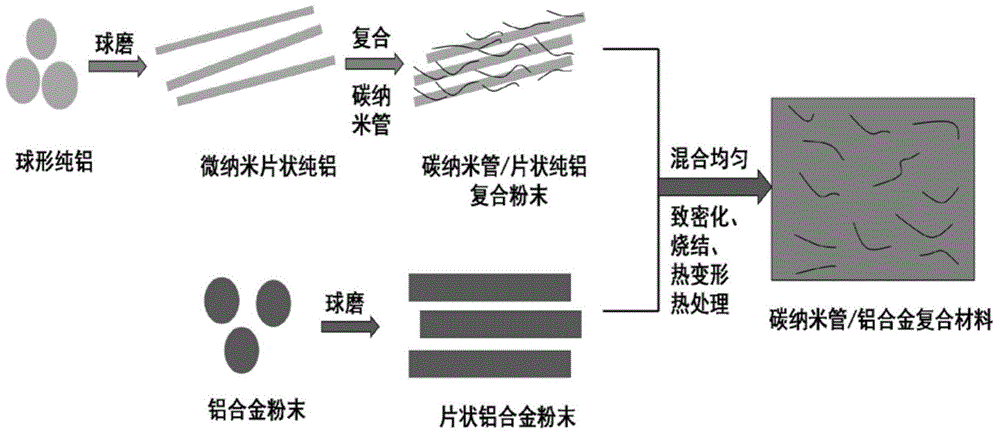

Powder metallurgy preparation method of carbon nanotube reinforced aluminium alloy composite material

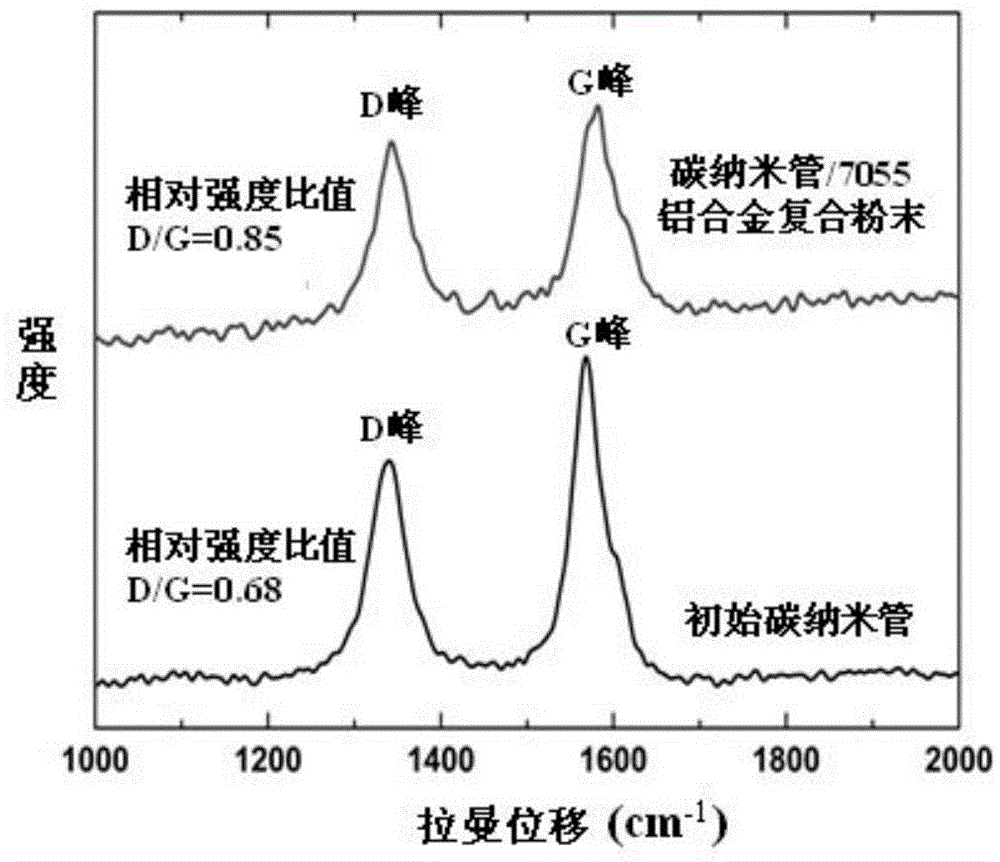

A technology of carbon nanotubes and composite materials, which is applied in the field of metal matrix composite materials, can solve the problems of difficult dispersion and easy hydrolysis, and achieve the effect of small structural damage, good compatibility and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Carbon nanotube reinforced 7055 aluminum alloy (containing 1wt.% of carbon nanotubes)

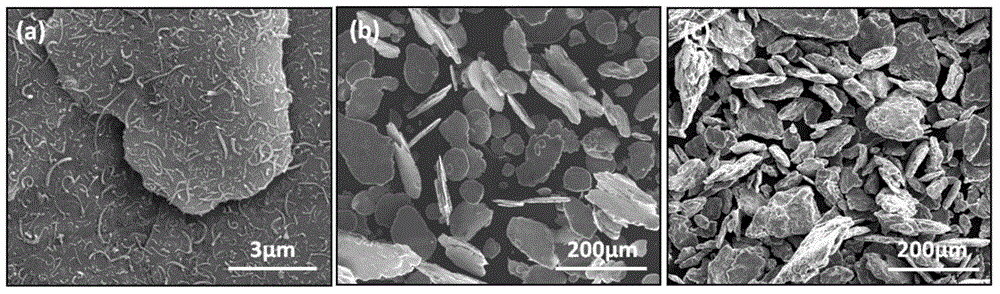

[0039] Take 50g of pure aluminum powder with a particle size of 10μm and place it in a stirring ball mill, use anhydrous alcohol as the solvent, add 2g of titanate as the ball milling process control agent, and use stainless steel balls as the ball milling medium. The ball-to-battery ratio is 20:1. Ball milled at a speed of 100 revolutions / min for 6 hours, filtered and dried to obtain flake aluminum powder with a flake diameter of about 60 μm, a flake thickness of about 200 nm, and a diameter-to-thickness ratio of about 300.

[0040] 1g of carboxylated carbon nanotubes is ultrasonically dispersed to prepare an aqueous carbon nanotube slurry. Add 50 g of flaky aluminum powder to the polyvinyl alcohol solution and stir for 30 minutes, and filter to remove excess polyvinyl alcohol solution. Add the flake aluminum powder to the diluted carbon nanotube water slurry (concentration of 0.3g / L), ...

Embodiment 2

[0052] Carbon nanotubes reinforced 2014 aluminum alloy (2wt.% of carbon nanotubes)

[0053] Take 50g of pure aluminum powder with a particle size of 10μm and place it in a stirring ball mill, use anhydrous alcohol as the solvent, add 2g of titanate as the ball milling process control agent, and use stainless steel balls as the ball milling medium. The ball-to-battery ratio is 20:1. Ball milled at a speed of 100 revolutions / min for 8 hours, filtered and dried to obtain flake aluminum powder with a flake diameter of about 60 μm, a flake thickness of about 100 nm, and a diameter-to-thickness ratio of about 600.

[0054] 2g of carboxylated carbon nanotubes is ultrasonically dispersed to prepare an aqueous carbon nanotube slurry. Add 50 g of flaky aluminum powder to the polyvinyl alcohol solution and stir for 30 minutes, and filter to remove excess polyvinyl alcohol solution. Add the flake aluminum powder to the diluted carbon nanotube water slurry (concentration of 0.3g / L), stir until...

Embodiment 3

[0059] Carbon nanotube reinforced 5083 alloy (containing 2wt% carbon nanotube)

[0060] Prepare flaky pure aluminum powder according to the scheme of Case 1, then add the flaky aluminum powder to the mixed solution of polyethylene glycol and ferric nitrate and stir for 1 hour, filter and vacuum dry, and heat to 600 in a vacuum tube furnace under argon atmosphere. After keeping the temperature at ℃ for 3h, the temperature is lowered to obtain 4wt% carbon nanotube / pure aluminum flake composite powder.

[0061] Put 50g of spherical 5083 aluminum alloy powder with a particle size of 30μm in a stirred ball mill, use anhydrous alcohol as solvent, add 2g of titanate as ball milling process control agent, use stainless steel ball as ball milling medium, and the ratio of ball to material is 20:1. Ball milled at 100 revolutions / min for 6 hours, filtered and dried to obtain flake 5083 aluminum alloy powder.

[0062] Mix the above 50g carbon nanotube / pure aluminum composite powder with 50g flak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com