Ceria based electrolyte film with preferred orientation and its preparation and application

An electrolyte film and preferential orientation technology, which is applied in the field of cerium oxide-based electrolyte film and its preparation, can solve the problems such as the inability to prepare cerium oxide-based electrolyte film, and achieve the advantages of improving electrocatalytic performance, improving ohmic resistance and reducing polarization resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

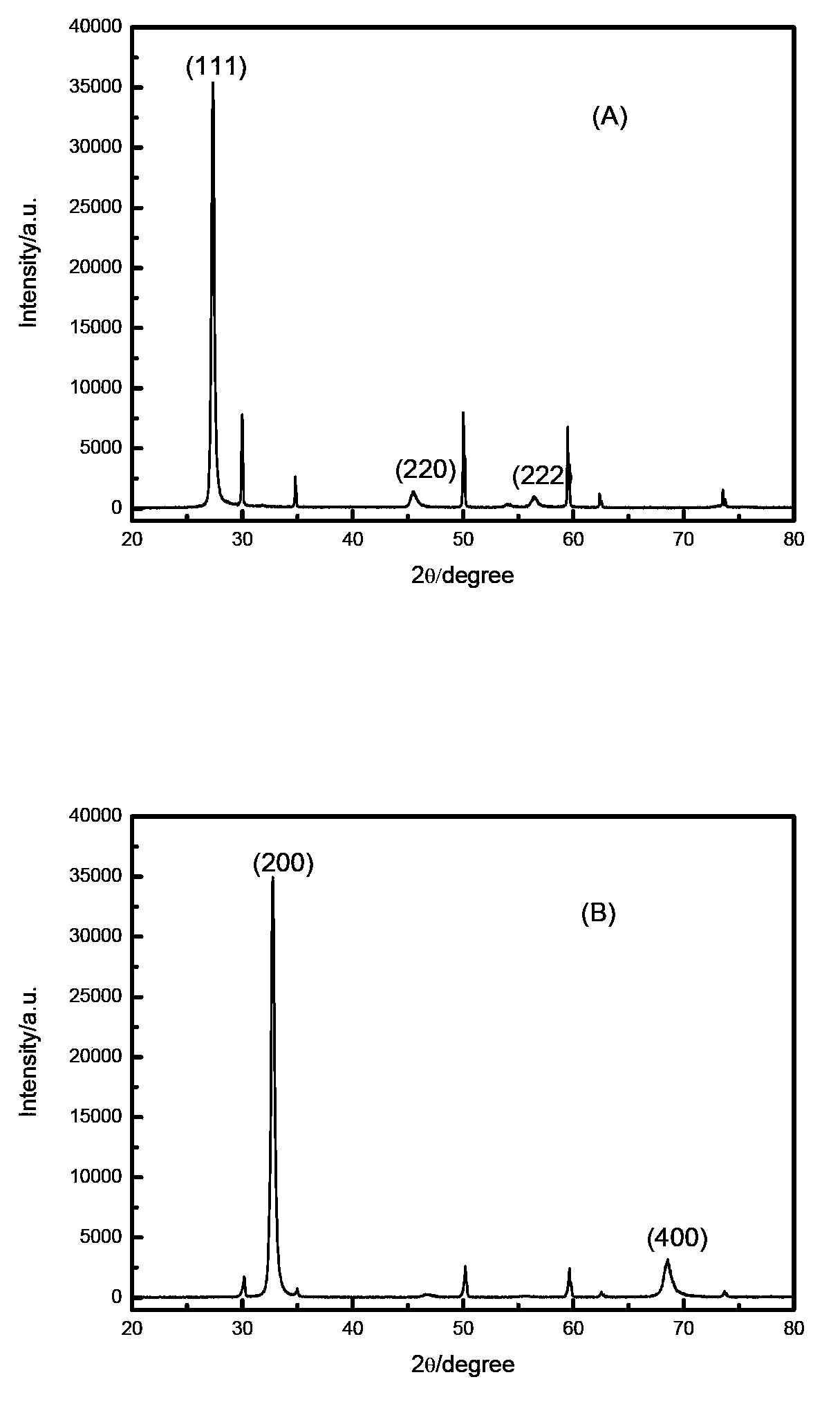

[0020] In nickel oxide with Y 2 o 3 Stable ZrO 2 Composite anode / Y 2 o 3 Stable ZrO 2 Dense Gd with preferred orientation of (100) sputtered on membrane electrode (NiO-YSZ / YSZ) 2 o 3 Doped CeO 2 (Gd 0.1 Ce 0.9 o 1.95 ) Electrolyte interlayer, ultrasonically clean the anode-supported membrane electrode with acetone, ethanol, and distilled water in sequence and dry it, then put it into the vacuum chamber of the magnetron sputtering instrument, adjust the target base distance to about 6cm, and use cerium / Gadolinium alloy material is used as the target material, the purity of the target material is above 99.99%, the cerium / gadolinium molar ratio is 9 / 1, and the vacuum is 8*10 -4 Pa, then heat the substrate table, the temperature rises to 400°C, the flow rate of argon gas is 10.0 sccm, the flow rate of oxygen gas is 1.2 sccm, and the sputtering power is 9W / cm 2 , the sputtering pressure is 0.5Pa, the rotation speed of the substrate stage is set to 5 cycles / min, the thic...

Embodiment 2

[0022] In nickel oxide with Y 2 o 3 Stable ZrO 2 Composite anode / Sc 2 o 3 Stable ZrO 2 Dense Gd with sputtered texture orientation of (110) on the membrane electrode (NiO-YSZ / ScSZ) 2 o 3 Doped CeO 2 (Gd 0.2 Ce 0.8 o 1.9 ) Electrolyte interlayer, adjust the target base distance to about 7cm, use cerium / samarium alloy material as the target material, the purity is above 99.9%, the molar ratio of cerium / samarium is 8 / 2, and vacuumize to 8*10 -4 Pa, then heat the substrate table, the temperature rises to 300°C, the argon flow rate is 40.0sccm, the oxygen flow rate is 5.0sccm, and the sputtering power is 8W / cm 2 , the sputtering pressure is 1.0Pa, the thickness is about 600nm, the rotation speed of the substrate table is set at 10 cycles / min, and the dense Gd 0.2 Ce 0.8 o 1.9 After the sputtering of the interlayer, the dense Gd sputtered texture orientation of (110) on the membrane electrode (NiO-YSZ / ScSZ) was detected by XRD 2 o 3 Doped CeO 2 (Gd 0.2 Ce 0.8 o 1....

example 3

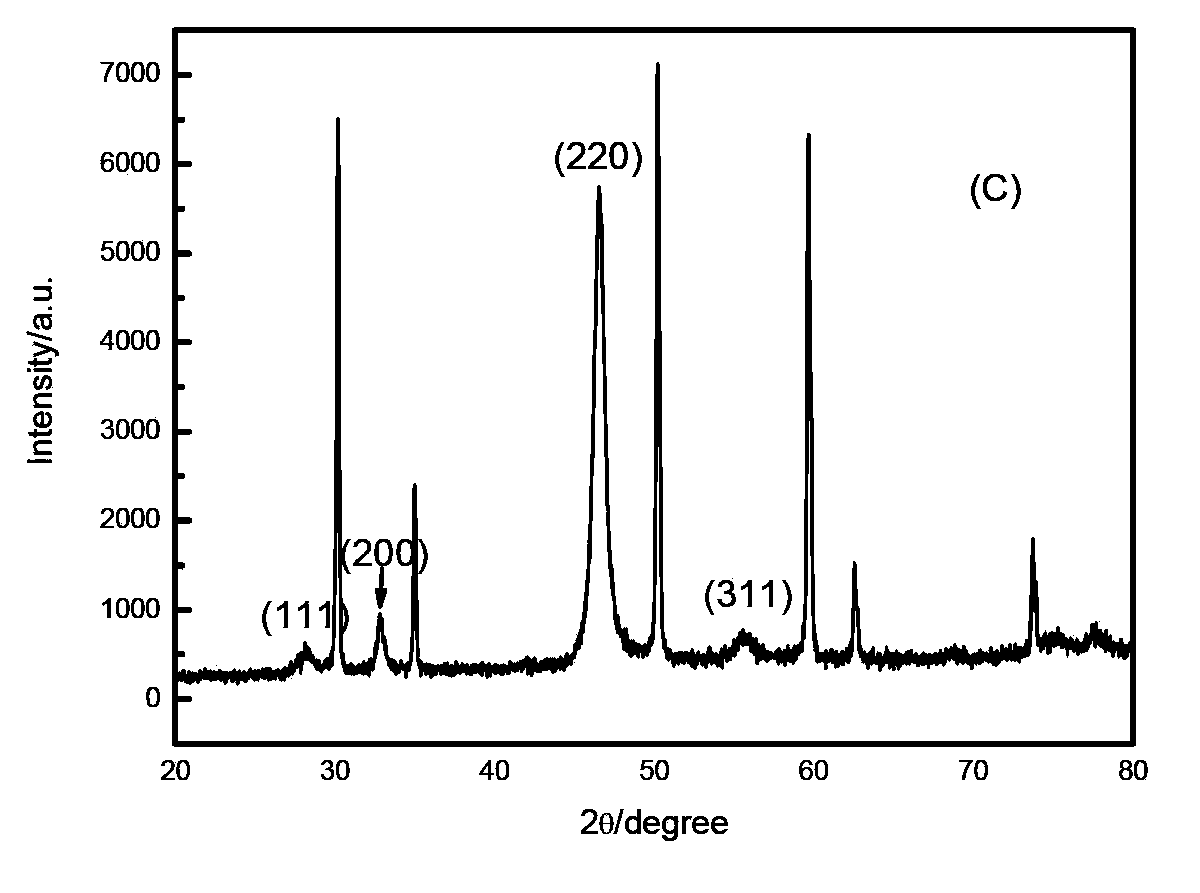

[0024] Sputter deposition of dense Sm with texture orientation of (110) on NiO-SDC anode substrate 2 o 3 Doped CeO 2 (Sm 0.2 Ce 0.8 o 1.9 ) Electrolyte layer, adjust the target base distance to about 6cm, use cerium / samarium alloy material as the target material, the purity is above 99.9%, the molar ratio of cerium / samarium is 8 / 2, and vacuumize to 8*10 -4 Pa, then heat the substrate table, the temperature rises to 400°C, the argon flow is 40.0sccm, the oxygen flow is 5.0sccm, and the sputtering power is 8W / cm 2 , the sputtering pressure is 0.8Pa, the thickness is about 600nm, and the speed of the substrate table is set at 10 revolutions / minute, with Ba 0.5 Sr 0.5 co 0.8 Fe 0.2 o 3 (BSCF) with Sm 0.2 Ce 0.8 o 1.9 Composite materials (where Sm 0.2 Ce 0.8 o 1.9 The mass fraction is 30wt.%) as the cathode, and the battery performance test is carried out on the four-terminal method battery test device, with air as the cathode gas and wet hydrogen as the anode gas. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com