Preparation method for grafted and modified silicon-based solid-state-amine carbon dioxide adsorption material

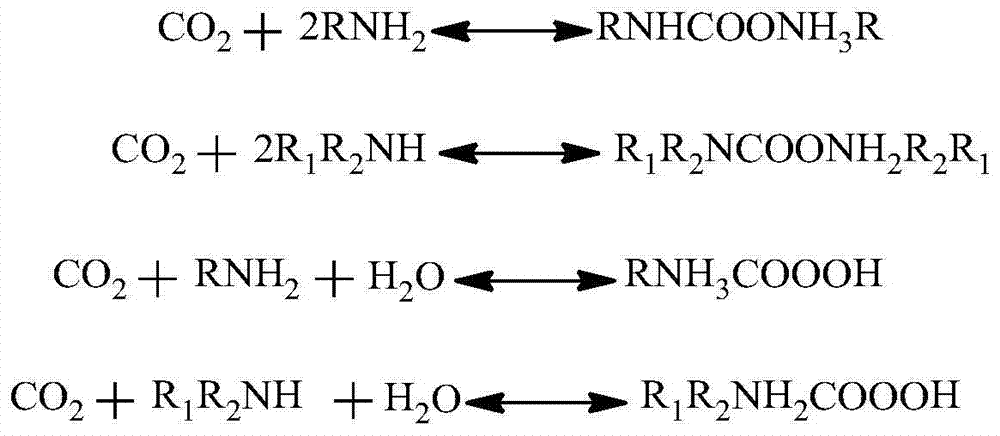

An amine carbon dioxide and adsorption material technology is applied in the field of preparation of silicon-based solid amine carbon dioxide adsorption materials, which can solve the problems of high energy consumption and affecting use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

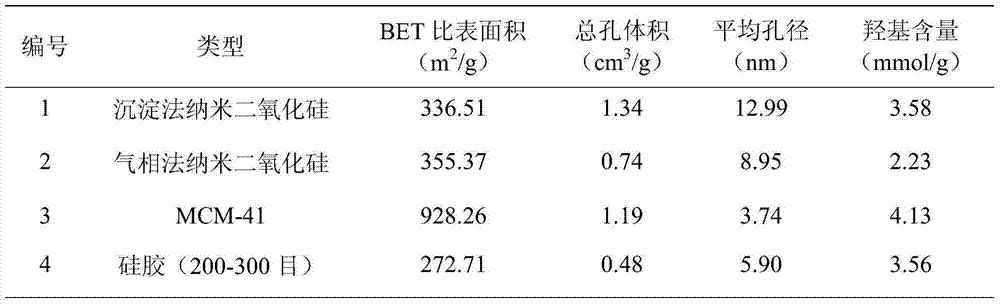

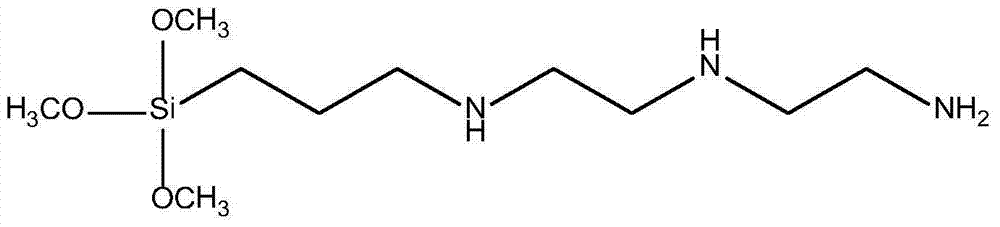

[0022] A method for preparing a grafted modified silicon-based solid amine carbon dioxide adsorption material, comprising drying the precipitated silica at 110°C for 2-3 hours, weighing 10g of the dried precipitated silica and adding it to 250ml three-neck flask, then add 200ml of dry toluene to the flask, put the flask into an oil bath and fix it, connect the reflux condenser to the flask, and put the magnetic stirrer rotor into the flask at the same time, and then pour the Nitrogen was introduced into the flask to discharge the air in the flask, and then the flask was sealed, stirred at a constant speed and heated to 90°C. After the temperature was stabilized at 90°C, 4ml of divinyltriaminopropyltrimethoxysilane was added to the Keep stirring at a constant speed in the flask, and let the above reaction proceed at 90°C for 6 hours. After the reaction is complete, filter the synthesized material and rinse it twice with 100ml of absolute ethanol, and then dry it in a vacuum oven...

Embodiment 2

[0024] A preparation method of a grafted modified silicon-based solid amine carbon dioxide adsorption material, drying fumed silicon dioxide at 110°C for 2-3 hours, weighing 5g of the dried fumed silicon dioxide and adding it to 250ml three-neck flask, then add 100ml dry toluene to the flask, put the flask into an oil bath and fix it, connect the reflux condenser to the flask, and put the magnetic stirrer rotor into the flask at the same time, and then put it into the flask Nitrogen was introduced into the flask to discharge the air in the flask, and then the flask was sealed, stirred at a constant speed and heated to 90°C. After the temperature was stabilized at 90°C, 2ml of divinyltriaminopropyltrimethoxysilane was added to the Keep stirring at a constant speed in the flask, and let the above reaction proceed at 90°C for 6 hours. After the reaction is complete, filter the synthesized material and rinse it twice with 100ml of absolute ethanol, and then dry it in a vacuum oven ...

Embodiment 3

[0026] A preparation method of a grafted modified silicon-based solid amine carbon dioxide adsorption material, drying MCM-41 at 110°C for 2-3 hours, weighing 10g of dried MCM-41 and adding it to a 250ml three-neck flask Then add 200ml of dry toluene to the flask, put the flask into an oil bath and fix it, connect the reflux condenser to the flask, put the magnetic stirrer rotor into the flask, and then feed nitrogen into the flask To discharge the air in the flask, then seal the flask, stir it at a constant speed and heat it to 90°C, after the temperature is stabilized at 90°C, add 4ml of divinyltriaminopropyltrimethoxysilane into the flask, and Keep stirring at a constant speed, and let the above reaction proceed at 90°C for 6 hours. After the reaction is completed, filter the synthesized material and wash it twice with 100ml of absolute ethanol, and then dry it in a vacuum oven at 80°C for 12 hours. Yes, the air pressure in the oven is <1mm Hg. The sample was named as DETA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com