Medium molecular weight hydroxyethyl starch and its purifying method

A technology of hydroxyethyl starch and purification method, applied in the field of medium molecular weight hydroxyethyl starch, can solve the problems of equipment, facilities, operation, maintenance, high use cost, inability to further improve the quality of feed liquid, inappropriate removal of bacterial endotoxin, etc. , to achieve the effect of reducing the level of bacterial endotoxin and ethylene glycol in the finished product, the method is easy to implement, and the investment in equipment and facilities is not large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

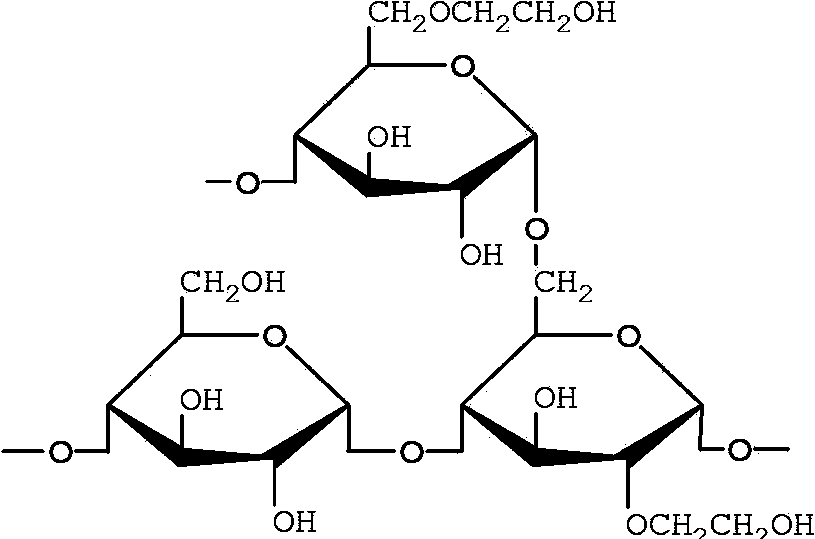

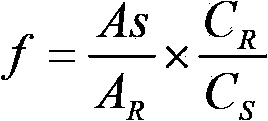

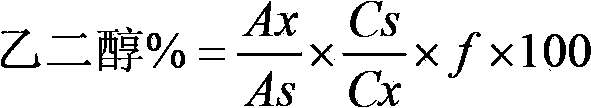

Image

Examples

preparation example Construction

[0056] The purification method of medium molecular weight hydroxyethyl starch of the present invention can be included in the preparation method of following medium molecular weight hydroxyethyl starch, wherein, the preparation method of described medium molecular weight hydroxyethyl starch comprises the following steps:

[0057] 1) Pretreatment and hydrolysis of amylopectin: Pretreatment of amylopectin by elution with positive ion water; then use purified water as solvent to dissolve starch under heating and stirring, and then add inorganic acid to carry out hydrolysis reaction;

[0058] 2) Etherification of hydroxyethyl: add a basic catalyst and an etherification agent to the product obtained in step 1), and carry out etherification reaction under vacuum protection;

[0059] 3) Neutralization and decolorization: add inorganic acid to the product obtained in step 2) to neutralize, then add activated carbon for decolorization and clarification;

[0060] 4) Ultrafiltration: pas...

Embodiment 1

[0077] (1) Pullulan pretreatment

[0078] Add 500L of positive ion water and 100kg of amylopectin into the mixing tank, start stirring and heat preservation to make the two evenly mixed, then centrifuge, and the filter cake is treated amylopectin.

[0079] (2) Hydrolysis

[0080] Add 500L of purified water and 5L of hydrochloric acid solution (36.5% by weight) into the hydrolysis tank, start stirring, then add the pretreated amylopectin obtained in step (1), after stirring evenly, turn on steam to heat and keep warm, the temperature is 92-95 ℃, use the viscosity method to control the hydrolysis process, and stop the hydrolysis when the hydrolysis meets the requirements of the process.

[0081] (3) Etherification

[0082] First, dissolve 16Kg of solid sodium hydroxide in 200L of purified water to make a solution, stir and cool the acid hydrolyzed material obtained in step (2) to 25°C, add NaOH solution evenly to the acid hydrolyzed material, seal the etherification tank, and ...

Embodiment 2

[0096] Similar to Example 1, the difference is that the molecular weight distribution of the hydrolyzate of pullulan is different after hydrolysis, and the refined ultrafiltration feed liquid is concentrated under reduced pressure to a concentration of 48% by weight, and the dehydrated alcohol used during alcohol analysis The weight ratio to the concentrated feed liquid is 2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com