Method for leaching and measuring molybdenum metal in nickel-molybdenum ore

A nickel-molybdenum ore, leaching technology, applied in the field of nickel-molybdenum ore processing and determination of molybdenum content, can solve the problems of molybdenum concentrate grade and recovery rate, etc., achieve good sample processing and detection methods, less reagent consumption, Strong digestion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] (1) Dissolution of the sample

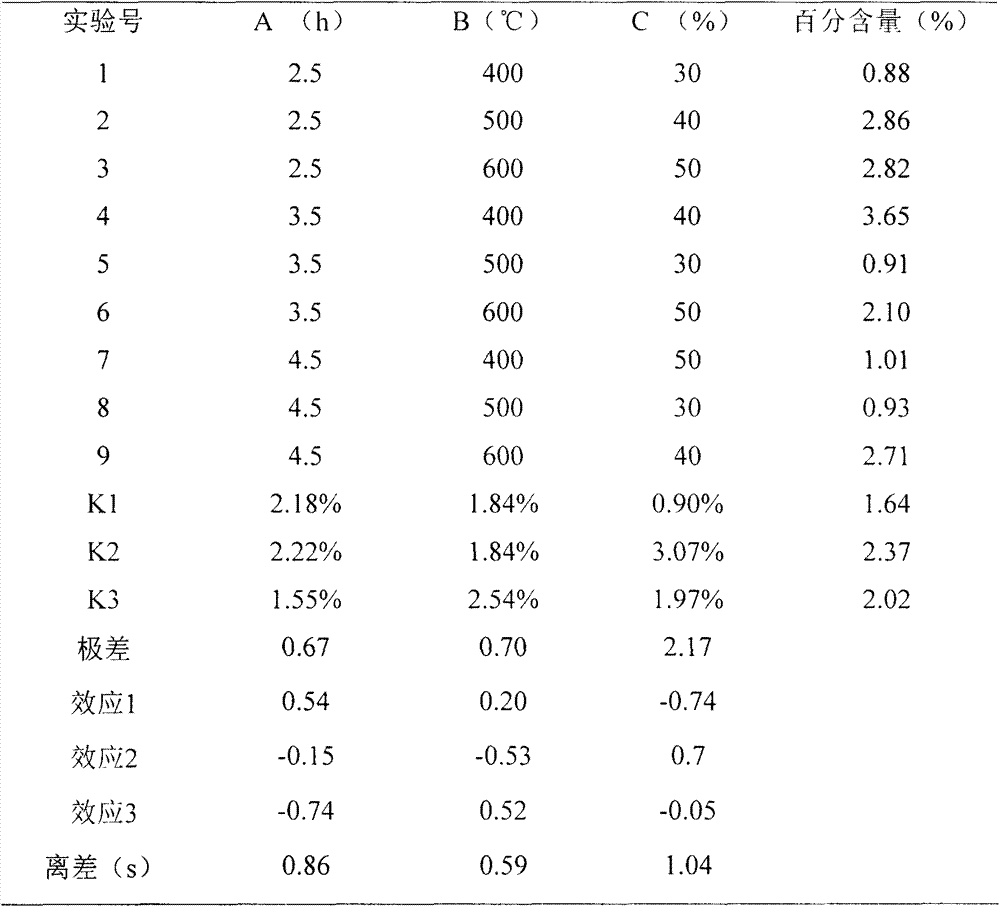

[0018] Molybdenum is stable in air or water at room temperature. The experimental results show that molybdenum can resist the corrosion of dilute sulfuric acid, hydrochloric acid, hydrofluoric acid and phosphoric acid. However, when the temperature reaches 400°C, slight oxidation begins to occur, and when the temperature reaches 600°C, severe oxidation occurs to form molybdenum trioxide. This experiment adopts the orthogonal design method, takes sodium hydroxide as leaching agent, selects roasting time (A), roasting temperature (B), three factors of sodium hydroxide concentration (C), adopt L 9 (4 3 ) orthogonal design, three factors and three levels of experiments were carried out to optimize the extraction conditions of molybdenum content in nickel-molybdenum ore. The factors and levels are shown in Table 1.

[0019] Table 1L 9 (4 3 ) Orthogonal Design

[0020]

[0021] From the range analysis of the table, it can be seen that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com