A kind of rapid packaging hot melt adhesive and preparation method thereof

A hot-melt adhesive, fast technology, applied in the direction of adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problems of high elongation, slow curing speed, glue waste, etc., to achieve bonding Strong performance, not easy to coke carbonization, excellent tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

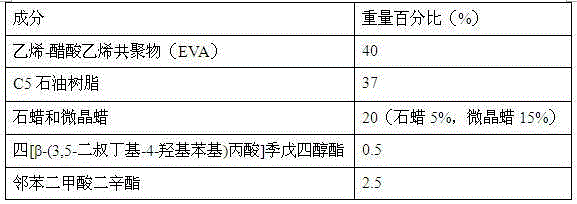

[0052] (1) Accurately weigh the raw materials in the following weight percentages:

[0053]

[0054](2) Add ethylene octene copolymer, C5 petroleum resin, paraffin and microcrystalline wax, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and phthalic acid Add the dioctyl ester into the reaction kettle, raise the temperature to 150°C, and stir at constant temperature for 3 hours to prepare the hot melt adhesive premix.

[0055] (3) The hot-melt adhesive premix that has been mixed is extruded by a twin-screw extruder, and the hot-melt adhesive product is packaged after being cooled by circulating water and pelletized.

Embodiment 2

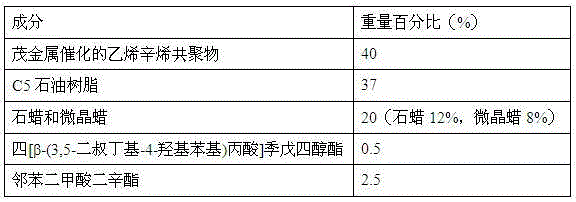

[0057] (1) Accurately weigh the raw materials in the following weight percentages:

[0058]

[0059] (2) Add ethylene octene copolymer, C5 petroleum resin, paraffin and microcrystalline wax, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and phthalic acid Add the dioctyl ester into the reaction kettle, raise the temperature to 150°C, and stir at constant temperature for 3 hours to prepare the hot melt adhesive premix.

[0060] (3) The hot-melt adhesive premix that has been mixed is extruded by a twin-screw extruder, and the hot-melt adhesive product is packaged after being cooled by circulating water and pelletized.

Embodiment 3

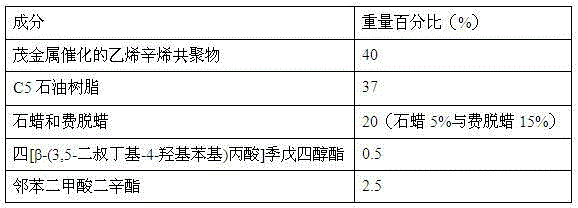

[0062] (1) Accurately weigh the raw materials in the following weight percentages:

[0063]

[0064] (2) Add ethylene octene copolymer, C5 petroleum resin, paraffin and microcrystalline wax, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and phthalic acid Add the dioctyl ester into the reaction kettle, raise the temperature to 150°C, and stir at constant temperature for 3 hours to prepare the hot melt adhesive premix.

[0065] (3) The hot-melt adhesive premix that has been mixed is extruded by a twin-screw extruder, and the hot-melt adhesive product is packaged after being cooled by circulating water and pelletized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com