Laser alloying powder and application of laser alloying powder in steel cylinder circular mould laser surface alloying

A laser alloying and powder technology, applied in metal material coating process, coating and other directions, can solve the problems of reduced toughness of steel cylinder ring die, affecting production efficiency, high price of steel, etc. The effect of increased volume and good red and hard performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

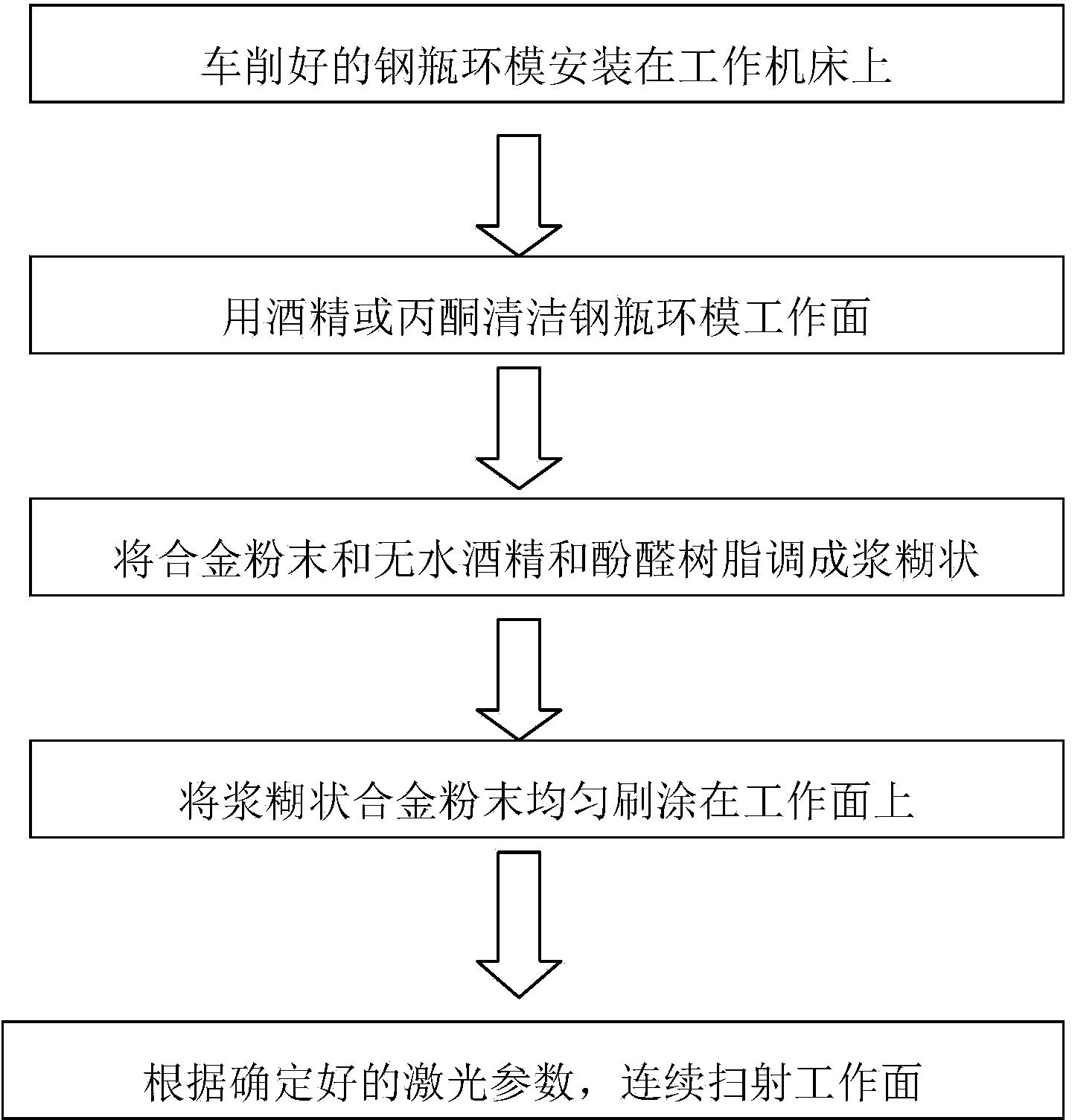

[0035] The inventive method is used for strengthening the method step of H13 steel cylinder ring die as follows:

[0036] (1) Turn the working surface of the steel cylinder ring die to be processed flat with an ordinary lathe, and then install the turned steel cylinder ring die on the machine tool, the axis of which is along the horizontal direction and can rotate around the axis;

[0037] (2) Clean the working surface of the cylinder ring die with alcohol or acetone until the working surface is free of oil and clean;

[0038] (3) Use anhydrous alcohol to mix the laser alloy powder and phenolic resin into a paste-like alloy coating, dip the coating with a soft brush, and brush it evenly on the working surface with a coating thickness of 0.12mm, and let it dry dry or dry, the laser alloy powder is composed of tungsten carbide powder, boron carbide powder, molybdenum powder, chromium powder and nickel powder, the weight ratio is tungsten carbide powder: boron carbide powder: mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com