Method and system for quickly reducing moisture content in feces and urine from animals and poultry in pretreatment process of organic fertilizer production

An organic fertilizer, livestock and poultry technology, applied in the field of pre-treatment of organic fertilizer production, can solve the problems of biogas slurry accumulation, high water content, environmental pollution, etc., achieve simple equipment structure, reduce water content, and increase economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

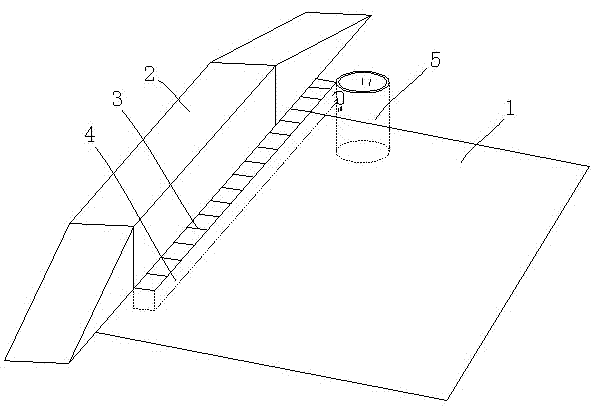

Image

Examples

Embodiment

[0038] The method for rapidly reducing the moisture content in livestock and poultry excrement and urine used in the pretreatment process of organic fertilizer production comprises the following steps:

[0039] (1) Establish a treatment platform locally on the farm; the treatment platform is preferably a fermentation tank, its main function is fermentation, so that the water can be evaporated by fermentation and temperature rise, and it can be set lower than the ground in specific settings (digging pits on the ground), It can also be set higher than the ground (build a pool on the ground), without affecting the use effect, and to a certain extent, it can realize the immediate treatment of livestock and poultry excrement and urine, which greatly saves transportation costs;

[0040] (2) Prepare fermentation bedding, the raw materials of which include at least one of sawdust, rice husk, straw, fungus residue or dry cow dung after dry-wet separation, and lay the fermentation beddin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com