Fine coal low-temperature destructive distillation kiln

A low-temperature, kiln technology, applied in the field of dry distillation furnace, can solve the problems of worsening the on-site operating environment, increasing the transportation cost, restricting the use of blue carbon, etc., and achieving the effect of facilitating gas collection, convenient operation and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

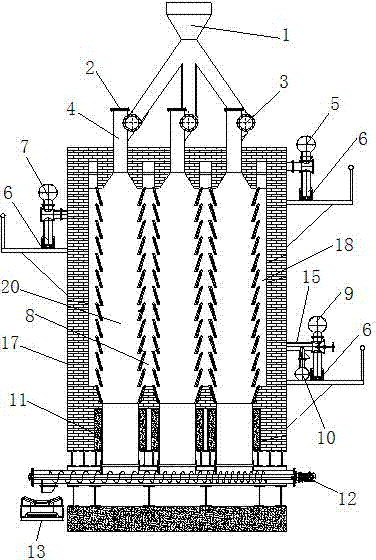

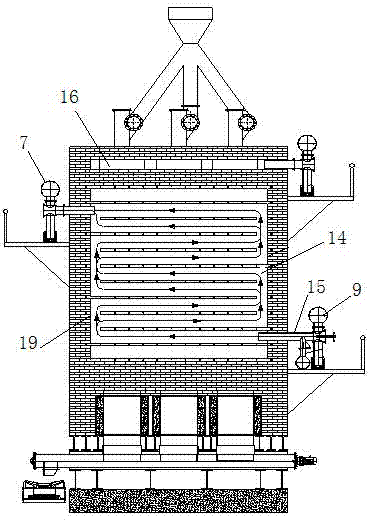

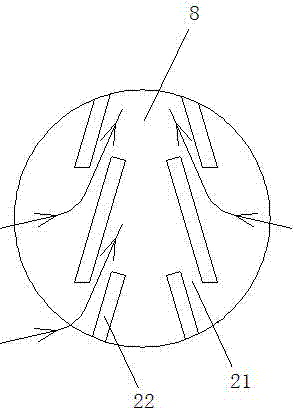

[0016] Such as figure 1 , 2 As shown in , 3, a pulverized coal low-temperature dry distillation kiln comprises a furnace body 17, a fire wall 19 is arranged in the furnace wall of the furnace body 17, and a fire channel 14 is arranged inside the fire wall 19, and the upper part of the fire channel 14 is connected with the smoke exhaust The pipeline 7 is connected, the bottom of the fire channel 14 is connected with the gas burner 15, the gas burner 15 is connected with the gas pipeline 9 and the air pipeline 10, and at least one carbonization chamber 18 is arranged on the inner side of the fire wall 19, and the top of the carbonization chamber 18 is connected with the The feeding port 4 is connected, and the upper part of the feeding port 4 is connected with the frequency conversion screw feeder 3, and the upper part of the frequency conversion screw feeding machine 3 is connected with the furnace top silo 1, and the side of the feeding port 4 is horizontally arranged with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com