Gas waste, liquid waste and solid waste integrated incinerator

An incinerator and waste liquid technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of single combustion mode, difficult temperature control, insufficient combustion, etc., and achieve efficient incineration treatment, safe and stable operation, and manufacturing process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

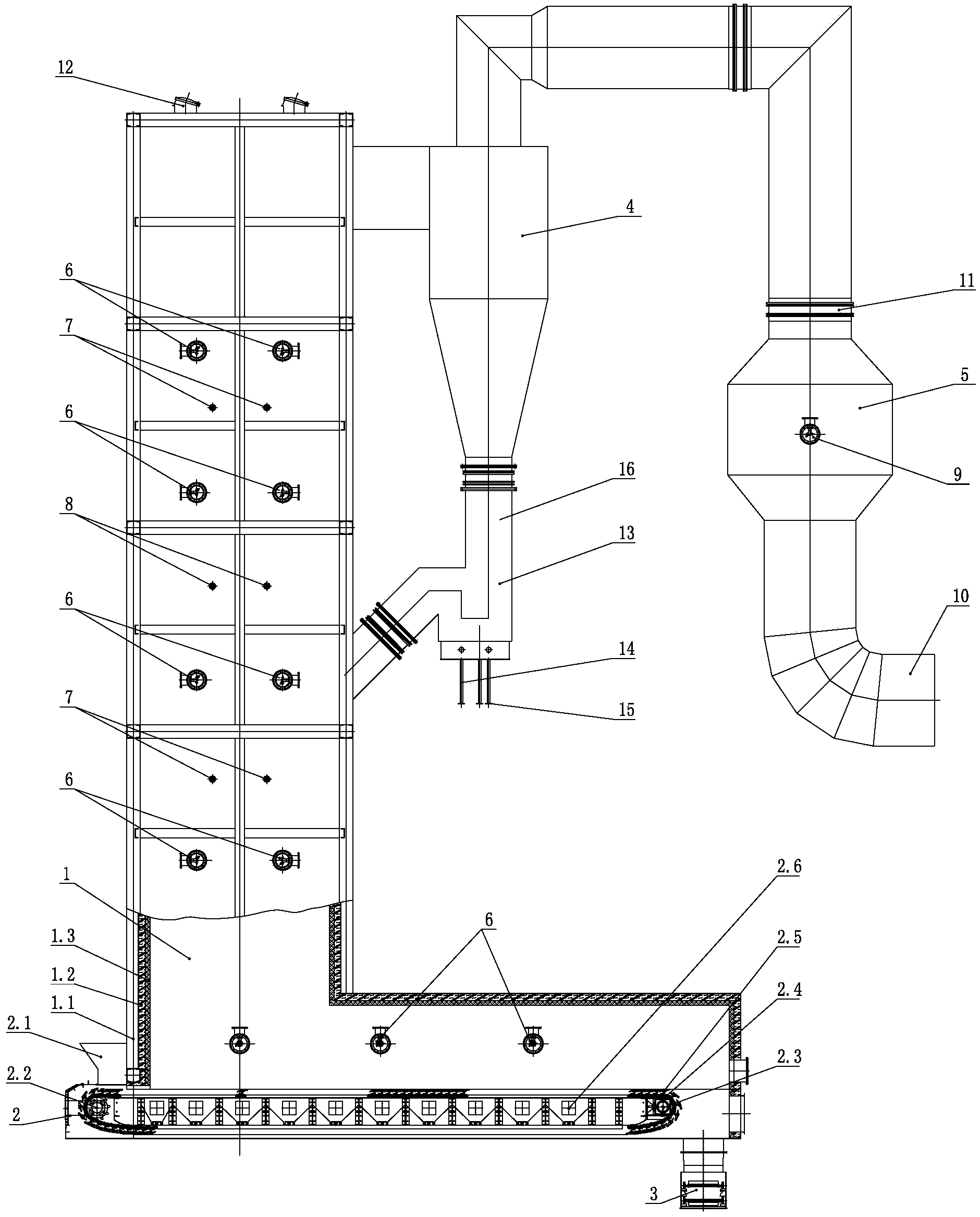

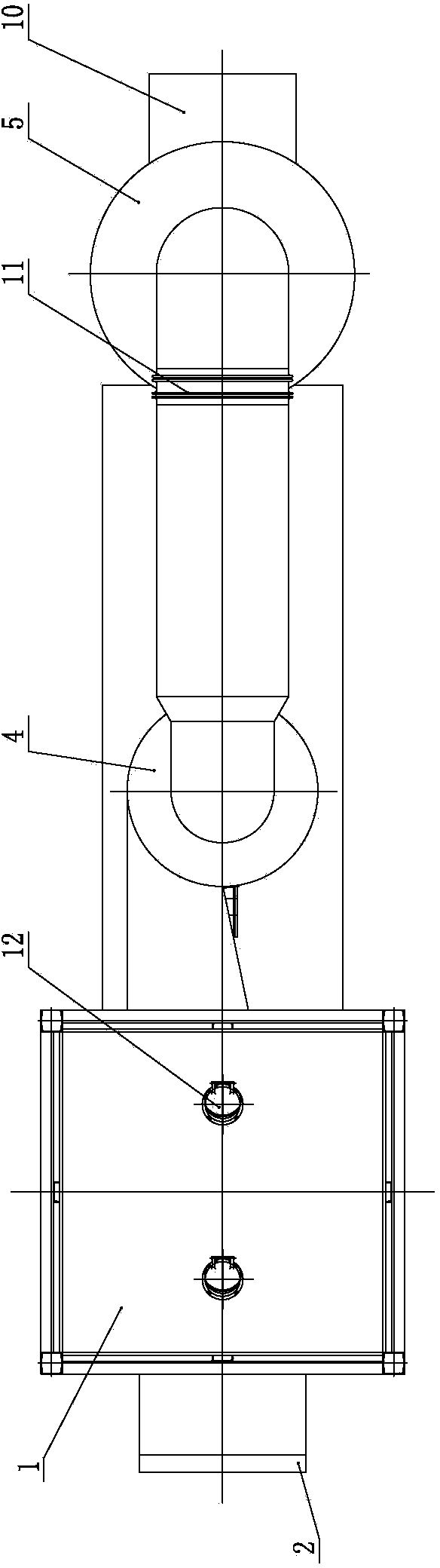

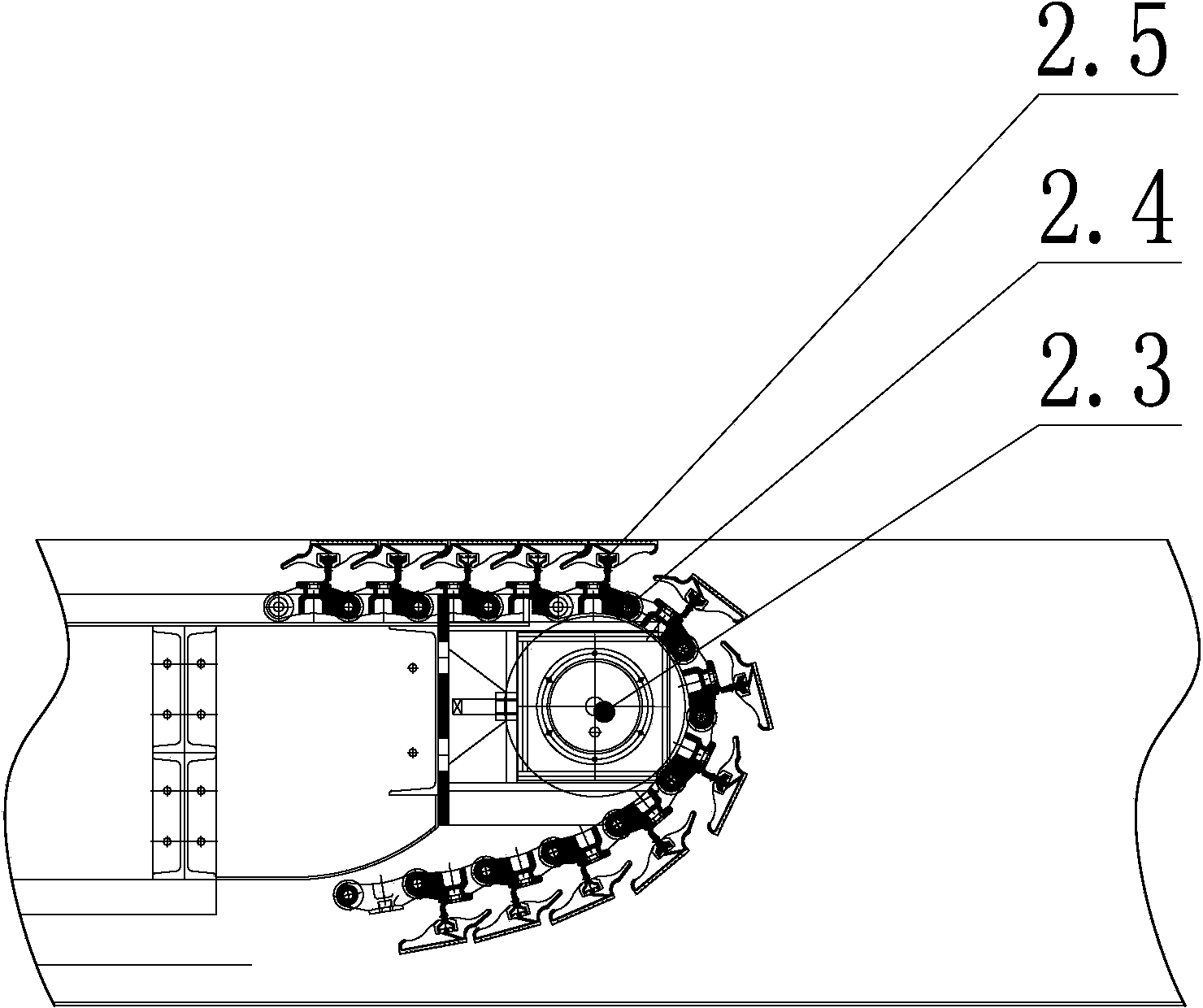

[0035] Such as figure 1 and figure 2 The shown is an integrated incinerator for waste gas, waste liquid, and waste solid "three wastes", including: a primary combustion chamber 1, a spray drying system installed inside the primary combustion chamber 1, and a beam-type chain installed at the bottom of the primary combustion chamber 1 Fire grate 2, water-cooled slag remover 3, cyclone separator 4 and secondary combustion chamber 5;

[0036] The spray drying system includes: several primary combustion chamber burners 6, waste gas nozzles 7 and waste liquid nozzles 8 arranged layered on the inner wall of the primary combustion chamber 1;

[0037] The exhaust gas nozzle 7 and the waste liquid nozzle 8 are arranged between the burners 6 of each adjacent two-layer primary combustion chamber, and the exhaust gas nozzle 7 and the waste liquid nozzle 8 are alternately distributed; as a preference, the waste gas nozzle 7 and the waste liquid nozzle 8 are respectively provided Between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com