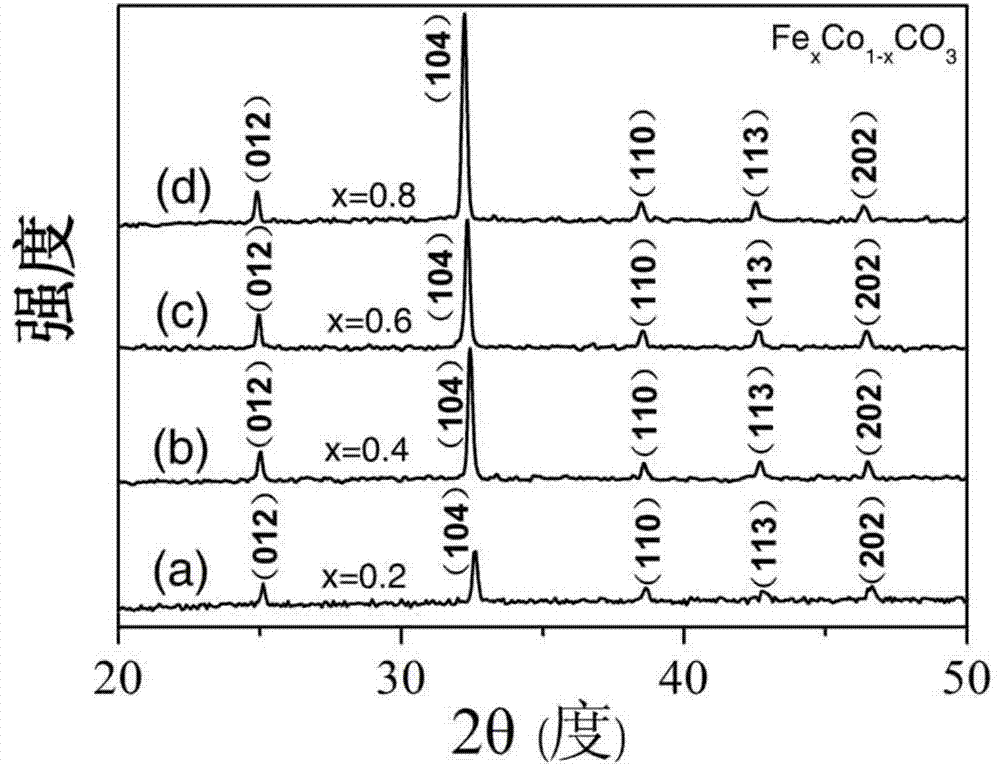

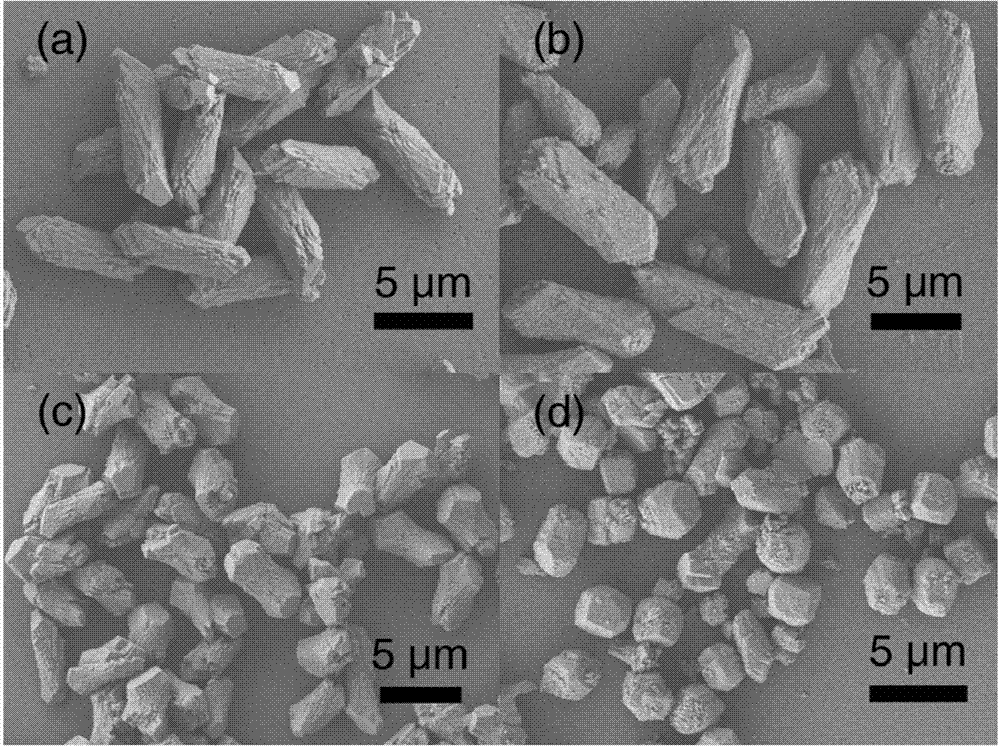

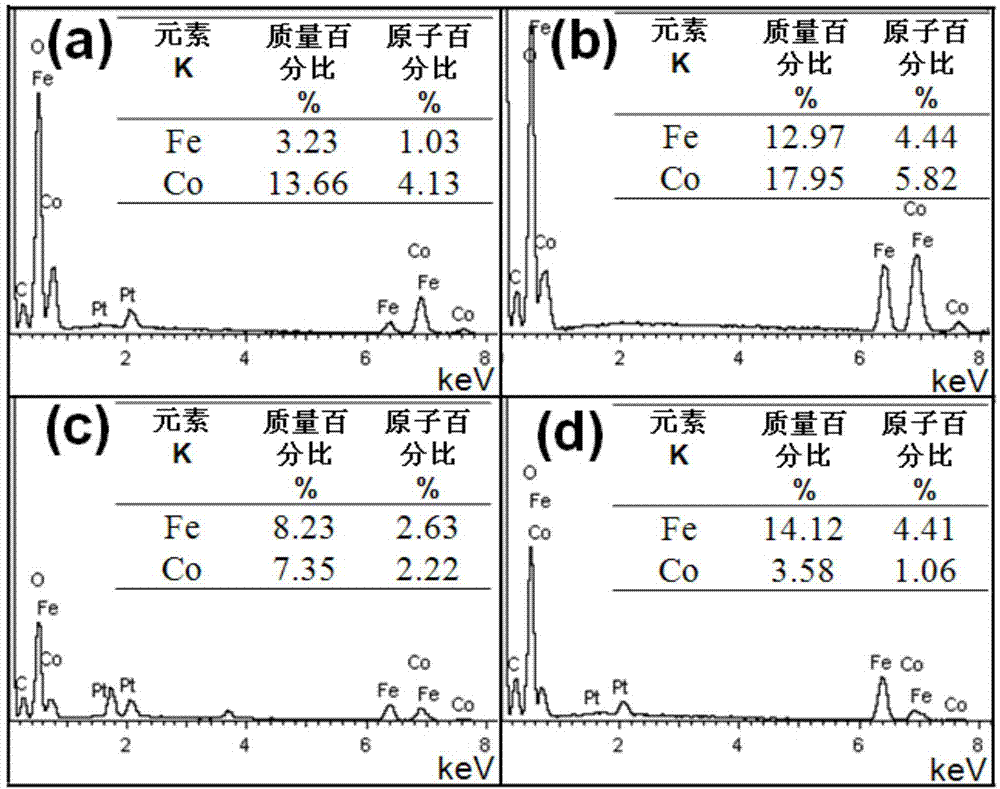

Rod-like cobalt carbonate iron composite material and application thereof

A technology of cobalt iron carbonate and composite materials, which is applied in structural parts, final product manufacturing, electrochemical generators, etc., can solve problems such as product difficulties, and achieve the effects of simple and easy-to-control reactions, good crystallization, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Add ferrous ammonium sulfate and cobalt chloride at a molar ratio of 0.2:0.8 (ie x=0.2) into distilled water at 0.20mmol / 40mL and 0.80mmol / 40mL respectively, and stir until the solution is clear;

[0031] (2) Add sodium bicarbonate in an amount of 3.00mmol / 40mL to the above solution while stirring, and then continue stirring for 10min to obtain a cloudy solution;

[0032] (3) Add sodium pyrophosphate in an amount of 1.00mmol / 40mL to the solution described in step (2) while stirring, and continue stirring for 10 minutes;

[0033] (4) Transfer the solution prepared in step (3) to the reactor, seal it, put it in an oven at 100°C, and react for 9 hours;

[0034] (5) After the reaction is over, cool the reactor to room temperature;

[0035] (6) Discard the supernatant in the reaction kettle, rinse the product with water and ethanol for 3±1 times, and then dry it in an oven at 50°C for 5 hours. The powdery product obtained is the rod-shaped cobalt-iron carbonate composit...

Embodiment 2

[0040] (1) Add ferrous chloride and cobalt nitrate in a molar ratio of 0.4:0.6 (ie x=0.4) into distilled water at 0.40mmol / 40mL and 0.60mmol / 40mL respectively, and stir until the solution is clear;

[0041] (2) Add potassium carbonate in an amount of 2.00mmol / 40mL to the above solution while stirring, and then continue stirring for 15min to obtain a cloudy solution;

[0042] (3) Add diethanolamine in an amount of 2.00mmol / 40mL to the solution described in step (2) while stirring, and continue stirring for 15 minutes;

[0043] (4) Transfer the solution prepared in step (3) to the reactor, seal it, put it in an oven at 120°C, and react for 12 hours;

[0044] (5) After the reaction is over, cool the reactor to room temperature;

[0045] (6) Discard the supernatant in the reaction kettle, rinse the product with water and ethanol for 3±1 times, and then dry it in a 60°C oven for 6 hours. The powdery product obtained is the rod-shaped cobalt-iron carbonate composite material Fe 0....

Embodiment 3

[0050] (1) Add ferrous sulfate and cobalt sulfate at a molar ratio of 0.6:0.4 (ie x=0.6) to distilled water in amounts of 1.20mmol / 40mL and 0.80mmol / 40mL respectively, and stir until the solution is clear;

[0051] (2) Add ammonium carbonate in an amount of 3.00mmol / 40mL to the above solution while stirring, and then continue stirring for 20min to obtain a cloudy solution;

[0052] (3) Add diethanolamine in an amount of 3.00mmol / 40mL to the solution described in step (2) while stirring, and continue stirring for 15 minutes;

[0053] (4) Transfer the solution prepared in step (3) to the reactor, seal it, put it in an oven at 140°C, and react for 14 hours;

[0054] (5) After the reaction is over, cool the reactor to room temperature;

[0055] (6) Discard the supernatant in the reaction kettle, rinse the product with water and ethanol for 3±1 times, and then dry it in an oven at 70°C for 7 hours. The powdery product obtained is the rod-shaped cobalt-iron carbonate composite mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com