Functional composite material, manufacturing method thereof and in-situ restoration method for environment

A composite, functional technology for use in the field of polluted air and soil remediation systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

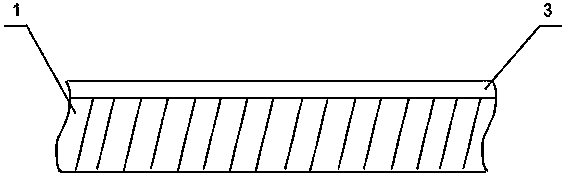

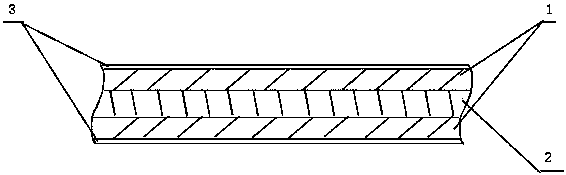

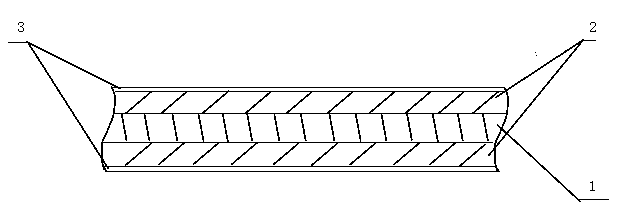

Image

Examples

Embodiment 1

[0096] Preparation As shown in Table 1, add various materials successively and mix and disperse with a mixer, then add the binder and stir well.

Embodiment 2

[0098] As shown in Table 1, the processing method is the same as in Example 1.

Embodiment 3

[0100] As shown in Table 1, the processing method is the same as in Example 1.

[0101] Table I

[0102]

[0103] Prepare the dispersion shown in Table 1, and use a sprayer to spray the super-hydrophilic anti-static anti-bacterial catalytic dispersion, the super-hydrophilic anti-static anti-bacterial catalytic heat-insulating dispersion, and the anti-static anti-bacterial catalytic humidity-adjusting dispersion on three pieces On glass, made by drying.

[0104] The test results of Examples 1-3 are shown in Table 2.

[0105] Table II

[0106]

[0107] It can be seen from Table 2 that the surface materials of Experimental Examples 1 and 2 have excellent self-cleaning effects; Experimental Examples 1, 2 and 3 have good effects in antistatic, antibacterial, and purification of various pollutants; Experimental Example 2 The thermal insulation performance has a good effect, and at the same time, the functional composite material made by the above method can be used alone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com