A kind of preparation method of liquid compound enzyme with high stability for feeding

A liquid compound enzyme and high stability technology, applied in biochemical equipment and methods, enzyme stabilization, enzymes, etc., can solve the problems of high equipment and material input costs, blockage and damage of spray system, waste of enzyme activity, etc., to achieve equipment and The effect of low material input cost, reduced production input and cost, and high stability of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

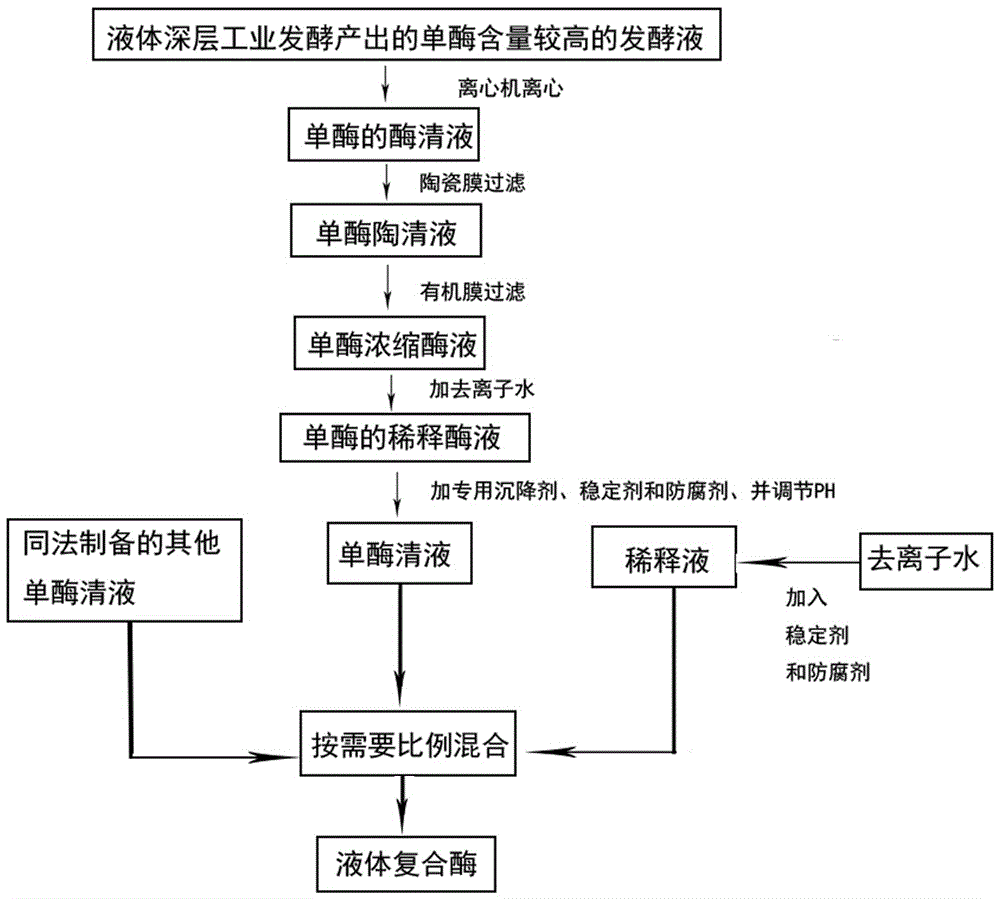

[0046] 1. If figure 1 As shown, according to the preparation process, the engineering strains with high single-enzyme production are selected for large-scale liquid submerged industrial fermentation. The liquid submerged fermentation technology is an existing mature technology, which will not be repeated here. Glycanase fermentation broth, mannanase fermentation broth, and cellulase fermentation broth are passed through a disc centrifuge respectively, and the clear liquid is passed through a ceramic membrane with a pore size of 0.10 μm. The concentrated enzyme solution of carbohydrase is diluted to 50000U / g with deionized water, the concentrated enzyme solution of mannanase is diluted to 50000U / g with deionized water, and the concentrated enzyme solution of cellulase is diluted to 3000U / g with deionized water.

[0047] 2. Add sedimentation agent, stabilizer and preservative in proportion to the diluted enzyme solution. The specific ratio is diluted enzyme solution: potassium a...

Embodiment 2

[0051] Processing method is the same as embodiment one, prepares liquid compound enzyme 1000kg containing four kinds of enzymes of xylanase, cellulase, mannanase, phytase, adds the xylanase liquid after settlement in the finished product mixing tank 201kg, mannan enzyme solution 48kg, cellulase 333.3kg, phytase 100Kg, diluent 317.7kg, after mixing evenly, the liquid compound enzyme product was obtained. After testing, xylanase 11834U / ml, mannanase 2406U / ml, cellulase 1024U / ml, phytase 5437U / ml.

Embodiment 3

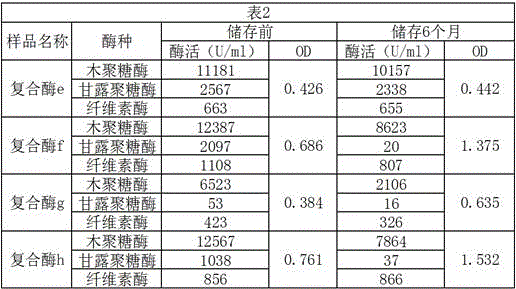

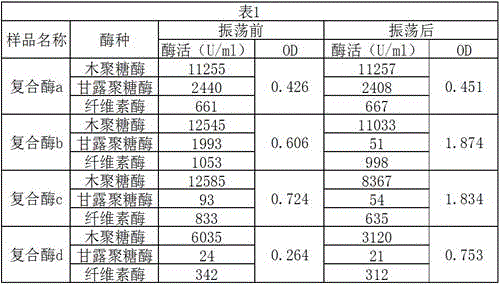

[0053] In order to prove the stability of the liquid compound enzyme prepared by the present invention, and quickly evaluate its stability during long-term storage and transportation, this embodiment uses chemical kinetics to quantify the effects of external factors such as temperature, humidity, pressure, and light on qualitative changes. The influence of the reaction, by controlling the product in an environment where one or more external factors are higher than the normal level, the speed of qualitative change can be accelerated in a short period of time to determine whether the product has deteriorated. Oscillation and temperature are often important factors in product quality degradation. The liquid compound enzyme on the purchasing market and the liquid compound enzyme that the present invention makes carry out accelerated experiment contrast, and concrete experiment is as follows:

[0054] Put 100ml of liquid compound enzyme into a 500ml Erlenmeyer flask, seal the mouth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com