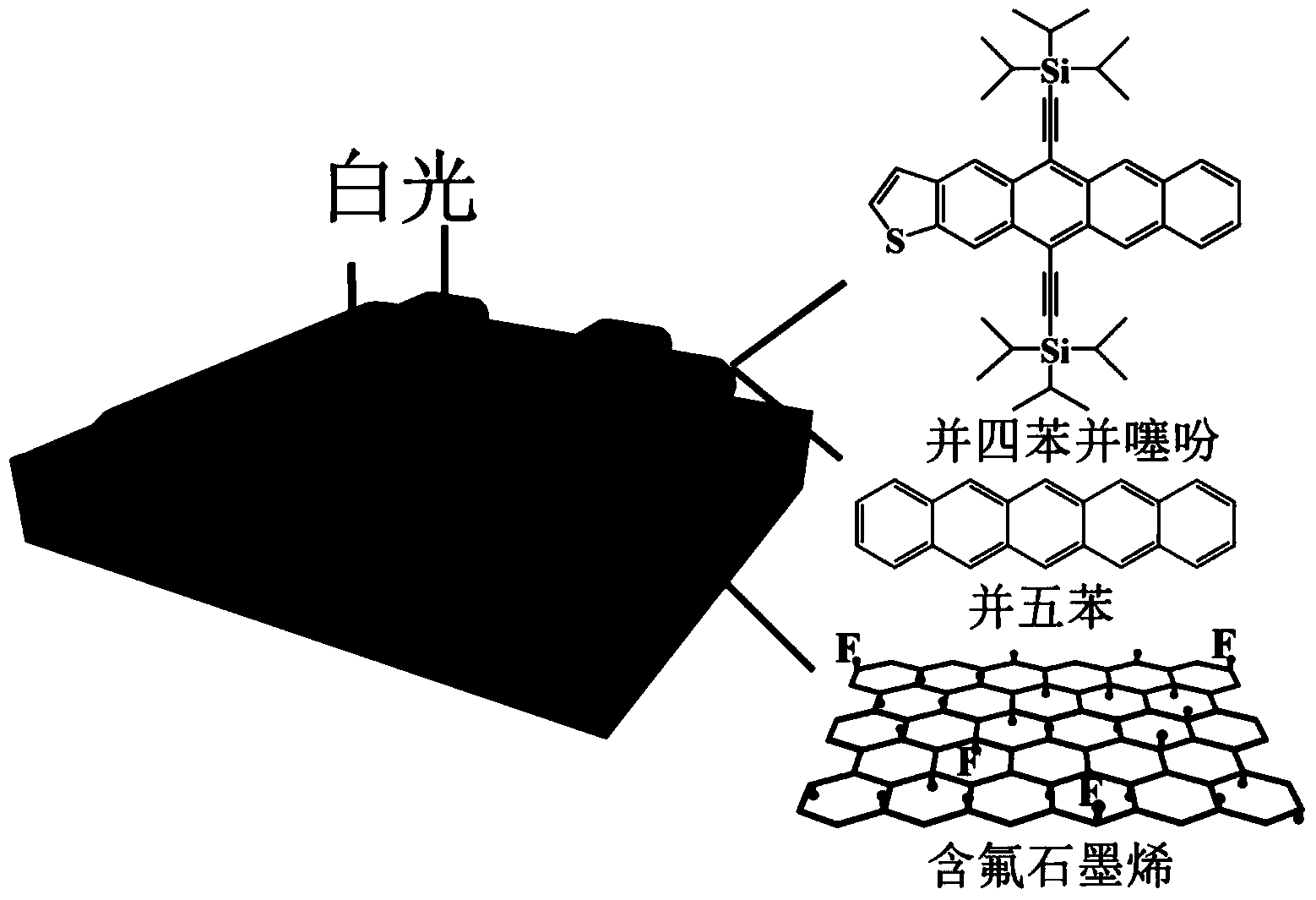

Manufacturing method of fluorine-containing graphene decorative layer organic field effect transistor

A modified layer, graphene technology, applied in the direction of organic semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve problems such as application limitations, achieve high photoresponsivity and photosensitivity, and improve performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] First, perform substrate pretreatment: ultrasonically clean the cut silicon wafers with clean water, secondary water, ethanol, and acetone in sequence, then put them into a mixed solution of sulfuric acid hydrogen peroxide for cleaning, and then clean them with secondary water, ethanol, and acetone Sonicate them separately, and finally dry them with nitrogen gas for later use.

[0025] Secondly, the preparation of the modified layer: evenly spread the fluorine-containing graphene solution on a clean silicon wafer, and obtain a thin film by the method of spinning the film, and then dry the obtained film substrate in a vacuum oven at 80°C for 1 hour to obtain a modified layer substrate.

[0026] Third, the preparation of the thin film: Spread the solution of TIPSEthiotet substituted by triisopropylsilylacetylene evenly on the substrate containing the modified layer, and prepare the modified layer according to the above-mentioned method for the substrate containing the mod...

Embodiment 2

[0030] First, perform substrate pretreatment: ultrasonically clean the cut silicon wafers with clean water, secondary water, ethanol, and acetone in sequence, then put them into a mixed solution of sulfuric acid hydrogen peroxide for cleaning, and then clean them with secondary water, ethanol, and acetone Sonicate them separately, and finally dry them with nitrogen gas for later use.

[0031] Secondly, the preparation of the modified layer: evenly spread the fluorine-containing graphene solution on a clean silicon wafer, and obtain a thin film by the method of spinning the film, and then dry the obtained film substrate in a vacuum oven at 80 ° C for 2 hours to obtain a modified layer substrate.

[0032] Third, the preparation of the film: spread the pentacene solution evenly on the substrate containing the modification layer, and prepare the pentacene film containing the modification layer according to the above method for the substrate containing the modification layer.

[0...

Embodiment 3

[0036] First, perform substrate pretreatment: ultrasonically clean the cut silicon wafers with clean water, secondary water, ethanol, and acetone in sequence, then put them into a mixed solution of sulfuric acid hydrogen peroxide for cleaning, and then clean them with secondary water, ethanol, and acetone Sonicate them separately, and finally dry them with nitrogen gas for later use.

[0037] Secondly, the preparation of the modified layer: evenly spread the fluorine-containing graphene solution on a clean silicon wafer, and obtain a film by the method of spinning the film, and then dry the obtained film substrate in a vacuum oven at 50°C for 3 hours to obtain a modified layer substrate.

[0038]Third, the preparation of the thin film: Spread the solution of TIPSEthiotet substituted by triisopropylsilylacetylene evenly on the substrate containing the modified layer, and prepare the modified layer according to the above-mentioned method for the substrate containing the modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com