Preparation method and application of high-purity nanometer silicon

A nano-silicon, high-purity technology, applied in the field of electrochemical metallurgy, can solve the problems of inhibiting the large-scale application of nano-silicon, high cost, and difficulty in large-scale production, and achieve high product purity, high electrolysis efficiency, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1.5 g of commercially available silicon dioxide powder with a purity of 99% was pressed into a silicon dioxide block with a thickness of 4 mm under a mechanical pressure of 5 MPa, and the silicon dioxide block was heated in air at 800 ° C for 0.5 hours to obtain the silicon dioxide The porosity of the block is 20%; the silica block is placed in a conductive metal current collector as the cathode, the graphite rod is used as the anode, and the molten CaCl 2 +NaCl mixed molten salt was used as the electrolyte, under the protection of argon, the electrolysis temperature was 500°C, and the cathode potential was controlled at -0.7V with a fully sealed Ag / AgCl reference electrode to perform constant potential electrolysis; after 30 minutes of electrolysis, the The electrolysis products are washed with water and 0.1mol / L HCl solution respectively, and dried after washing to obtain the required high-purity nano-silicon, the particle size of the product is 10um, and the length of...

Embodiment 2

[0034] 1 g of commercially available silicon dioxide powder with a purity of 99% was pressed into a silicon dioxide disk with a diameter of 20 mm under a mechanical pressure of 6 MPa, and the silicon dioxide disk was heated at 1200 ° C in air for 2 hours to obtain silicon dioxide The porosity of the sheet is 50%; the silicon dioxide sheet is placed in a conductive metal current collector as the cathode, the graphite rod is used as the anode, and the molten CaCl 2 As the electrolyte, under the protection of argon gas, the electrolysis temperature is 850°C, and the cathode potential is controlled at -0.8V with a fully sealed Ag / AgCl reference electrode, and constant potential electrolysis is carried out; after 10 hours of electrolysis, the electrolysis products are respectively used Water and 0.1mol / L H 2 SO 4 The solution is rinsed, and then vacuum-dried to obtain the desired high-purity nano-silicon.

Embodiment 3

[0036]20g of commercially available silicon dioxide powder with a purity of 99% was pressed into a silicon dioxide disk with a diameter of 20mm under a mechanical pressure of 10MPa, and the silicon dioxide disk was subjected to dehydration treatment in air at 100°C; The silicon dioxide sheet is placed in a conductive metal current collector as the cathode, the graphite rod is used as the anode, and the molten CaCl 2 +KCl mixed molten salt was used as the electrolyte, under the protection of argon, the electrolysis temperature was 1000 ° C, and the cathode potential was controlled at -1.0 V with a fully sealed Ag / AgCl reference electrode to perform constant potential electrolysis; after 40 hours of electrolysis, The electrolysis products are respectively washed with water and 0.1mol / L HCl solution, and then vacuum-dried to obtain the required high-purity nano-silicon.

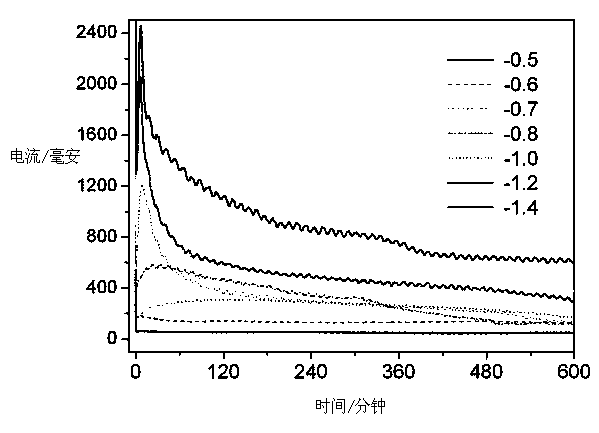

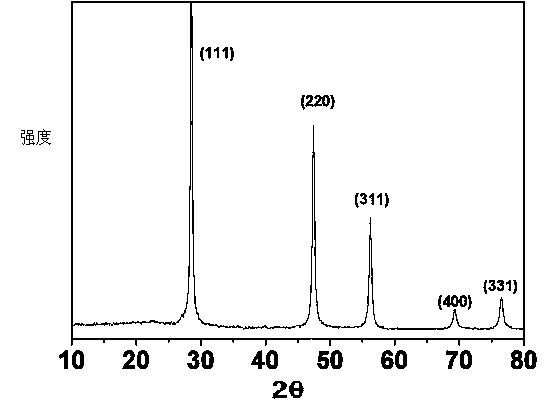

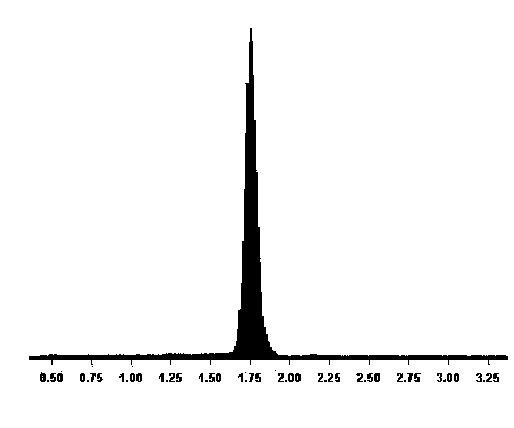

[0037] figure 1 It is a graph of cathodic current and time under different electrolysis potentials, figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com