Preparation method of molecular sieve micro powder-modified polyvinylidene fluoride membrane

A polyvinylidene fluoride membrane, modification and modification technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effect of simple membrane production process, easy industrialization implementation, and reduced defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Preparation of surface-modified molecular sieves: 13X molecular sieves were dried to constant weight and ground into powder. Add 1 g of dry 13X molecular sieve to 100 mL of sodium stearate solution with a concentration of 0.02 mol / L, react at 60°C for 1 hour, suction filter after the reaction, wash, and dry at 80°C to obtain surface-modified molecular sieve 13X-M -1.

[0020] Preparation of modified polyvinylidene fluoride membrane: Mix 0.4g of the above-mentioned molecular sieve powder 13X-M-1 with 7.0g of polyvinylidene fluoride and 3.0g of polyethylene glycol (M6000) in 40mL of solvent dimethylacetamide. Fully stir at 60°C until the polyvinylidene fluoride is completely dissolved to obtain a uniform casting solution. At 60°C, let stand at constant temperature for defoaming for 12 hours. Pour the casting solution on a glass plate, scrape it into a flat film with a thickness of about 250 microns, put it in deionized water at room temperature, solidify and form it, an...

Embodiment 2

[0022] Preparation of surface-modified molecular sieves: 13X molecular sieves were dried to constant weight and ground into powder. Add 1 g of dry 13X molecular sieve to 100 mL of cetyltrimethylammonium bromide solution with a concentration of 0.04 mol / L, react at 60 °C for 1 h, suction filter after the reaction, wash, and dry at 80 °C to obtain the surface Modified molecular sieve 13X-M-2.

[0023] Preparation of modified polyvinylidene fluoride membrane: Mix 0.6g of the above-mentioned molecular sieve fine powder with 7.0g polyvinylidene fluoride and 6.0g polyethylene glycol (M6000) in 37.0mL solvent dimethylacetamide, fully Stir until the polyvinylidene fluoride is completely dissolved to obtain a uniform casting solution. At 60°C, let stand at constant temperature for defoaming for 12 hours. Pour the casting solution on a glass plate, scrape it into a flat film with a thickness of about 250 microns, put it in deionized water at room temperature, solidify and form it, and...

Embodiment 3

[0024] Embodiment 3, test effect:

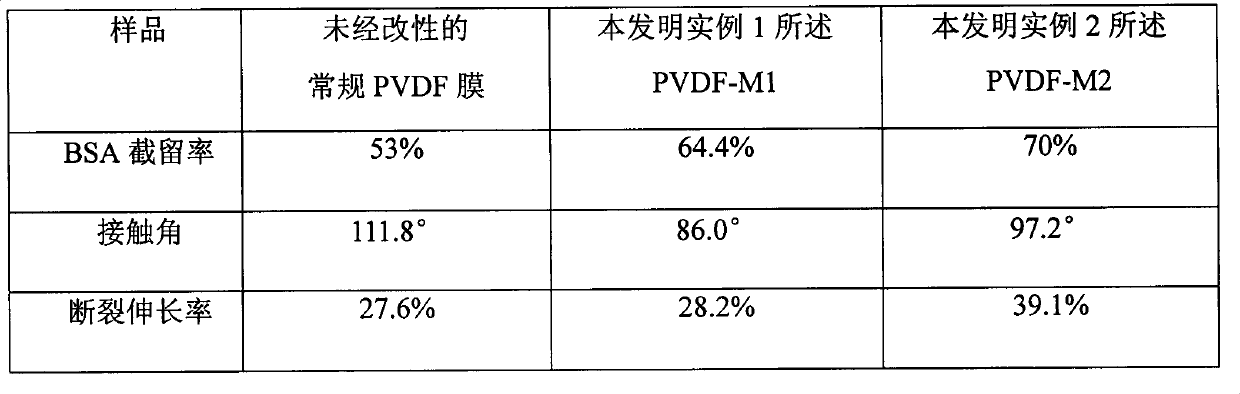

[0025] The conventional PVDF membrane and the two anti-fouling PVDF membranes of the present invention were used for performance testing.

[0026] Use 0.1g / L bovine serum albumin (BSA) solution as the retentate, record the absorbance of the permeate at 278nm at 0.1MPa, query the standard curve to determine its concentration, and calculate the retentivity. Protein is the main food source of bacteria, and its interception can make the bacteria die out naturally.

[0027] The mechanical properties of the film are measured by tensile experiments, and important mechanical properties such as elongation at break are obtained. Test conditions: cut into 5mm wide sample film, gauge 40mm, speed 50mm / min, room temperature. The average value of 3 tests was taken.

[0028] The hydrophilicity of the film is determined by measuring the contact angle, the smaller the contact angle, the stronger the hydrophilicity.

[0029] It can be seen from Table 1 tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com