Nanocomposite bipolar storage battery and preparation process of bipolar plate matrix of nanocomposite bipolar storage battery

A nano-composite material and preparation technology, which is applied in the field of nano-composite bipolar batteries, can solve the problems of plate damage, active substance PbO2, shortening the service life of lead-acid batteries, and large potential differences between lead-acid batteries Long life, high toughness and strength, and the effect of reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

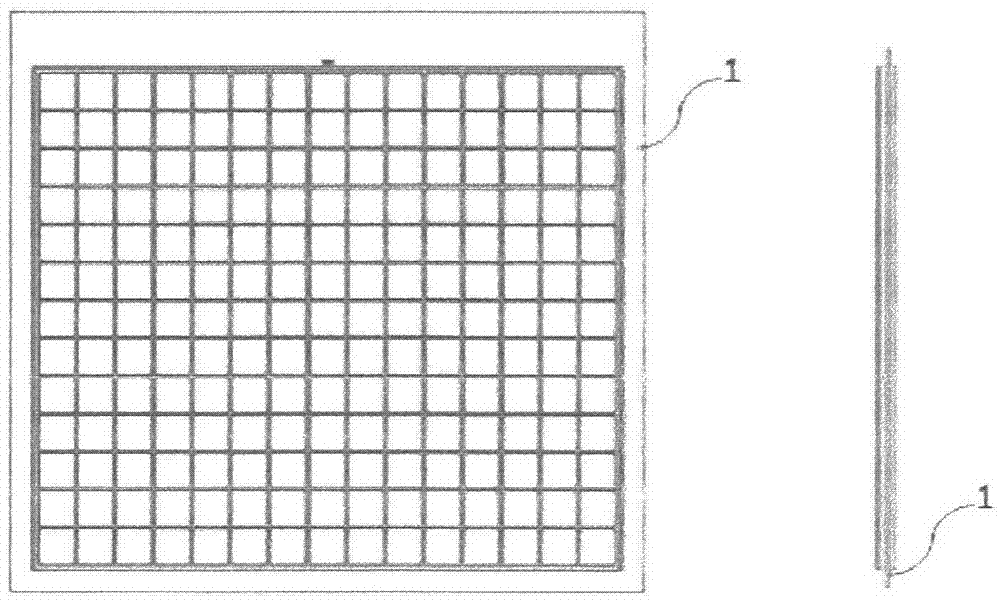

[0026] Such as figure 1 Shown: the preparation method of nanocomposite bipolar battery matrix, its steps are:

[0027] Thermoplastic or thermosetting high molecular polymers and conductive materials are placed in an oven and dried for 0.5 or 1.0 or 1.5 or 2.0 or 2.5 or 3.0 hours at a temperature of 80 or 100 or 110 or 120 or 130 or 140 or 150°C , the thermosetting or thermoplastic polymer is one or more combinations of polyethylene, polypropylene, polybutadiene, polystyrene, polycarbonate, ABS powder and profiles, and the conductive material is metallic lead , metal alloy, acetylene black, carbon black, graphite, carbon nanotubes, polyaniline, titanium oxide, one or more combinations, the particle size range of the conductive material is nanometer or nanometer to micrometer.

[0028] Use 30-100g of the above mixed materials, of which thermoplastic or thermosetting polymers account for 60%-99.9%, conductive materials account for 0.1%-40%, preheat at 100-180°C, pre-press at 0.1...

Embodiment 2

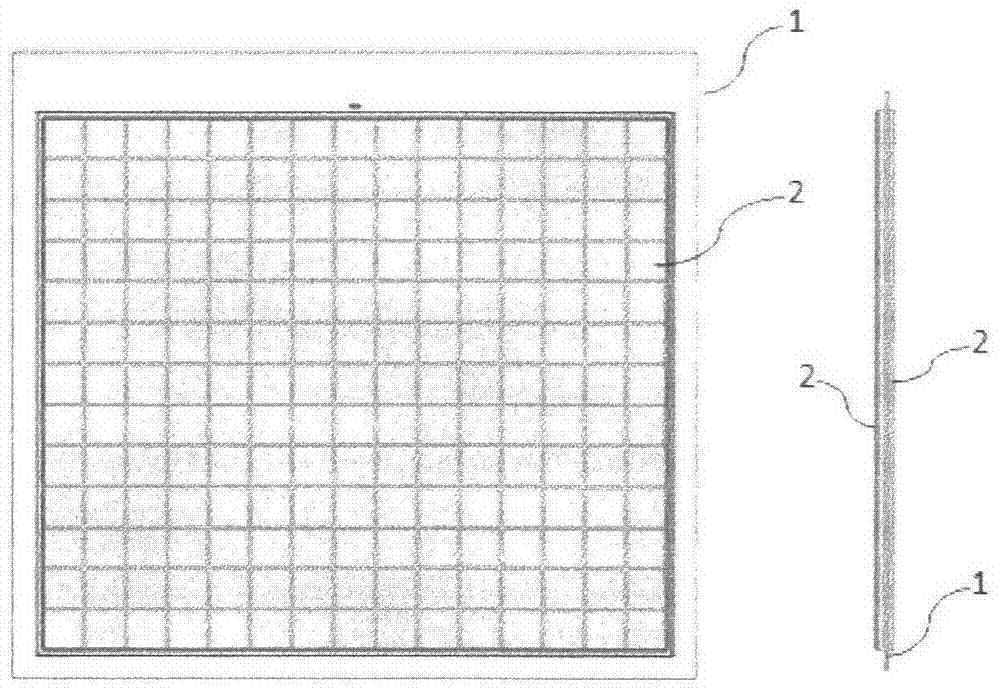

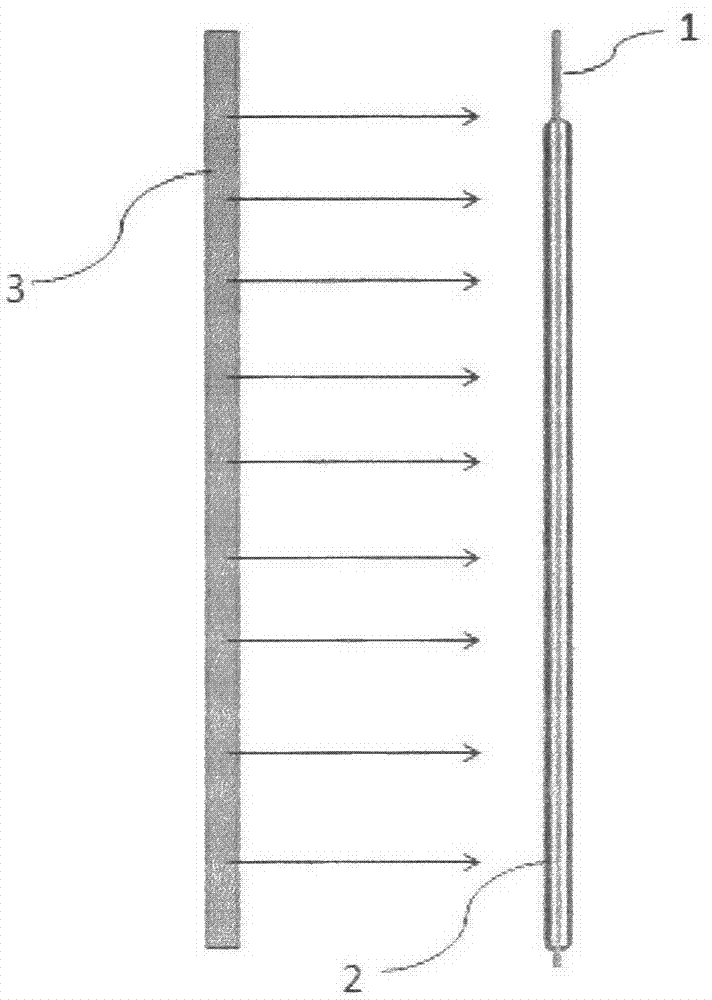

[0037] Such as figure 2 , image 3 Shown: The preparation process of sputtering metal lead on the surface of the nanocomposite bipolar battery substrate:

[0038] The hot-pressed substrate 1 is processed by vacuum magnetron sputtering technology, that is, a balance coil is arranged in the middle of the metal target, which is connected to a power supply, and the magnetic field generated by the coil and the external magnetic field jointly affect the vacuum magnetron sputtering system of the metal. The metal lead sputtering of the substrate 1 is completed to obtain the electrode plate substrate required by the composite.

[0039] The substrate 1 is as described in Example 1, and the details are as above.

[0040] Vacuum magnetron sputtering technology, working pressure 10-6Pa, sputtering chamber temperature 50°C, argon flow rate 50, working voltage 100V, working current 1.8A, magnetic field 350Gs, working frequency 30KHz, precipitation rate 0.3um / min, circulating cooling The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com